Breakthrough Reactor Revolutionizes Direct Air Capture While Cutting Energy Costs!

2024-10-30

Author: John Tan

Breakthrough Reactor Revolutionizes Direct Air Capture While Cutting Energy Costs!

In an exciting development for climate science, researchers at Rice University have unveiled a groundbreaking electrochemical reactor designed to significantly lower energy consumption in direct air capture (DAC) — a technology that extracts carbon dioxide directly from the atmosphere.

This innovative reactor represents a pivotal advancement in the quest to mitigate the impacts of emissions on our planet. Researchers believe it could play a crucial role in creating scalable and efficient carbon reduction strategies, which is urgently needed in our fight against climate change.

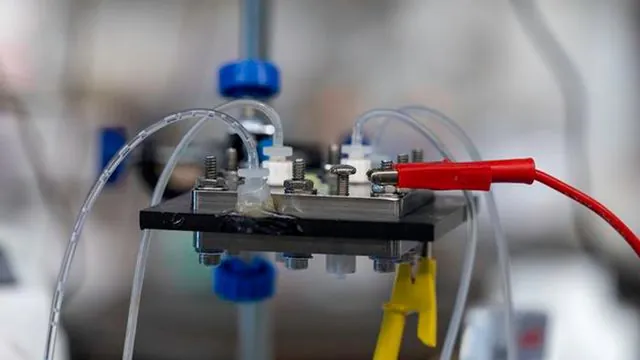

Published in *Nature Energy*, the study showcases a modular reactor with a unique three-chambered configuration. At the heart of its functionality is a meticulously crafted porous solid electrolyte layer. Dr. Haotian Wang, a leading chemical and biomolecular engineer at Rice University and the study's corresponding author, describes this research as a major milestone in atmospheric carbon capture technology.

"We're turning the tide on carbon capture by making it not only more efficient but also more cost-effective across various industries," said Wang. The reactor has demonstrated the ability to regenerate carbon dioxide from carbon-rich solutions at rates applicable to industrial needs, marking a significant leap toward holistic carbon management.

A standout feature of this technology is its versatility. "One of the major advantages is its ability to adapt to various chemical processes while also producing hydrogen concurrently," Wang elaborated. This capacity for hydrogen coproduction could lead to substantial reductions in both capital and operational costs, especially in the downstream manufacturing of sustainable fuels and chemicals.

Traditionally, DAC methods have relied on high temperatures to extract carbon dioxide, often through processes that require complex gas and liquid interactions. This new reactor paradigm, however, toggles the use of high energy temperatures, opting instead for electrical energy to achieve CO₂ extraction at room temperature. This not only streamlines the process but also eliminates the need for additional chemicals and unwanted byproducts.

Rice postdoctoral researcher and co-author Zhiwei Fang emphasized that, "Our approach is leaning towards an electrical energy pathway, which offers numerous advantages, including efficiency and reduced environmental impact." This method also allows the reactor to sidestep the drawbacks associated with conventional amine-based sorbents, like toxicity and instability.

Wang explained that their reactor can effectively separate carbonate solutions, producing a high-purity carbon dioxide in one chamber while generating alkaline absorbents in another. "We’ve optimized the electrical processes to enhance control over ion movement and mass transfer, ultimately diminishing energy demands."

Looking ahead, Dr. Wang hopes this research will inspire further industrial engagement with sustainable practices, propelling initiatives towards a net-zero emissions future. "Rice University is at the forefront of sustainable energy innovation," he proclaimed.

This development is a hopeful sign for environmental advocates and industries alike, indicating that cleaner, more efficient carbon capture solutions are on the horizon. The potential to combine carbon capture with green hydrogen production may usher in a new era of sustainability and efficiency, crucial for combating the impending climate crisis.

Stay tuned as researchers continue to innovate and refine these technologies, paving the way for a cleaner, more sustainable world!

Brasil (PT)

Brasil (PT)

Canada (EN)

Canada (EN)

Chile (ES)

Chile (ES)

España (ES)

España (ES)

France (FR)

France (FR)

Hong Kong (EN)

Hong Kong (EN)

Italia (IT)

Italia (IT)

日本 (JA)

日本 (JA)

Magyarország (HU)

Magyarország (HU)

Norge (NO)

Norge (NO)

Polska (PL)

Polska (PL)

Schweiz (DE)

Schweiz (DE)

Singapore (EN)

Singapore (EN)

Sverige (SV)

Sverige (SV)

Suomi (FI)

Suomi (FI)

Türkiye (TR)

Türkiye (TR)