Unlocking the Secrets of Syngas Production: Metal and Oxide Team Up to Transform Methane

2025-09-01

Author: Yu

In the quest for cleaner energy solutions, the production of synthesis gas—or "syngas"—has gained remarkable importance. Comprising a mixture of hydrogen (H2) and carbon monoxide (CO), syngas is essential for a multitude of industrial applications. While the conventional method of steam reforming has been the go-to technique, researchers are now exploring a more energy-efficient alternative: generating syngas directly from methane (CH4) and oxygen.

One of the primary challenges in this process is to prevent methane from undergoing total oxidation, which would lead to unwanted carbon dioxide (CO2) and water (H2O). This has spurred intense global research focused on optimizing syngas production.

A Game-Changer in Catalysis Research

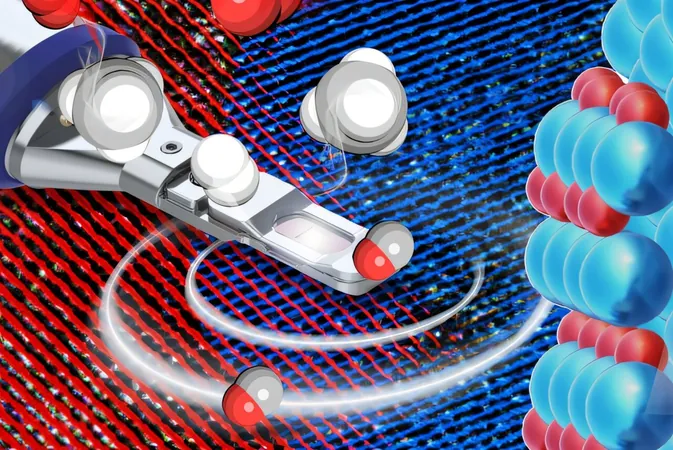

Palladium-based catalysts have emerged as key players in this field. However, the exact mechanics of how palladium facilitates the conversion of methane into syngas have remained a mystery—until now. A groundbreaking collaboration between TU Wien and the National University of Singapore (NUS) has unveiled new insights into this catalytic process using advanced operando transmission electron microscopy.

Real-Time Observation Breakthrough

Published in the prestigious journal Advanced Science, this study introduced high-resolution imaging that captured the intricate dance of palladium nanoparticles during the methane conversion process. By combining these observations with computational simulations, the team was able to illuminate the synergistic interaction between different catalyst regions.

The Dual Role of Catalysts

Professor Günther Rupprechter from TU Wien explains, "Methane is not just an energy source; it fuels chemical production. Even as we strive for sustainability, methane's role in generating syngas remains relevant for the foreseeable future." Thus, the hunt for efficient methods to transform methane into syngas while avoiding over-oxidation—a critical process called partial oxidation of methane (POM)—is crucial.

The research focused on palladium nanoparticles to explore whether it was the metal itself or the palladium oxide formed during the reaction that took the lead in catalysis.

Pioneering Methodology Unveiled

Utilizing a cutting-edge microreactor within the electron microscope allowed for unprecedented real-time analysis. By measuring the products formed throughout the reaction using mass spectrometry alongside their observations, the researchers constructed a refined understanding of the reaction's mechanics.

Combining Forces for Maximum Efficiency

The collaboration has yielded exciting findings: neither palladium nor palladium oxide alone is the hero of the story; instead, their combined efforts create the most effective catalytic reaction. Rupprechter elaborates, "The palladium component dehydrogenates methane into carbon and hydrogen, while the palladium oxide further oxidizes the carbon to carbon monoxide—achieving optimal catalysis at their interface."

Thus, this groundbreaking research not only broadens the horizons for syngas production but also reinforces the potential of advanced nanomaterials in tackling modern energy challenges. As the world pushes toward sustainable energy solutions, understanding these intricate catalytic processes will be vital.

Brasil (PT)

Brasil (PT)

Canada (EN)

Canada (EN)

Chile (ES)

Chile (ES)

Česko (CS)

Česko (CS)

대한민국 (KO)

대한민국 (KO)

España (ES)

España (ES)

France (FR)

France (FR)

Hong Kong (EN)

Hong Kong (EN)

Italia (IT)

Italia (IT)

日本 (JA)

日本 (JA)

Magyarország (HU)

Magyarország (HU)

Norge (NO)

Norge (NO)

Polska (PL)

Polska (PL)

Schweiz (DE)

Schweiz (DE)

Singapore (EN)

Singapore (EN)

Sverige (SV)

Sverige (SV)

Suomi (FI)

Suomi (FI)

Türkiye (TR)

Türkiye (TR)

الإمارات العربية المتحدة (AR)

الإمارات العربية المتحدة (AR)