Unlocking the Secrets of Polyethylene: From Functionalization to Innovative Antibacterial Applications

2024-11-09

Author: Wei

Introduction

Polyethylene (PE), celebrated for its cost-effectiveness, lightweight nature, and versatility, ranks among the most extensively used plastics worldwide. Its utility spans a vast array of uses—from packaging materials that shield our products to structural components that support various industries. However, despite its commonality, PE's widespread application faces a formidable barrier: its chemical inertness limits its functionality, stifling the potential for richer, more innovative uses in sophisticated markets.

The Need for Functionalization

To fully realize the capabilities of PE, researchers are turning their sights to introducing polar functional groups that can enhance its properties and enable a multitude of new applications. This search for effective functionalization methods has become a hot topic within polymer chemistry, as scientists seek to overcome the challenges that PE’s resistance poses to transformation.

Challenges in Modifying Polyethylene

One significant hurdle in modifying PE lies in its tough molecular nature, which renders conventional functionalization approaches largely inefficient. This resistance also aggravates the growing issue of plastic waste, with a considerable amount of PE ending up in landfills. As the threat of plastic pollution looms larger, the urgency to recycle or upcycle PE into valuable materials has never been more pressing.

Emerging Methods in Functionalization

While several strategies exist for altering PE’s structure, many struggle with scalability or efficiency, highlighting an essential need for groundbreaking solutions that skillfully balance environmental impact with the functional enhancements desired in this ubiquitous plastic.

Amination as a Promising Approach

Among the promising methods emerging, amination stands out due to its capacity to introduce nitrogen-containing functional groups to PE. These amines can dramatically increase the polymer's chemical reactivity and improve its performance across diverse applications—from adhesives to surface coatings.

Challenges of Amination

However, efficient amination of PE has yet to be achieved, primarily due to the challenges posed by energy-intensive processes that risk deteriorating the polymer itself. This gap in research has spurred interest in developing more effective, scalable methods.

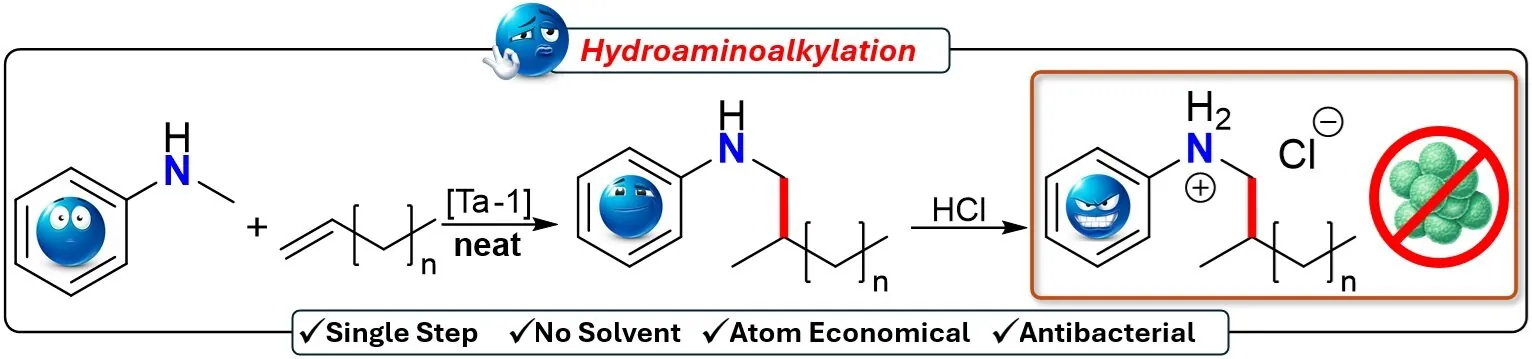

Novel Catalytic Process

My work as a postdoctoral fellow in the Schafer group at the University of British Columbia targets this issue head-on through a novel catalytic process known as hydroaminoalkylation. Previously deployed in the modification of polypropylene, this technique has proved effective for PE, allowing for efficient amination in a straightforward, one-step reaction.

Publication of Results

The results of this exciting process were published in the prestigious journal *Angewandte Chemie International Edition*. This method is particularly remarkable because it operates under mild, solvent-free conditions while avoiding the radical-induced degradation commonly seen with traditional techniques. By applying this innovative approach to vinyl-terminated polyethylene (VTPE), provided by my industrial partner NOVA Chemicals, we achieved amine-functionalized PE with minimal steps, fostering scalability and cost-effectiveness.

Mechanical and Rheological Analysis

Colleagues from the Hatzikiriakos group at UBC conducted a series of tests to analyze the mechanical and rheological properties of the modified PE. Their findings revealed that incorporating amine groups not only altered the chemical properties of the polymer but also enhanced its physical characteristics, including increased crystallization temperature and heightened hydrophilicity due to the formation of hydrogen bonds with water.

Implications for Sustainability

This breakthrough has profound implications for sustainability; our new approach to aminating wasted PE can facilitate upcycling practices, enabling the repurposing of this abundant material in a host of applications.

Exploring Antibacterial Properties

But this is not just about recycling—imagine a world in which high-touch surfaces do not require constant disinfection. This vision became the focus of my study, as I endeavored to explore the potential antibacterial properties of aminated PE. By converting the amine groups into positively charged ammonium groups through treatment with hydrochloric acid, I discovered a mechanism whereby these polymers could attract and disrupt negatively charged bacterial membranes.

Collaboration and Results

Collaborating with the Heyne team at the University of Calgary, we tested the modified polymer against Staphylococcus aureus—a notorious pathogen. The results were astounding; the modified polymer effectively eliminated the bacteria in a remarkably short exposure time.

Future Outlook

This advancement heralds the development of an antibacterial polymer that could potentially serve as a coating for surfaces we interact with daily, providing a new layer of defense against the transmission of harmful germs without necessitating incessant sanitizing.

Conclusion

As we inch closer to a more sustainable and hygienic future, my research stands as a testament to the possibilities inherent in turning a widely-used yet environmentally problematic plastic into a multifunctional material that could revolutionize applications in both everyday life and specialized fields.

Stay Tuned

Stay tuned for more breakthroughs in sustainable materials science as researchers continue to push the boundaries of what is possible!

Brasil (PT)

Brasil (PT)

Canada (EN)

Canada (EN)

Chile (ES)

Chile (ES)

España (ES)

España (ES)

France (FR)

France (FR)

Hong Kong (EN)

Hong Kong (EN)

Italia (IT)

Italia (IT)

日本 (JA)

日本 (JA)

Magyarország (HU)

Magyarország (HU)

Norge (NO)

Norge (NO)

Polska (PL)

Polska (PL)

Schweiz (DE)

Schweiz (DE)

Singapore (EN)

Singapore (EN)

Sverige (SV)

Sverige (SV)

Suomi (FI)

Suomi (FI)

Türkiye (TR)

Türkiye (TR)