Revolutionizing Waste: New Nanofiltration System Turns Cattle Manure into Industrial Gold!

2025-03-28

Author: Jia

Introduction

A groundbreaking collaboration between chemical engineers and animal scientists at the University of Illinois Urbana-Champaign is making waves in the field of sustainability. They have developed an innovative nanofiltration system that successfully extracts valuable industrial chemicals from cattle manure, taking a giant leap toward a circular economy and environmental conservation.

The Problem with Traditional VFA Production

This cutting-edge system targets volatile fatty acids (VFAs) — organic compounds that play a crucial role in the manufacture of fine chemicals. These compounds are essential in a variety of products, ranging from cosmetics to pharmaceuticals. Previously, the process of producing VFAs heavily relied on carbon-intensive methods involving petrochemical feedstocks.

However, with the advent of microbial anaerobic digestion, which employs microorganisms to decompose organic waste, a more energy-efficient solution was at hand — until now, a major hurdle remained: the effective retrieval of VFAs from complex mixtures.

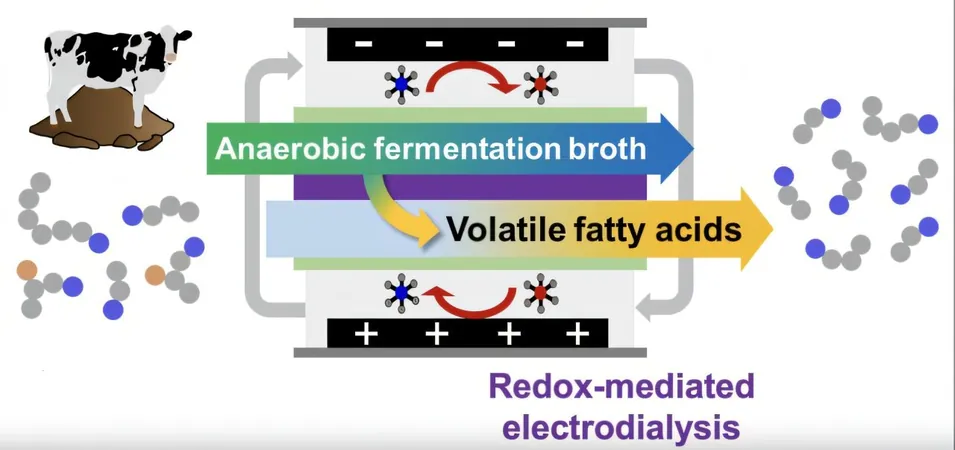

Innovative Electrochemical Separation

The Illinois research team, led by postdoctoral researcher Wangsuk Oh and chemical engineering professor Xiao Su, harnessed an electrochemical separation technique known as redox-mediated electrodialysis. This method incorporates selective ion-exchange membranes, boosting energy efficiency by an impressive 80% compared to standard electrochemical processes.

"Transforming something as seemingly insignificant as manure into industrially relevant chemicals is remarkable," Su expressed. "We’re moving closer to a future where waste can be transformed into valuable resources, enhancing overall chemical production sustainability."

Real-Time Adjustments for Optimal Extraction

The integration of redox molecules enhances the operation of this method by allowing for real-time adjustments in electrical structures, enabling the differentiation of VFAs based on their chemical structures — a feat that presents a major advantage over conventional ion-exchange membranes, which often cannot discern the valuable VFAs.

Practical Applications and Impact

In a practical application of this technology, Su's team collaborated with animal sciences professor Roderick Ian Mackie to ferment cattle manure, then expertly separated the various VFAs. "This novel technique not only addresses the pollution issue from concentrated animal farming but also transforms waste into high-demand chemicals," Mackie noted.

Advantages of the Nanofiltration System

Another significant advantage of this nanofiltration system is its reliance on electrical energy rather than chemicals for separation, leading to drastically reduced chemical waste generation. This opens the door to implementing the technology in industrial settings, paving the way for a more sustainable future in chemical production.

Looking to the Future

Looking ahead, Su and his team are focused on refining the technology and scaling it for broader use. "Our next steps include enhancing the selectivity of membranes, which could lower costs and energy expenses even further, making this innovation not just a win for the environment but also for the economy," he added.

Conclusion

As the world shifts toward greener alternatives, this groundbreaking technology holds the potential to revolutionize how industries view waste, transforming what is traditionally seen as a burden into a treasure trove of valuable resources. Keep an eye on this development — it might just change the way we think about waste forever!

Brasil (PT)

Brasil (PT)

Canada (EN)

Canada (EN)

Chile (ES)

Chile (ES)

Česko (CS)

Česko (CS)

대한민국 (KO)

대한민국 (KO)

España (ES)

España (ES)

France (FR)

France (FR)

Hong Kong (EN)

Hong Kong (EN)

Italia (IT)

Italia (IT)

日本 (JA)

日本 (JA)

Magyarország (HU)

Magyarország (HU)

Norge (NO)

Norge (NO)

Polska (PL)

Polska (PL)

Schweiz (DE)

Schweiz (DE)

Singapore (EN)

Singapore (EN)

Sverige (SV)

Sverige (SV)

Suomi (FI)

Suomi (FI)

Türkiye (TR)

Türkiye (TR)

الإمارات العربية المتحدة (AR)

الإمارات العربية المتحدة (AR)