Revolutionizing Battery Manufacturing: PNNL's Breakthrough with Lithium Oxide

2025-05-26

Author: John Tan

A Breakthrough in Battery Technology

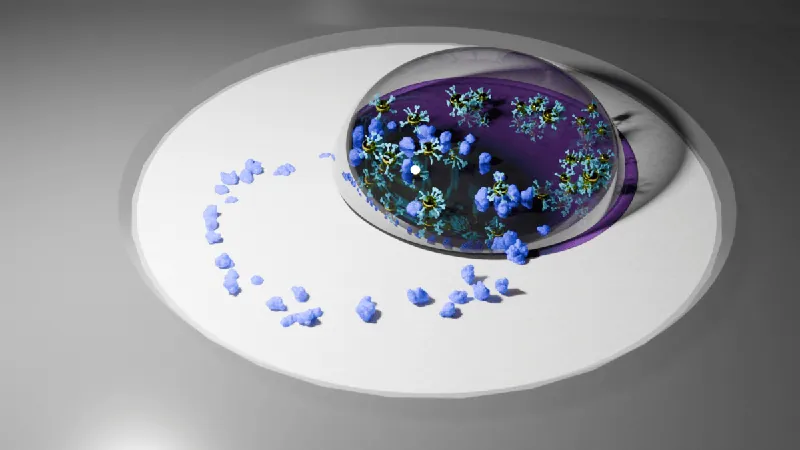

Researchers at the US Department of Energy’s Pacific Northwest National Laboratory (PNNL) have made an exciting discovery that could transform battery manufacturing. By studying the sublimation process of lithium oxide, the team revealed a method to create single-crystal structures in batteries that promise to last longer and be cheaper to produce.

How Sublimation Can Change the Battery Game

In groundbreaking research published in Nature Energy, the PNNL team demonstrated that vapor from sublimated lithium oxide (Li2O) enhances the formation of single crystals when mixed with nickel-rich precursors. Remarkably, this sublimation can occur at standard atmospheric pressure, making it accessible for manufacturing.

Jie Xiao, a leading researcher on the project and a Battelle Fellow, explains that this discovery could lead to faster and more efficient production methods for nickel-rich lithium-ion batteries. 'This work illustrates how advancements in material science can streamline manufacturing,' Xiao stated.

The Challenge with Current Battery Materials

Currently, lithium cathode materials typically form polycrystalline structures, which have weak boundaries that deteriorate over time. These weaknesses can lead to cracks and ultimately diminish battery life.

Xiao elaborated, 'Imagine these tiny particles are clustered together and are stressed as the battery cycles through charging and discharging. This motion can cause cracks that compromise the battery’s integrity.'

The Promise of Single-Crystal Cathodes

Single-crystal cathodes eliminate the vulnerabilities associated with polycrystalline structures, potentially addressing major issues in nickel-rich materials. Xiao remains optimistic, stating, 'We hope these single crystals will solve the significant challenges currently faced in the industry.'

Looking Ahead: Overcoming Cost Barriers

While the research holds tremendous promise, there’s still work to be done before these innovations hit the market. At the moment, the cost of using Li2O is prohibitive for widespread commercial applications. However, Xiao points out that Li2O can be derived from processing more commonly used lithium salts, such as lithium hydroxide (LiOH), providing a path toward feasible production.

Currently, Xiao and her team are collaborating with industry partners to scale up their innovative process while keeping costs manageable. They aim to deliver these advanced single crystals to their partners by 2026, heralding a new era in battery technology.

Brasil (PT)

Brasil (PT)

Canada (EN)

Canada (EN)

Chile (ES)

Chile (ES)

Česko (CS)

Česko (CS)

대한민국 (KO)

대한민국 (KO)

España (ES)

España (ES)

France (FR)

France (FR)

Hong Kong (EN)

Hong Kong (EN)

Italia (IT)

Italia (IT)

日本 (JA)

日本 (JA)

Magyarország (HU)

Magyarország (HU)

Norge (NO)

Norge (NO)

Polska (PL)

Polska (PL)

Schweiz (DE)

Schweiz (DE)

Singapore (EN)

Singapore (EN)

Sverige (SV)

Sverige (SV)

Suomi (FI)

Suomi (FI)

Türkiye (TR)

Türkiye (TR)

الإمارات العربية المتحدة (AR)

الإمارات العربية المتحدة (AR)