Revolutionary New Model Changes the Game in Alloy Design!

2025-05-06

Author: John Tan

Northeastern Scientists Unveil a Groundbreaking Computational Model

In an exciting breakthrough, researchers at Northeastern University have developed a cutting-edge computational model that’s set to transform the way we design alloys. This innovative approach is not only cost-effective but also slashes energy use and offers rapid results!

From Bronze to Science: A New Era in Alloy Design

Alloy creation has come a long way since the days of mixing copper and tin to forge bronze some 5,000 years ago. According to Moneesh Upmanyu, a professor in mechanical and industrial engineering, today's alloy design is a polished science thanks to advancements in our understanding of element properties.

An Editor's Pick for a Reason!

The Journal of Applied Physics has spotlighted Upmanyu's latest research paper, selecting it as an Editor’s Pick, which speaks volumes about its significance in the field.

Speed, Accuracy, and Efficiency: A New Era of Alloy Design!

This model allows for the design of real materials in mere seconds—a stark contrast to traditional methods that involve laborious lab experiments and outdated AI approaches! It provides enhanced speed, accuracy, and cost efficiency.

Mastering Material Defects for Superior Alloys

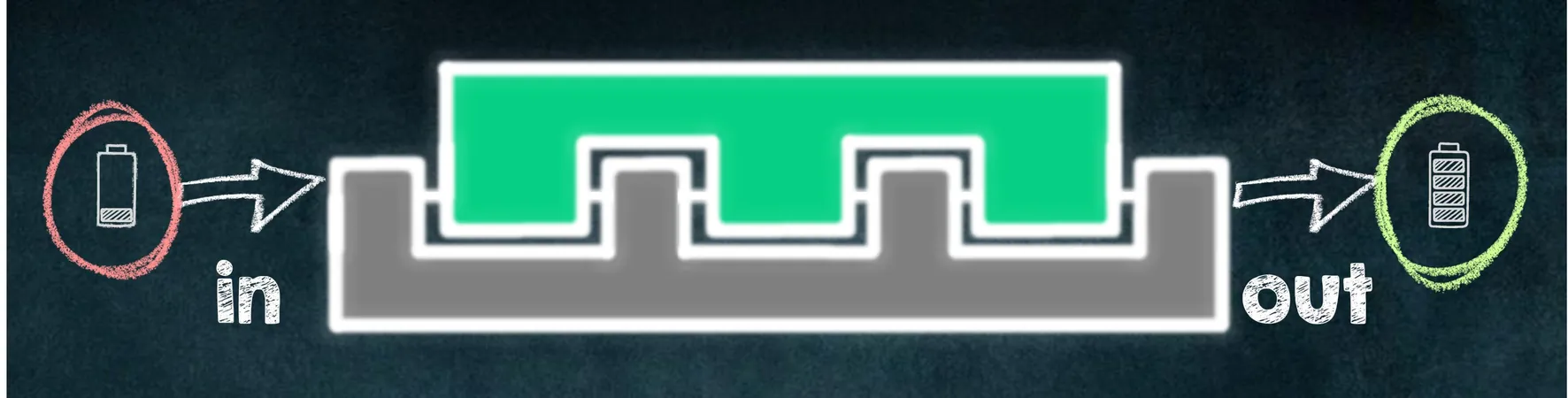

One of the key advancements of this model is its ability to account for material defects—flaws that, while they might seem like inconveniences, can actually enhance properties like strength and corrosion resistance. Unlike many previous computational tools, this model integrates the complexities of real-life crystalline structures.

The Hidden Power of Defects in Materials

A critical focus of Upmanyu’s research is on grain boundaries—imperfections in polycrystalline materials such as copper. "For a crystal small enough to fit between your fingers, the area of grain boundaries can be as large as a basketball court," he explains. This vast space is crucial for determining the behavior of an alloy.

Transforming Alloy Behavior Through Grain Boundary Manipulation

By understanding how solutes behave around these grain boundaries, material engineers can manipulate electrical conduction and other key properties. Current theories often overlook these dynamics, but Upmanyu's model ventures into this uncharted territory.

A Dynamic Perspective on Alloy Formation

The model does not just sit idle; it monitors how solutes gather at grain boundaries and how this affects their motion. Upmanyu describes it as seeing the grain boundaries "dance" under a microscope, a compelling image that hints at the exciting potentials of alloy innovation.

Paving the Way for Future Breakthroughs in Material Science

With this new model, scientists are taking a monumental step toward unlocking how solutes alter the properties of materials at grain boundaries. This pioneering work could pave the way for stronger, more efficient materials, reshaping industries from electronics to aerospace.

Brasil (PT)

Brasil (PT)

Canada (EN)

Canada (EN)

Chile (ES)

Chile (ES)

Česko (CS)

Česko (CS)

대한민국 (KO)

대한민국 (KO)

España (ES)

España (ES)

France (FR)

France (FR)

Hong Kong (EN)

Hong Kong (EN)

Italia (IT)

Italia (IT)

日本 (JA)

日本 (JA)

Magyarország (HU)

Magyarország (HU)

Norge (NO)

Norge (NO)

Polska (PL)

Polska (PL)

Schweiz (DE)

Schweiz (DE)

Singapore (EN)

Singapore (EN)

Sverige (SV)

Sverige (SV)

Suomi (FI)

Suomi (FI)

Türkiye (TR)

Türkiye (TR)

الإمارات العربية المتحدة (AR)

الإمارات العربية المتحدة (AR)