Revolutionary Low-Coherence BOCDR System Breakthrough: A Game-Changer for Strain and Temperature Sensing!

2024-10-01

Overview

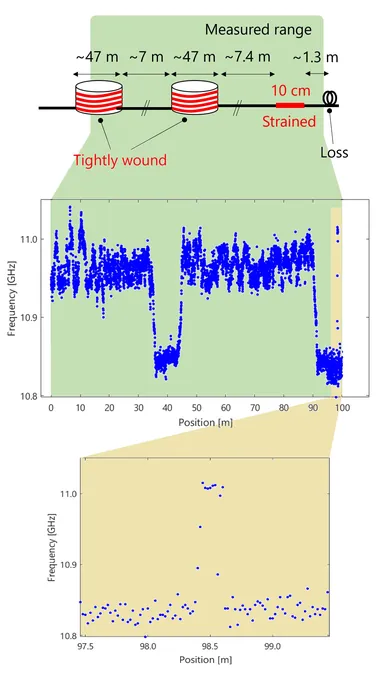

In a groundbreaking achievement, scientists have unveiled an advanced low-coherence Brillouin optical correlation-domain reflectometry (BOCDR) system, effectively tackling longtime obstacles in spatial resolution and measurement range essential for mapping strain and temperature distributions along optical fibers.

Publication

Published in the prestigious Journal of Lightwave Technology, this innovative research aims to revolutionize fiber-optic monitoring—critical in sectors like structural health monitoring, civil engineering, and industrial diagnostics.

Research Leadership

Associate Professor Yosuke Mizuno from Yokohama National University, one of the lead researchers, emphasized the importance of their work. “We addressed the enduring challenge of balancing spatial resolution and measurement range in our original BOCDR technique. Our goal was to create a more efficient system that doesn't rely on complex and cumbersome components like variable delay lines.”

Traditional Challenges

Traditionally, while conventional BOCDR methods provided benefits such as high spatial resolution and the ability to quickly access specific sensing points, they struggled with the trade-off between measurement range and resolution. Previous attempts to find solutions included various special techniques, which, unfortunately, did not fully eliminate this issue.

Innovative Development

The research team, collaborating with NTT Corporation and Dr. Kohei Noda of the University of Tokyo, took a leap forward by developing a low-coherence BOCDR system that utilizes periodic pseudo-random modulation, demonstrating a successful proof-of-concept. This novel approach circumvents the requirement for a variable delay line while maintaining the essential qualities needed for effective strain distribution measurement along optical fibers.

Methodology

Their research utilized a delayed self-homodyne method to analyze the light source's output spectrum, a strategy believed to effectively bridge the gap between measurement range and spatial resolution. In tests, their system exhibited superior accuracy in distributed strain measurement compared to traditional methods—delivering results that were not only more precise but also devoid of systematic errors typically associated with the amplitude modulation-frequency modulation (AM-FM) phase delay.

Technological Innovation

Implementing periodic pseudo-random modulation from an arbitrary waveform generator directly into the light source’s driving current allowed the researchers to modulate its output frequency. This innovation produced multiple correlation peaks, enabling near real-time measurement across the fiber without the disruptive need for variable delay lines.

Significance

Mizuno highlighted the significance of their discovery, stating that “the successful demonstration of our low-coherence BOCDR system not only retains high spatial resolution and extends the measurement range but also simplifies the design of the system, making it practical for real-world applications.”

Future Implications

The implications of their work could reshape the field of optical sensing. With plans for further optimization in spatial resolution and measurement speed, the team is set to refine the technique, making it even more applicable for essential industries.

Vision for the Future

“Ultimately, our vision is for this method to become a standard for precise strain sensing in critical applications like structural health monitoring,” noted Mizuno, setting a clear path for the future of optical fiber technology.

Conclusion

This significant advancement places the research team—comprised of experts from Yokohama National University and NTT Corporation—at the forefront of optical sensor development, with the potential to greatly influence various sectors reliant on accurate fiber-optic measurements. Keep an eye on this revolutionary technology; it could redefine how we understand and monitor structural integrity across industries!

Brasil (PT)

Brasil (PT)

Canada (EN)

Canada (EN)

Chile (ES)

Chile (ES)

España (ES)

España (ES)

France (FR)

France (FR)

Hong Kong (EN)

Hong Kong (EN)

Italia (IT)

Italia (IT)

日本 (JA)

日本 (JA)

Magyarország (HU)

Magyarország (HU)

Norge (NO)

Norge (NO)

Polska (PL)

Polska (PL)

Schweiz (DE)

Schweiz (DE)

Singapore (EN)

Singapore (EN)

Sverige (SV)

Sverige (SV)

Suomi (FI)

Suomi (FI)

Türkiye (TR)

Türkiye (TR)