Revolutionizing Polymer Production: How Carbon Dioxide is Making It Safer and Smarter

2025-05-13

Author: Olivia

From Ice Hockey to Innovative Science

Imagine enjoying a thrilling Cornell ice hockey game, where the action unfolds right before your eyes, all through a remarkable material called methacrylate. Widely used in paints, adhesives, and glass substitutes, methacrylate is about to take on an even more critical role, particularly in the realms of drug delivery. But crafting this sophisticated polymer has traditionally involved a precarious and complex method known as anionic polymerization.

A Game-Changing Discovery

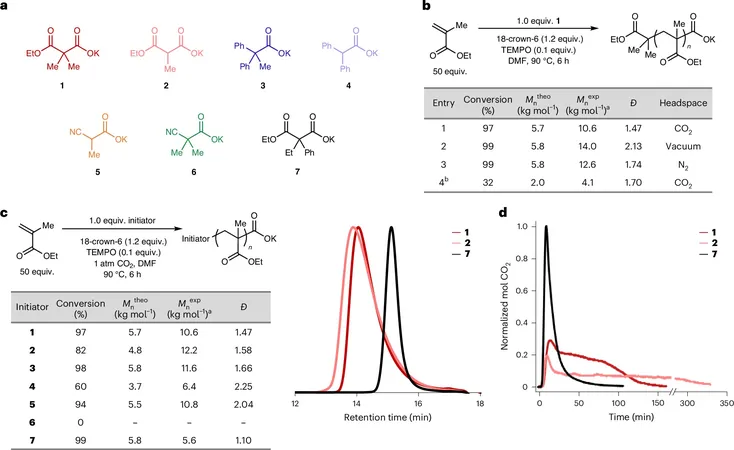

Enter Cornell chemists, who have just unveiled a groundbreaking anionic polymerization process that utilizes carbon dioxide (CO2) for precise control—making it not only user-friendly but scalable! This innovative method is already making waves in diverse fields, aiding engineers in developing metal-free batteries and opening doors for unprecedented biomedical applications.

"By making anionic polymerizations safer and more accessible, we empower the scientific community to create next-generation materials," states Brett Fors, a leading figure in the department and co-author of the study published in *Nature Chemistry.*

The Science Behind the Safety

Anionic polymerization is heralded for its ability to produce materials with exact molecular structures, crucial for specialized applications like drug delivery. As Alexa Easley, a co-author of the study, explains, submitting a proposal to the FDA requires a thoroughly defined polymer structure—something traditional materials like Plexiglas simply can’t provide.

Old Methods vs. New

However, existing anionic polymerization techniques often spell trouble: they involve toxic metals, explosive chemicals, and other hazardous compounds, all while demanding low temperatures and strict environmental controls. In stark contrast, Cornell's novel approach—dubbed CO2-mediated reversible deactivation anionic polymerization (CMAP)—is revolutionary. This method operates simply, using a single container and CO2 in conjunction with an initiator, and requires just moderate heating.

Easley emphasizes the dual roles of carbon dioxide in this process: "CO2 can both start and halt the reaction quickly, while protecting the highly reactive enolate component essential for the method's success."

Real-World Applications and Future Prospects

Despite still needing further development for industry-scale adoption, the CMAP method is already in play. Researcher Easley, during her time as a graduate student at Texas A&M University, faced challenges in polymer development for batteries—until CMAP provided the solution she was searching for. The simplicity of this method holds promise not only for methacrylate materials but possibly for other vinyl monomers as well.

Transforming Research Into Reality

The excitement doesn't stop here. As CMAP continues to evolve, it is set to inspire future reversible strategies in polymer chemistry, potentially reshaping the landscape of material science—making it safer, more efficient, and readily accessible to researchers everywhere.

Cornell's breakthrough truly marks a turning point in the journey of materials science, proving that with a little ingenuity and the right elements, the future of polymer production can be both groundbreaking and safe.

Brasil (PT)

Brasil (PT)

Canada (EN)

Canada (EN)

Chile (ES)

Chile (ES)

Česko (CS)

Česko (CS)

대한민국 (KO)

대한민국 (KO)

España (ES)

España (ES)

France (FR)

France (FR)

Hong Kong (EN)

Hong Kong (EN)

Italia (IT)

Italia (IT)

日本 (JA)

日本 (JA)

Magyarország (HU)

Magyarország (HU)

Norge (NO)

Norge (NO)

Polska (PL)

Polska (PL)

Schweiz (DE)

Schweiz (DE)

Singapore (EN)

Singapore (EN)

Sverige (SV)

Sverige (SV)

Suomi (FI)

Suomi (FI)

Türkiye (TR)

Türkiye (TR)

الإمارات العربية المتحدة (AR)

الإمارات العربية المتحدة (AR)