Revolutionary Technique Enables Real-Time Monitoring of Nuclear Reactor Materials

2025-08-27

Author: Liam

A Breakthrough in Nuclear Safety!

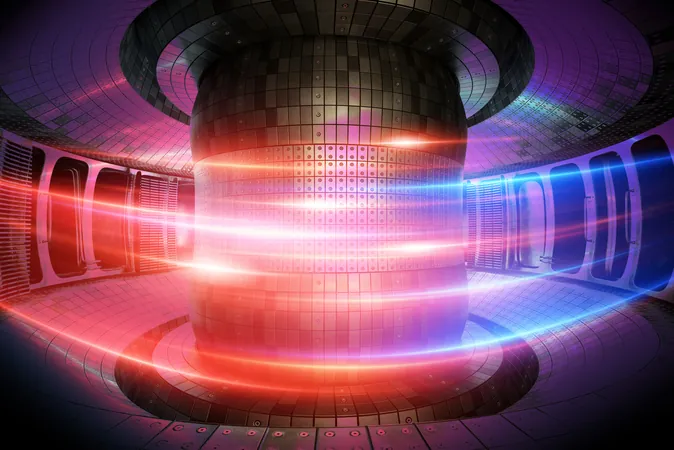

MIT researchers have unveiled a groundbreaking technique for real-time, 3D monitoring of corrosion and cracking in materials inside nuclear reactors. This innovation could pave the way for engineers and scientists to design safer, more efficient reactors that enhance electricity generation and naval propulsion systems.

Harnessing the Power of X-rays

In their experiments, the team utilized powerful X-rays to replicate neutron interactions within reactor materials. They discovered that introducing a silicon dioxide buffer layer between materials and their substrates significantly stabilizes samples, allowing for an unprecedented analysis of material failure in real-time.

Extended Reactor Lifespan and Enhancements in Performance

Ericmoore Jossou, a leading professor at MIT, highlighted the importance of improving reactor materials: "Enhancing material durability means we can extend reactor lifespans and reduce failure rates, maximizing our return on investment in nuclear power."

Innovative Imaging Techniques

For the first time, researchers can observe the gradual failure of materials, capturing critical data that informs the design of stronger, more resilient components that can withstand the intense conditions inside nuclear reactors.

Complex Preparation Unveils New Discoveries

The team's journey to this breakthrough was not without its challenges. Initial attempts at creating nickel samples were thwarted by unintended chemical reactions with the substrate. After multiple trials, they established that a silicon dioxide layer effectively mitigated these issues, leading to stable 3D imaging of materials under stress.

A Dual Purpose Discovery

Interestingly, the researchers found that their X-ray technique could also control strain levels in materials, a discovery that could revolutionize microelectronics manufacturing by enhancing electrical and optical properties through precise deformation.

Future Applications and Implications

Looking ahead, the team aims to apply this technique to more complex alloys used in both nuclear and aerospace applications, while also experimenting with how varying buffer layer thicknesses can further influence strain control.

Significance of the Research

This research not only sheds light on nanoscale materials under radiation but also emphasizes the crucial role substrate properties play in material stability, indicating that the foundation can dictate how materials respond to stress.

Supported by funding from the MIT Faculty Startup Fund and the U.S. Department of Energy, this innovative research is set to transform our understanding and capabilities in the field of nuclear science.

Brasil (PT)

Brasil (PT)

Canada (EN)

Canada (EN)

Chile (ES)

Chile (ES)

Česko (CS)

Česko (CS)

대한민국 (KO)

대한민국 (KO)

España (ES)

España (ES)

France (FR)

France (FR)

Hong Kong (EN)

Hong Kong (EN)

Italia (IT)

Italia (IT)

日本 (JA)

日本 (JA)

Magyarország (HU)

Magyarország (HU)

Norge (NO)

Norge (NO)

Polska (PL)

Polska (PL)

Schweiz (DE)

Schweiz (DE)

Singapore (EN)

Singapore (EN)

Sverige (SV)

Sverige (SV)

Suomi (FI)

Suomi (FI)

Türkiye (TR)

Türkiye (TR)

الإمارات العربية المتحدة (AR)

الإمارات العربية المتحدة (AR)