Revolutionary Customized Face Masks: How University of Guelph Leads the Way in Personal Protection Technology!

2024-12-12

Author: Liam

Introduction

In an innovative breakthrough, researchers at the University of Guelph have developed a cutting-edge method for creating personalized face masks that promise enhanced comfort and effectiveness.

The Process of Custom Mask Creation

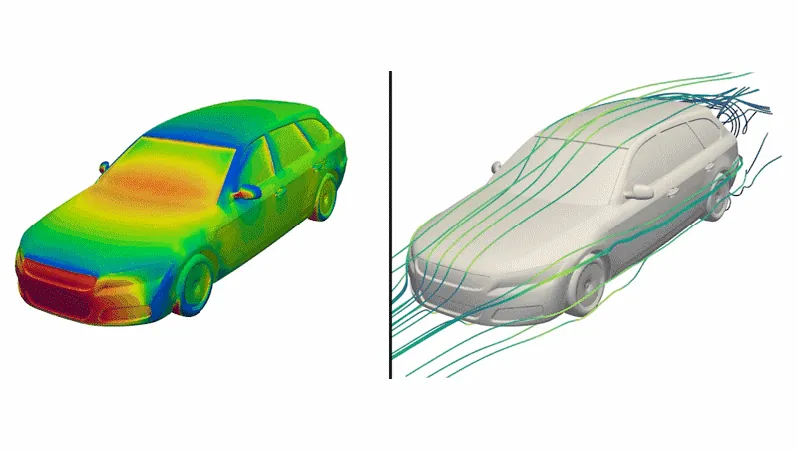

This new approach utilizes a unique video-based technique where individuals capture a quick five-second recording of their face. The brief video allows the software to analyze intricate facial features from various angles and expressions before converting these frames into still images focusing on critical areas like the nose, mouth, and eye distance.

Design and Automation Benefits

This advanced data is then uploaded into specialized design software, where powerful algorithms generate an individualized mask model that matches the wearer’s specific facial contours. This level of customization significantly boosts the mask's overall fit and efficiency.

Director's Insight on Manufacturing Efficiency

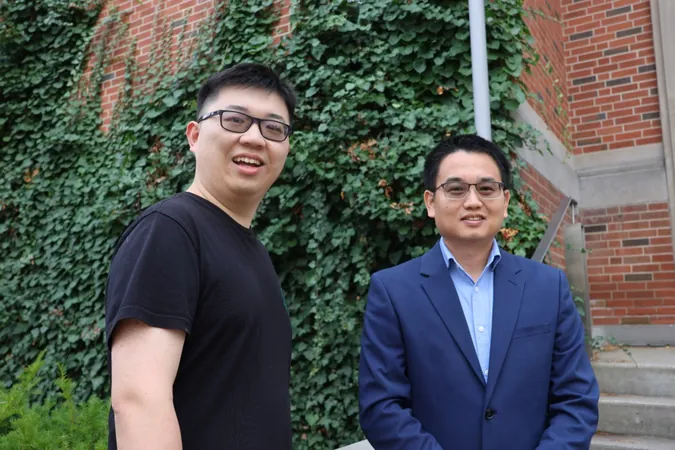

Director of the project, Yang, emphasizes the financial and time-saving benefits of automating the process. "It's a low-cost option compared to traditional manufacturing practices like casting," he explains. By relying on automation and innovative 3D printing technology, they can efficiently produce masks tailored to each user.

User Experience

Participants testing the 3D-printed masks reported a notably comfortable experience. Users were pleasantly surprised by how easily they could move their jaws and make expressions without feeling restricted or discomforted.

Challenges in Material Availability

However, not everything about the project is simple sailing. Yang points out a current limitation: the availability of 3D-printable medical-grade materials. The protection a mask offers hinges on both the material used and the filters incorporated within. “The mask serves as a supportive structure that fits snugly against the face,” he notes. “Meanwhile, the actual filtration part is placed on top and is mass-produced, which falls outside the direct design phase.”

Future Applications and Potential

Beyond the realm of personal protective equipment (PPE), this technology opens doors to diverse applications. Yang highlights, “This kind of knowledge can be leveraged in various sectors in the future.” For instance, he has already been approached by medical professionals interested in adapting the technology for customized respirators for sleep apnea patients, commonly referred to as Continuous Positive Airway Pressure (CPAP) machines.

Expanding Horizons of Customization

Furthermore, Yang envisions this innovative technology being instrumental in manufacturing a wide range of products beyond masks. Customized sportswear, helmets, gloves, goggles, shoes, and even dental implants could all see improved designs thanks to this advanced technique. "We genuinely believe this technology has the potential to enhance public health and safety tremendously," adds Yang.

Conclusion

This groundbreaking study has been published in *The International Journal of Advanced Manufacturing Technology* and was made possible through funding from a discovery grant by the National Sciences and Engineering Research Council of Canada.

Stay tuned as the University of Guelph continues to push the boundaries of modern technology, redefining the future of healthcare and personal protective equipment!

Brasil (PT)

Brasil (PT)

Canada (EN)

Canada (EN)

Chile (ES)

Chile (ES)

España (ES)

España (ES)

France (FR)

France (FR)

Hong Kong (EN)

Hong Kong (EN)

Italia (IT)

Italia (IT)

日本 (JA)

日本 (JA)

Magyarország (HU)

Magyarország (HU)

Norge (NO)

Norge (NO)

Polska (PL)

Polska (PL)

Schweiz (DE)

Schweiz (DE)

Singapore (EN)

Singapore (EN)

Sverige (SV)

Sverige (SV)

Suomi (FI)

Suomi (FI)

Türkiye (TR)

Türkiye (TR)