MIT’s Groundbreaking AI-Driven Database of 8,000 EV Designs Is Set to Revolutionize the Future of Electric Vehicles!

2024-12-22

Author: Amelia

In an impressive display of innovation, engineers at the Massachusetts Institute of Technology (MIT) have rolled out an astonishing database featuring over 8,000 electric vehicle (EV) designs that harness the power of artificial intelligence (AI). This extraordinary project, named DrivAerNet++, promises to fast-track the design process for future vehicles, dramatically reshaping the automotive landscape.

The DrivAerNet++ database is an open-source treasure trove of 3D models that capture the essence of today’s most popular car styles while integrating critical information about their aerodynamic performance. This initiative not only caters to the evolving demands of consumers but is also pivotal in a world increasingly focused on sustainability.

Electric cars, which have been around for over a century, are witnessing a spectacular rise in popularity as part of a global shift towards greener transportation. Traditionally, crafting a new EV can span several years due to the complexity and resource demands of the design and prototyping phases. Nevertheless, the introduction of this extensive database aims to streamline and expedite the entire process.

While current industry practices are often bogged down by proprietary specifications and sluggish testing protocols, the open nature of the DrivAerNet++ database provides a much-needed alternative. By combining this digital library with AI models, manufacturers could witness a surge in innovative car designs, advancing the pace of research and development in the industry.

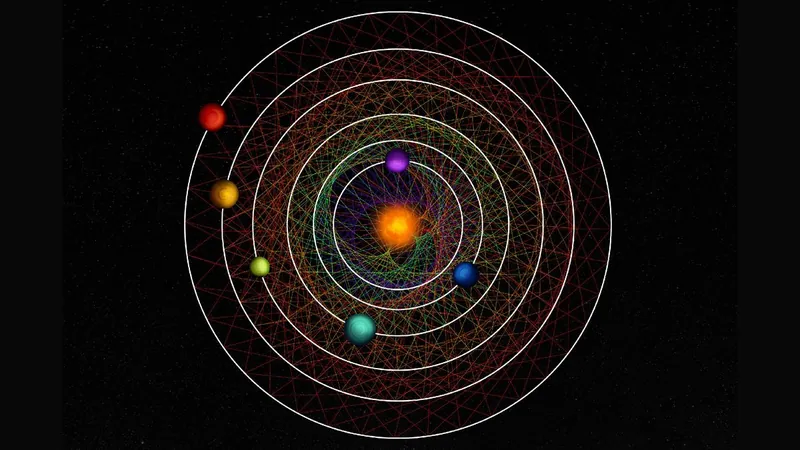

The vast dataset generated by MIT’s research holds 39 terabytes of information and required a staggering 3 million CPU hours to produce, utilizing the institution’s robust computing resources. The technique employed involved an intelligent algorithm that meticulously adjusted 26 design parameters, such as vehicle length and wheel shape, ensuring that each created model could either build on existing designs or produce entirely new concepts.

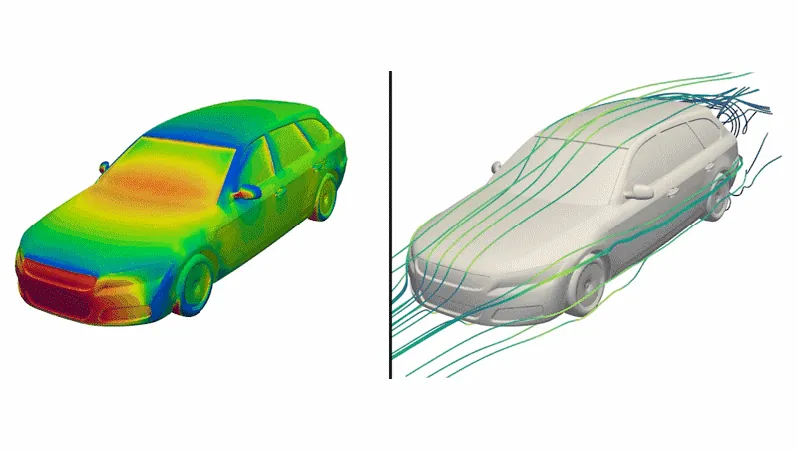

What sets this effort apart is its ability to conduct complex fluid dynamics simulations, effectively predicting how air will behave around each design. Faez Ahmed, an assistant professor of mechanical engineering at MIT, stated, “Traditionally, manufacturers can only make small tweaks due to the time-consuming nature of testing. With larger datasets and the capability to quickly assess design performance, we can leverage machine-learning models to enhance the design process significantly.”

Additionally, Mohamed Elrefaie, a mechanical engineering student at MIT, highlighted the dual benefits of the database: it not only reduces costs in R&D but also accelerates the arrival of efficient transportation solutions that could mitigate climate impacts.

The potential of integrating AI with the provided dataset means that generative models can now output designs in mere seconds rather than hours. This remarkable shift contrasts sharply with earlier AI frameworks that relied on limited datasets, paving the way for more efficient EVs that can be evaluated for efficiency and range without the tedious and costly process of physical prototypes.

Stay tuned as MIT’s innovative approach unfolds — it heralds a future where cutting-edge technology and sustainability drive the evolution of electric vehicles!

Brasil (PT)

Brasil (PT)

Canada (EN)

Canada (EN)

Chile (ES)

Chile (ES)

España (ES)

España (ES)

France (FR)

France (FR)

Hong Kong (EN)

Hong Kong (EN)

Italia (IT)

Italia (IT)

日本 (JA)

日本 (JA)

Magyarország (HU)

Magyarország (HU)

Norge (NO)

Norge (NO)

Polska (PL)

Polska (PL)

Schweiz (DE)

Schweiz (DE)

Singapore (EN)

Singapore (EN)

Sverige (SV)

Sverige (SV)

Suomi (FI)

Suomi (FI)

Türkiye (TR)

Türkiye (TR)