Revolutionary Automated Technique Set to Transform Electronic Chip Production with Graphene

2025-03-26

Author: Olivia

Revolutionary Automated Technique Set to Transform Electronic Chip Production with Graphene

A groundbreaking advancement in graphene transfer technology has been unveiled by a research team led by Delphine Bouilly, a professor at the University of Montreal (UdeM) and director of the Electronic Nanobiosensor Design and Application Research Unit at the Institute for Research in Immunology and Cancer (IRIC). This innovative method, spearheaded by doctoral candidate Amira Bencherif, aims to streamline the large-scale production of electronic chips, especially in the field of molecular diagnostics. The exciting findings have been published in the prestigious journal npj 2D Materials and Applications.

Graphene, a remarkable 2D nanomaterial consisting of a single layer of carbon atoms, is celebrated for its exceptional physical and electronic characteristics, making it an ideal candidate for various technological applications, including advanced biosensors crucial for modern medical diagnostics.

Despite its rapid synthesis in large quantities on copper surfaces, transferring graphene ribbons from these metal bases to production wafers—essential for assembling multiple chips at once—has presented a significant challenge. This step is critical in the manufacturing process of devices utilizing 2D materials like graphene.

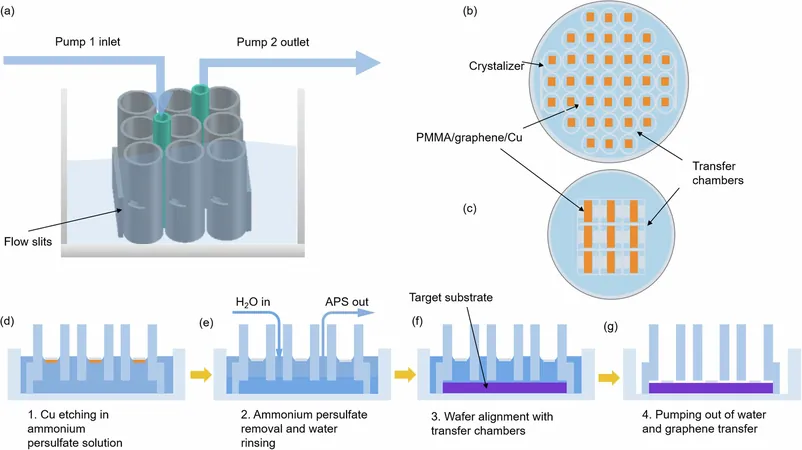

To tackle this challenge, Bouilly’s team has developed a pioneering automated graphene transfer technique. Their setup involves a sophisticated network of glass chambers where graphene-coated copper sheets reside. These chambers utilize a pumping system that alternates between filling and emptying with specific solutions, effectively dissociating the graphene from the copper and transferring it to properly aligned production wafers. This fully automated process mimics a miniature assembly line, eradicating the need for manual intervention.

Unlocking New Manufacturing Potential

The advantages presented by this novel technique are substantial. By automating the previously labor-intensive and dexterity-demanding transfer method, the process becomes not only significantly faster but also far more efficient. The capability of transferring multiple graphene ribbons in parallel is a game-changer, enhancing both speed and production volume. Moreover, the system allows for the vertical assembly of several graphene layers, expanding the potential applications of this versatile material.

The implications of this innovative technology extend beyond just ease of transfer. The automated parallel method minimizes graphene waste, ensuring greater yields during production. This efficiency will be vital as the demand for graphene-based devices—especially in medical diagnostics for diseases such as cancer—continues to rise.

Moreover, as the Bouilly laboratory progresses in its research, the implications of their work could well revolutionize the field of biosensors and beyond, enhancing the way technology interfaces with healthcare diagnostics and providing groundbreaking solutions in the battle against various diseases.

The future looks bright for graphene applications, and thanks to this breakthrough, the ambition of integrating sophisticated electronics into everyday life is one step closer to reality. Stay tuned for more updates on this transformative technology that promises to change the landscape of electronic chip production forever!

Brasil (PT)

Brasil (PT)

Canada (EN)

Canada (EN)

Chile (ES)

Chile (ES)

Česko (CS)

Česko (CS)

대한민국 (KO)

대한민국 (KO)

España (ES)

España (ES)

France (FR)

France (FR)

Hong Kong (EN)

Hong Kong (EN)

Italia (IT)

Italia (IT)

日本 (JA)

日本 (JA)

Magyarország (HU)

Magyarország (HU)

Norge (NO)

Norge (NO)

Polska (PL)

Polska (PL)

Schweiz (DE)

Schweiz (DE)

Singapore (EN)

Singapore (EN)

Sverige (SV)

Sverige (SV)

Suomi (FI)

Suomi (FI)

Türkiye (TR)

Türkiye (TR)

الإمارات العربية المتحدة (AR)

الإمارات العربية المتحدة (AR)