Groundbreaking Polymers Set for Extreme Testing on the International Space Station!

2024-11-08

Author: Jacques

Groundbreaking Polymers Set for Extreme Testing on the International Space Station!

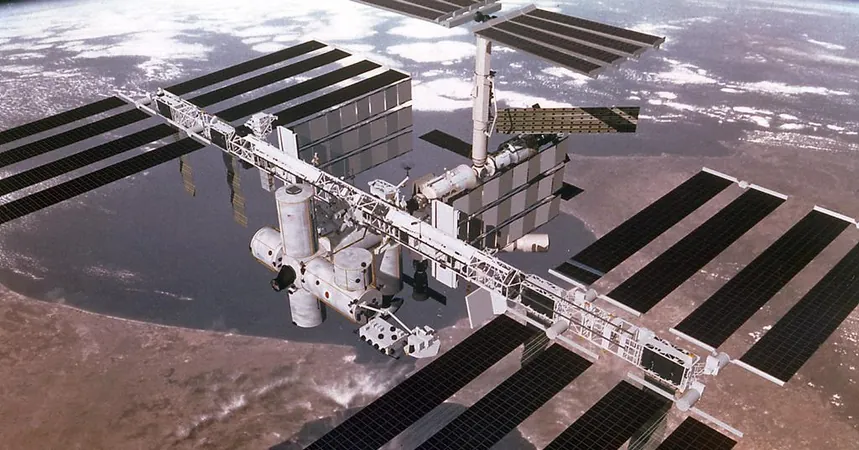

In an exciting development for space exploration, researchers from the University of Bristol are preparing to test four innovative polymers aboard the International Space Station (ISS). These cutting-edge materials, designed to withstand the harshest conditions of space, could revolutionize the longevity and efficiency of spacecraft components.

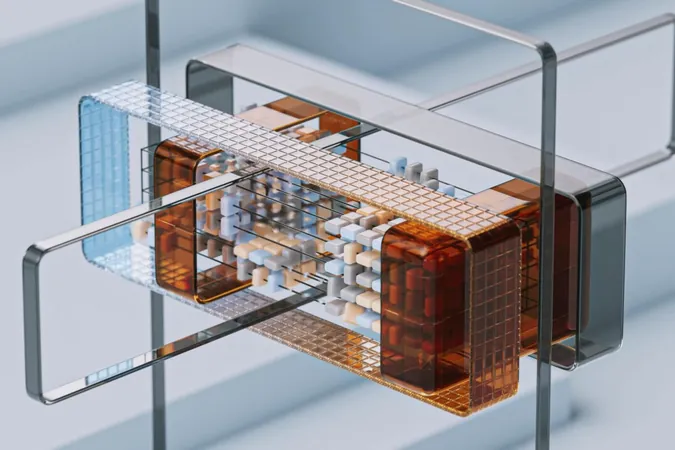

Two of the polymers incorporate advanced nanoparticles, while all four have been reinforced with carbon fibers, creating a robust structure that promises to endure the rigorous demands of space travel. The ultimate goal? To enable spacecraft to journey further into the cosmos and spend extended periods working and exploring beyond our planet. Remarkably, these materials have been engineered for sustainability; when they reach the end of their useful life, they can be recycled instead of contributing to space junk.

Launched aboard a SpaceX rocket, these polymers are now safely positioned on the Bartolomeo platform at the front of the ISS. They will circle the Earth up to 9,000 times over the course of the next 12 to 18 months, undergoing tests that will expose them to extreme temperatures ranging from -150°C to 120°C. Additionally, they must resist space debris hurtling towards them at speeds seven times faster than a speeding bullet, alongside intense electromagnetic radiation and corrosive atomic oxygen in a high vacuum environment.

Ian Hamerton, a researcher at the Bristol Composites Institute specializing in polymers and sustainable composites, stated that space represents “the most challenging” environment for material innovation. The arrival of these polymers at the ISS marks a significant milestone following five years of dedicated work by Hamerton’s team. He emphasized the gravity of the challenge: "We are putting our materials expertise against the most extreme conditions imaginable—temperature fluctuations, mechanical stress, radiation exposure, and high-velocity impacts. Repairing these materials in space is nearly impossible, so they must be built to endure."

This pioneering project not only reflects groundbreaking research but also offers invaluable experience for early career researchers, postgraduates, and Aerospace Engineering undergraduates involved at the University of Bristol. Many of these students have contributed their final year research projects to the space materials initiative, preparing the next generation of scientists and engineers for the future of space exploration.

As we await the results of these daring tests, the potential benefits for future missions could be monumental, paving the way for more sustainable and resilient structures in outer space. Will these polymers withstand the brutal challenges of the final frontier? Stay tuned as we follow this extraordinary journey into the unknown!

Brasil (PT)

Brasil (PT)

Canada (EN)

Canada (EN)

Chile (ES)

Chile (ES)

España (ES)

España (ES)

France (FR)

France (FR)

Hong Kong (EN)

Hong Kong (EN)

Italia (IT)

Italia (IT)

日本 (JA)

日本 (JA)

Magyarország (HU)

Magyarország (HU)

Norge (NO)

Norge (NO)

Polska (PL)

Polska (PL)

Schweiz (DE)

Schweiz (DE)

Singapore (EN)

Singapore (EN)

Sverige (SV)

Sverige (SV)

Suomi (FI)

Suomi (FI)

Türkiye (TR)

Türkiye (TR)