Unleashing Toughness: Nature-Inspired Polymer Innovations Point to Stronger Materials

2024-09-18

Introduction

In the quest for stronger and more resilient materials, scientists have turned to nature for inspiration. Biological systems, renowned for their ability to design strong yet flexible structures, offer crucial insights. A prime example is the sea sponge, which develops in layers, integrating minerals with softer areas. This unique architecture strikes the perfect balance between strength and flexibility, providing a blueprint for materials scientists.

Nature's Methods

Nancy Sottos, a leading researcher at the Beckman Institute for Advanced Science and Technology and a distinguished chair in the Department of Materials Science and Engineering at the University of Illinois Urbana-Champaign, emphasized the potential of nature’s methods. She stated, "Nature has a way of turning brittle materials into tough ones through intricate patterning." Biological patterns often consist of both stiff and soft regions, which enable them to endure significant strains and maintain high levels of strength.

Breakthrough Study

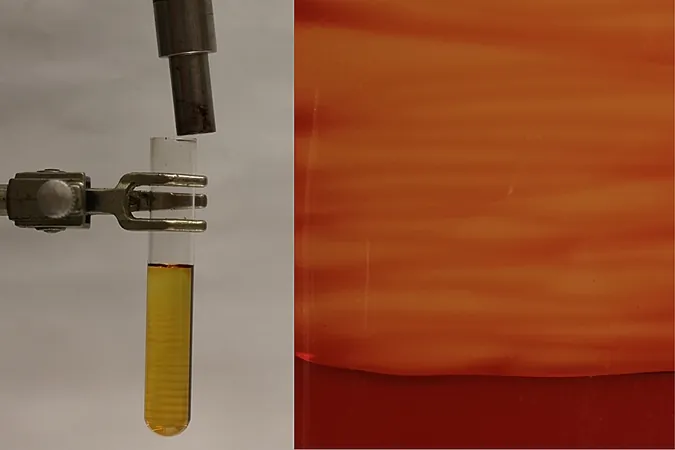

A groundbreaking study recently published in *Nature* showcases how Sottos and her team harnessed frontal polymerization—a heat-induced chemical reaction process—to mimic this natural patterning. Building on a 2021 study that established frontal polymerization as a reliable technique for producing biologically inspired polymers, the researchers have now developed a novel approach that allows for the controlled formation of crystalline patterns within these materials.

Innovative Manufacturing Techniques

"This research opens up a new frontier in materials science—patterning materials without molds or milling, achieving unique properties through this innovative structure," explained Jeff Moore, a researcher at the Beckman Institute and professor emeritus of chemistry at Illinois. Notably, he played a crucial role in refining the chemical formulations that made these findings possible.

Morphogenic Manufacturing

The team employed morphogenic manufacturing techniques, making minor adjustments to the chemical reactions to produce the desired crystalline patterns. Lead author Justine Paul shared the excitement of the process, stating, "Determining the optimal reaction conditions was a detailed journey, but witnessing the incredible results in the patterned microstructure was immensely satisfying."

Material Properties

The resulting material features a combination of amorphous (unstructured) and crystalline regions, fostering exceptional resilience. The contrast between flexible and extremely rigid regions contributes significantly to the durability of the products. This unique control over polymer architecture would not have been achieved without the collaborative efforts across various disciplines at the Beckman Institute.

Interdisciplinary Collaboration

Cecilia Leal, a professor of materials science and engineering, utilized X-ray scattering techniques to investigate how polymer chains align within the patterned materials, shedding light on the intricate structure-property relationships. Meanwhile, aerospace engineering professor Philippe Geubelle concentrated on modeling the manufacturing process, particularly focusing on the thermo-chemical instabilities that pave the way for producing these unique heterogeneous materials.

Conclusion

The successful outcomes of this project underscore the importance of interdisciplinary collaboration, bridging mechanics, materials science, and chemistry. Sottos, Moore, Leal, and Geubelle’s teamwork within the Autonomous Materials Systems Working Group at Beckman Institute exemplifies the power of a diverse scientific environment. As we unlock the secrets of nature to improve synthetic materials, the implications stretch far beyond academia. Industries such as aerospace, automotive, and biomedical engineering stand to benefit greatly from these advancements, with stronger, more resilient products on the horizon. The future of material science is indeed promising, and it's clear: by looking to nature, we can overcome the limitations of current technology and engineer a better tomorrow.

Brasil (PT)

Brasil (PT)

Canada (EN)

Canada (EN)

Chile (ES)

Chile (ES)

España (ES)

España (ES)

France (FR)

France (FR)

Hong Kong (EN)

Hong Kong (EN)

Italia (IT)

Italia (IT)

日本 (JA)

日本 (JA)

Magyarország (HU)

Magyarország (HU)

Norge (NO)

Norge (NO)

Polska (PL)

Polska (PL)

Schweiz (DE)

Schweiz (DE)

Singapore (EN)

Singapore (EN)

Sverige (SV)

Sverige (SV)

Suomi (FI)

Suomi (FI)

Türkiye (TR)

Türkiye (TR)