Unleashing Martian Metal: Scientists Develop Groundbreaking Method to Extract Resources from Mars

2025-08-26

Author: Arjun

Building a New Home on Mars

As dreams of colonizing Mars captivate billionaires, space agencies, and cosmic enthusiasts alike, a giant question looms: How do we secure the materials necessary for construction? Shipping them from Earth isn't feasible; NASA's Perseverance Rover alone cost $243 million to send to the Red Planet, and that's just one ton!

Harnessing Martian Resources

Enter Dr. Deddy Nababan, a CSIRO Postdoctoral Fellow and Swinburne alum, who has dedicated years to solving this dilemma. His innovative approach centers around utilizing Martian regolith, the planet's soil, to create metals on-site—an idea known as in-situ resource utilization (ISRU). Dr. Nababan asserts, "Transporting tons of metals to Mars might be possible, but it's anything but economical. Instead, we can manufacture metals directly from Martian resources."

Astrometallurgy: Making Metal in Space

Teaming up with Professor Akbar Rhamdhani from Swinburne University, Dr. Nababan is delving into astrometallurgy, the science of producing metals in space. Mars holds the key materials needed to do this, including iron-rich oxides in regolith and carbon from the thin atmosphere acting as a reducing agent. Together, they tested this metal-extraction process using a simulant that mimics the soil found on Mars, producing intriguing results. Their findings, which hailed from experiments conducted under simulated Martian conditions, were published in the journal Acta Astronautica.

From Simulation to Reality

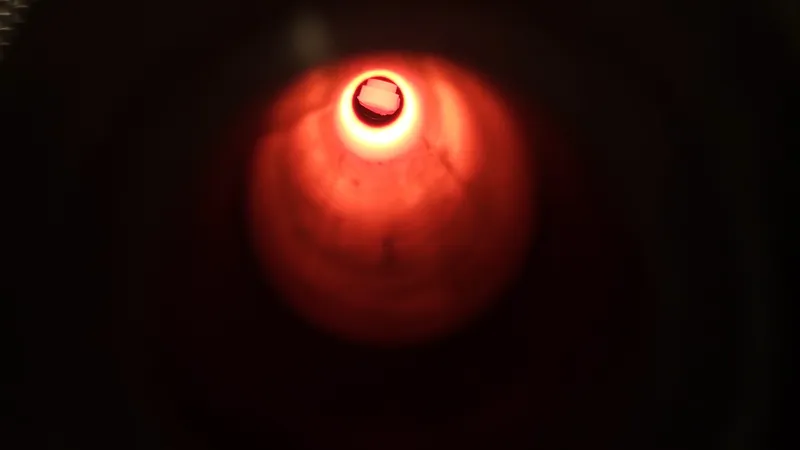

In their experiments, they heated the simulant to simulative Martian grades, revealing that pure iron could form at around 1,000°C, with iron-silicon alloys emerging at an impressive 1,400°C. Professor Rhamdhani noted, "At these temperatures, all metals merged into a single droplet, which could then be collected just like it is on Earth."

Zero Waste Metallurgy

Looking toward a sustainable future, Dr. Nababan and Professor Rhamdhani are dedicated to perfecting a zero-waste process. They aim to ensure that byproducts from metal production can be repurposed into useful items, making the entire operation more efficient.

A New Age of Space Science

With every launch carrying immense cost, ISRU is becoming increasingly critical in space science. The recent success of the MOXIE experiment on the Perseverance rover, which produced breathable oxygen from Martian carbon dioxide, highlights advances in this field. Now, metal production is poised to be the next milestone.

The Future of Martian Manufacturing

Professor Rhamdhani envisions using Mars-made alloys for constructing habitats and machinery to support excavation. However, significant challenges remain in ensuring that these materials hold up over time and can be replicated on the actual Martian surface.

Global Interest and Collaborative Efforts

To bolster this revolutionary field, Professor Rhamdhani and his team recently hosted a four-day workshop in South Korea focusing on astrometallurgy. The response has been highly encouraging, indicating a surge in global interest as humanity turns its gaze toward Mars.

Beyond Space Exploration

For Dr. Nababan, the implications of their research extend beyond extraterrestrial boundaries. He hopes to refine metallurgy techniques on Earth through their findings, demonstrating a commitment to advancing both space exploration and terrestrial industry.

"In pursuing this research, I aspire to contribute to humanity's progress in space, ultimately benefiting life here on Earth as well," he reflects.

Brasil (PT)

Brasil (PT)

Canada (EN)

Canada (EN)

Chile (ES)

Chile (ES)

Česko (CS)

Česko (CS)

대한민국 (KO)

대한민국 (KO)

España (ES)

España (ES)

France (FR)

France (FR)

Hong Kong (EN)

Hong Kong (EN)

Italia (IT)

Italia (IT)

日本 (JA)

日本 (JA)

Magyarország (HU)

Magyarország (HU)

Norge (NO)

Norge (NO)

Polska (PL)

Polska (PL)

Schweiz (DE)

Schweiz (DE)

Singapore (EN)

Singapore (EN)

Sverige (SV)

Sverige (SV)

Suomi (FI)

Suomi (FI)

Türkiye (TR)

Türkiye (TR)

الإمارات العربية المتحدة (AR)

الإمارات العربية المتحدة (AR)