TRS Revolutionizes Crusher Plant Operations with Game-Changing Automation Technology!

2024-10-26

Author: Rajesh

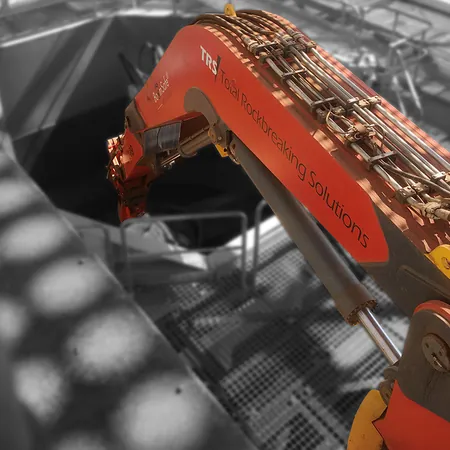

Total Rockbreaking Solutions (TRS) is making waves in the mining industry with the introduction of a revolutionary solution aimed at automating attachment changeovers in crushing plants. This innovative technology promises to drastically reduce downtime, enhance safety, and maximize productivity for mining operators, addressing a critical challenge in heavy machinery operations.

At the heart of this advancement is the TRS BoomSafe® boom control system, meticulously engineered to integrate seamlessly with the SteelWrist fully automatic quick couplers. This synergy allows for complete automation of attachment changes, thereby eliminating the need for manual intervention and significantly speeding up the process.

In crushing plants, time is of the essence. Delays resulting from equipment servicing—whether it's changing a hammer or switching a tool—can have dire consequences on production rates. However, with the cutting-edge BoomSafe and Steelwrist hydraulic connection in place, operators can say goodbye to cumbersome manual processes. The BoomSafe system enables operators to switch attachments with just the press of a button: it automatically connects, disconnects, and toggles between tools, minimizing operator effort and maximizing operational efficiency.

One of the most impressive features of the BoomSafe system is its compatibility with the industry-standard Open-S fully automatic quick couplers from Steelwrist. This ensures that the entire changeover process is not only faster but also safer, as there’s no need for operators to engage in potentially hazardous manual tasks such as disconnecting hydraulic hoses or unlocking pins. The result is a smoother operation with reduced risks of hydraulic leaks and pressure drops—common issues that can hamper productivity.

Here are some incredible benefits of the BoomSafe and Steelwrist partnership:

- **Automated Switching:** Enjoy rapid attachment changes, ensuring your production processes are always running smoothly. - **Increased Safety:** With manual intervention eliminated, the risks of injury among operators substantially decrease. - **Improved Efficiency:** No more tedious valve closures or gas purging—experience time savings and operational efficiency.

Beyond its automation prowess, the BoomSafe system offers remote operation capabilities, automated movements, and advanced collision prevention features. Designed specifically to optimize fixed pedestal boom systems, it stands out as a reliable and cost-effective solution in the market. Numerous installations have proven its rugged durability, ease of customization, and minimal maintenance requirements.

As the mining sector continues to advance, TRS’s innovations reflect a commitment to harnessing technology for safer and more efficient operations. Could this be the future of crushing plant automation? Stay tuned as more details emerge from this promising technology that is set to transform the industry landscape!

Brasil (PT)

Brasil (PT)

Canada (EN)

Canada (EN)

Chile (ES)

Chile (ES)

España (ES)

España (ES)

France (FR)

France (FR)

Hong Kong (EN)

Hong Kong (EN)

Italia (IT)

Italia (IT)

日本 (JA)

日本 (JA)

Magyarország (HU)

Magyarország (HU)

Norge (NO)

Norge (NO)

Polska (PL)

Polska (PL)

Schweiz (DE)

Schweiz (DE)

Singapore (EN)

Singapore (EN)

Sverige (SV)

Sverige (SV)

Suomi (FI)

Suomi (FI)

Türkiye (TR)

Türkiye (TR)