Transforming Wood Waste into Affordable Drugs: A Game-Changer in Pharma Production

2025-09-09

Author: John Tan

Cutting Costs on Prescription Drugs

The soaring prices of essential medications, like cholesterol-lowering drugs and antibiotics, mainly stem from high production costs and expensive materials. However, researchers at the University of Maine’s Forest Bioproducts Research Institute (FBRI) have stumbled upon a groundbreaking, sustainable method to produce a key ingredient crucial for a range of pharmaceuticals, potentially slashing prescription drug costs in the U.S.

The Importance of Chirality in Pharmaceuticals

Chiral drugs, which possess a unique property where their molecular structures cannot be superimposed on their mirror images—similar to how left and right hands differ—are among the most expensive on the market. This chirality greatly influences the effectiveness, side effects, and metabolism of a drug. The steep price tag associated with chiral medications largely arises from the costly production of the necessary building blocks, which require intricate synthesis and purification processes.

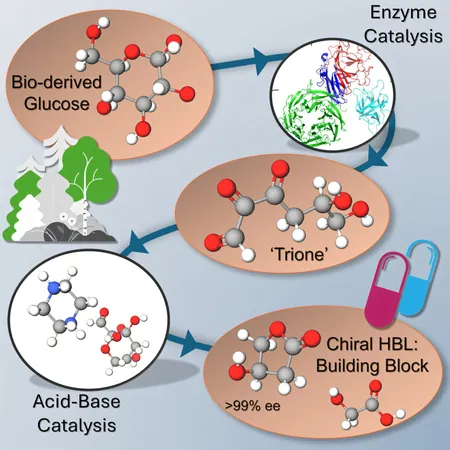

Revolutionary Findings on HBL Production

In a recent study published in Chem, FBRI researchers unveiled a more cost-effective pathway to manufacture a crucial chiral building block known as (S)-3-hydroxy-γ-butyrolactone (HBL) from glucose at impressive concentrations and yields.

A Sustainable Source for HBL

HBL is vital for creating many critical drugs including statins and HIV inhibitors. Remarkably, glucose can be sourced from various lignocellulosic materials—think wood chips, sawdust, and tree branches. This opens up a new sustainable avenue for HBL production while hinting at the potential to create additional consumer products.

Expanding Beyond Pharmaceuticals

Thomas Schwartz, the associate director of FBRI and lead author of the study, noted, "By utilizing other wood sugars like xylose, a byproduct from pulp and paper production, we could innovate new chemicals and building blocks, paving the way for green cleaning products or advanced recyclable plastics."

Overcoming Previous Production Challenges

HBL hasn't always been easy to produce sustainably, often hampered by safety concerns, inefficacy, or expense. Schwartz explained, "Prior methods either yielded low outputs or depended on hazardous materials, making them prohibitively costly. The traditional production process incurs high costs because the chiral center must be artificially added, a feature most petrochemicals lack naturally."

A Bright Future Ahead

With this new sustainable production method, not only could pharmaceutical costs decrease significantly, but it could also usher in an era of eco-friendly alternatives across various industries, showcasing the remarkable potential of leveraging natural resources for modern challenges.

Brasil (PT)

Brasil (PT)

Canada (EN)

Canada (EN)

Chile (ES)

Chile (ES)

Česko (CS)

Česko (CS)

대한민국 (KO)

대한민국 (KO)

España (ES)

España (ES)

France (FR)

France (FR)

Hong Kong (EN)

Hong Kong (EN)

Italia (IT)

Italia (IT)

日本 (JA)

日本 (JA)

Magyarország (HU)

Magyarország (HU)

Norge (NO)

Norge (NO)

Polska (PL)

Polska (PL)

Schweiz (DE)

Schweiz (DE)

Singapore (EN)

Singapore (EN)

Sverige (SV)

Sverige (SV)

Suomi (FI)

Suomi (FI)

Türkiye (TR)

Türkiye (TR)

الإمارات العربية المتحدة (AR)

الإمارات العربية المتحدة (AR)