Sustainable Hydrophobic Cellulose: The Future of Eco-Friendly Packaging and Biomedical Devices?

2024-11-05

Author: Daniel

Introduction

In an exciting breakthrough, a recent study has developed hydrophobic paper by harnessing the powerful mechanical properties and water resistance of cellulose nanofibers. This innovation aims to produce a sustainable, high-performance alternative for packaging and biomedical applications, potentially paving the way for a significant reduction in petroleum-based products.

Research Overview

Titled “Nanocellulose-short peptide self-assembly for improved mechanical strength and barrier performance,” this groundbreaking research was highlighted on the cover of the Journal of Materials Chemistry B. The study was conducted by a team from the "Giulio Natta" Department of Chemistry, Materials and Chemical Engineering at Politecnico di Milano, in collaboration with esteemed institutions like Aalto University, the VTT-Technical Research Centre in Finland, and the SCITEC Institute of the CNR.

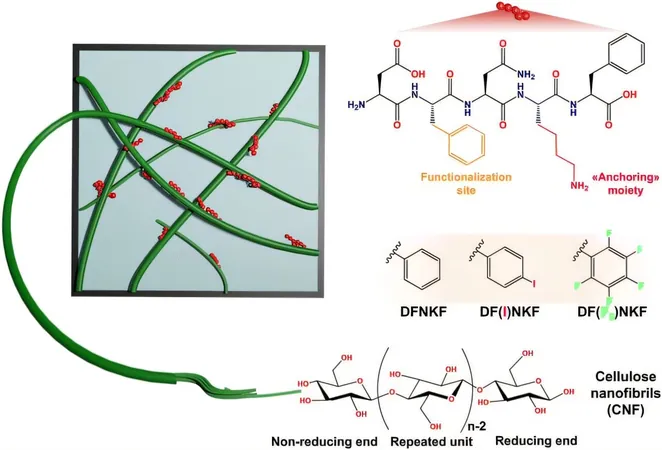

Cellulose Nanofibers (CNFs)

Cellulose nanofibers (CNFs), derived from renewable cellulose, are recognized for their exceptional strength and versatility. The researchers demonstrated how to enhance the properties of CNFs without any chemical modifications, through the addition of short protein sequences, known as peptides. “Our supramolecular approach enables these peptides to bond with nanofibers, significantly boosting their mechanical properties and water resistance,” explains Elisa Marelli, a co-author of the research. Remarkably, even tiny amounts of peptides (less than 0.1%) can lead to considerable improvements in the materials produced, increasing their resistance to stress.

Fluorine Atom Introduction

Furthermore, the team explored the benefits of introducing fluorine atoms into the peptide sequences. This addition enabled the creation of a structured hydrophobic film, resulting in enhanced water resistance while maintaining the material's biocompatibility and sustainability.

Environmental Impact and Future Possibilities

As co-author Pierangelo Metrangolo highlighted, “This advancement unlocks new possibilities for developing biomaterials that can rival petroleum-based materials. We are achieving similar performance levels while considerably lowering environmental impact.” The hybrid materials produced are not only ideal for sustainable packaging—where moisture resistance is crucial—but also show great promise for use in biomedical devices due to their biocompatible nature.

Conclusion

This innovative research not only charts a course toward more environmentally-friendly products but also raises essential questions about the future of material science. Will cellulose nanofibers become the go-to material for sustainable packaging solutions? As companies and consumers alike strive for greener alternatives, the answer may be closer than we think!

Brasil (PT)

Brasil (PT)

Canada (EN)

Canada (EN)

Chile (ES)

Chile (ES)

España (ES)

España (ES)

France (FR)

France (FR)

Hong Kong (EN)

Hong Kong (EN)

Italia (IT)

Italia (IT)

日本 (JA)

日本 (JA)

Magyarország (HU)

Magyarország (HU)

Norge (NO)

Norge (NO)

Polska (PL)

Polska (PL)

Schweiz (DE)

Schweiz (DE)

Singapore (EN)

Singapore (EN)

Sverige (SV)

Sverige (SV)

Suomi (FI)

Suomi (FI)

Türkiye (TR)

Türkiye (TR)