Revolutionizing Temporary Implants: How a New Polymer Coating Slows Down Magnesium Alloy Corrosion

2025-07-11

Author: Rajesh

The Future of Temporary Implants

Imagine undergoing surgery and receiving a temporary implant that naturally dissolves in your body, eliminating the need for an additional painful operation. While this sounds fantastic, designing such implants poses numerous challenges.

Why Magnesium is a Game-Changer

Among various materials, magnesium stands out as a promising candidate for temporary implants due to its biocompatibility. However, its rapid degradation remains a significant hurdle, limiting its practical use.

Alloying for Success: Meet ZK60

To combat this corrosion issue, scientists often alloy magnesium with non-toxic metals. The ZK60 Mg-Zn-Zr alloy shows promise, having favorable mechanical properties, but it still degrades within 12 weeks.

Harnessing the Power of Polymer Coatings

Enter biodegradable polymer coatings! These can effectively slow down corrosion. Researchers are particularly interested in poly (3-hydroxybutyrate) or PHB, a biocompatible polymer, for coating Mg alloys.

Testing under Realistic Conditions

To mirror human physiological conditions, researchers explore dynamic electrolyte flow systems. By studying corrosion in these realistic scenarios, they aim to understand better how well these coatings perform.

A Groundbreaking Study

Recent research published in Electrochimica Acta focused on the corrosion of PHB-coated ZK60, employing advanced techniques like electrochemical impedance spectroscopy (EIS) and scanning electron microscopy (SEM).

Dynamic vs. Static: The Corrosion Showdown

In initial experiments, the ZK60 alloy was tested in modified simulated body fluid (m-SBF). Remarkably, under dynamic conditions, the alloy exhibited more significant degradation compared to static immersion, revealing the aggressive nature of moving electrolytes.

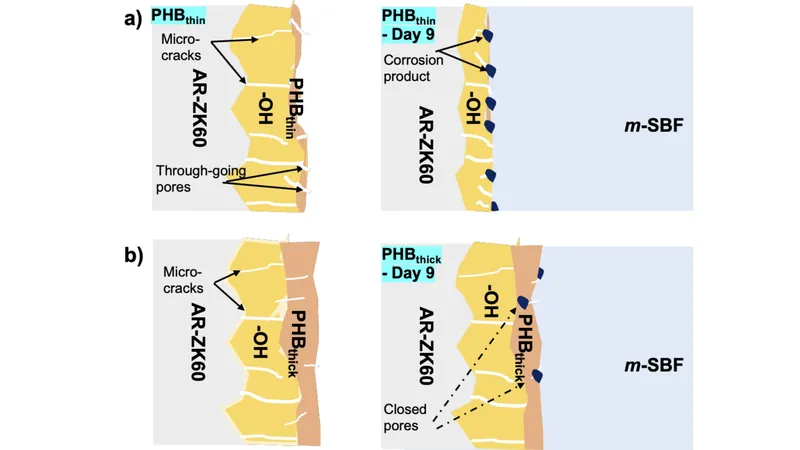

Tweaking Coating Thickness

To mitigate this corrosion, researchers pre-treated the alloy with sodium hydroxide and then applied PHB coatings of varying thickness. Notably, the thin PHB coating showed numerous pores, whereas the thick coating was compact.

Striking Differences in Performance

After nine days of testing, results indicated PHBthin allowed greater electrolyte ingress, leading to increased corrosion. Conversely, PHBthick demonstrated significant protective qualities, showcasing minimal degradation.

Path Forward: Controlling Degradation

This research not only highlights the importance of tuning pore density in polymer coatings but also suggests that corrosion products might offer some level of protection over extended periods.

A Gleam of Hope for Temporary Implants

The implications of these findings are profound. They pave the way for polymer-coated magnesium alloys to be viable options for temporary implants, potentially revolutionizing how we approach bone healing in medical procedures.

Join the Discussion!

This groundbreaking study is part of Science X Dialog, where researchers share their latest findings. Explore more about this initiative and how to get involved!

Brasil (PT)

Brasil (PT)

Canada (EN)

Canada (EN)

Chile (ES)

Chile (ES)

Česko (CS)

Česko (CS)

대한민국 (KO)

대한민국 (KO)

España (ES)

España (ES)

France (FR)

France (FR)

Hong Kong (EN)

Hong Kong (EN)

Italia (IT)

Italia (IT)

日本 (JA)

日本 (JA)

Magyarország (HU)

Magyarország (HU)

Norge (NO)

Norge (NO)

Polska (PL)

Polska (PL)

Schweiz (DE)

Schweiz (DE)

Singapore (EN)

Singapore (EN)

Sverige (SV)

Sverige (SV)

Suomi (FI)

Suomi (FI)

Türkiye (TR)

Türkiye (TR)

الإمارات العربية المتحدة (AR)

الإمارات العربية المتحدة (AR)