Revolutionizing Space Manufacturing: Glasgow University's Cutting-Edge Lab Tests 3D Printed Parts for Orbital Safety

2025-05-23

Author: Jia

Introducing the NextSpace Testrig Lab

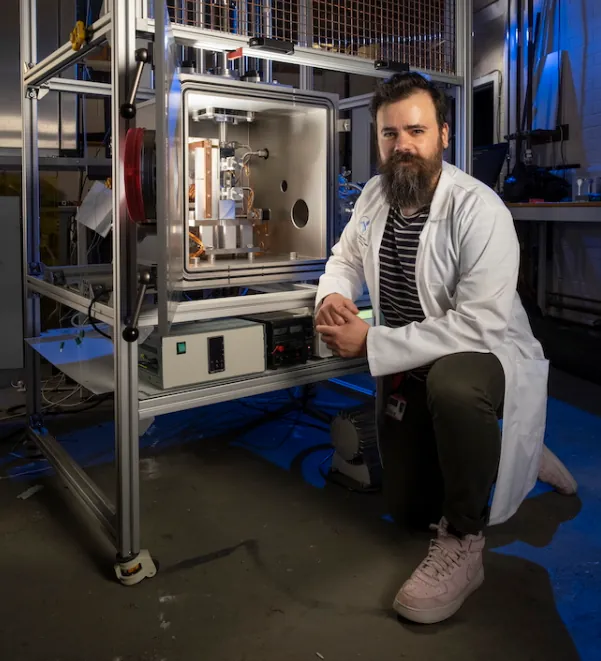

The University of Glasgow has unveiled a groundbreaking facility set to transform how we approach space manufacturing. The NextSpace Testrig lab is designed meticulously to simulate the harsh conditions of outer space, ensuring that 3D printed components can withstand the rigors of orbit while reducing the risk of dangerous debris.

Innovation and Collaboration

Led by Dr. Gilles Bailet and developed in partnership with the Manufacturing Technology Centre and funded by the UK Space Agency, the lab received a significant boost of £253,000 through the Enabling Technology Programme. Dr. Bailet emphasized the tremendous potential of 3D printing technology, allowing for the construction of intricate structures directly in space—think lightweight antennas, solar reflectors, and even habitats for lunar exploration!

Risks of Space Debris

As the race to print spacecraft components in orbit heats up, experts caution about the risks posed by even minute defects in printed materials. These flaws, exacerbated by extreme temperatures and vacuum conditions, could lead to catastrophic failures, sending shrapnel flying through the cosmos and into the paths of satellites.

Testing Under Extreme Conditions

The NextSpace Testrig recreates the unforgiving environment of space using a vacuum chamber that oscillates between a chilling -150°C and an intense +250°C. In this harsh environment, materials face up to 20 kilonewtons of pressure, rigorously testing their resilience to ensure they can survive the conditions of outer space. This facility is pioneering, boasting unique capabilities that no other lab in the world currently offers.

Pioneering the Future of Space Manufacturing

Before the Testrig, Glasgow University had already made strides in low-gravity 3D printing technology, validated through successful European Space Agency parabolic flight tests. The NextSpace Testrig is now open for collaboration, welcoming academics, researchers, and commercial entities worldwide to explore the future of space manufacturing.

Beyond 3D Printing: Space Medical Advancements

Meanwhile, in another exciting frontier, space tech startup Orbital Composites has secured a $1.7 million contract with the U.S. Space Force, focusing on creating antennas in space for satellite broadband and solar power. On the biological side, Redwire has successfully bioprinted human tissue aboard the ISS, marking a major leap forward in space-based medical research that could revolutionize regenerative medicine.

Brasil (PT)

Brasil (PT)

Canada (EN)

Canada (EN)

Chile (ES)

Chile (ES)

Česko (CS)

Česko (CS)

대한민국 (KO)

대한민국 (KO)

España (ES)

España (ES)

France (FR)

France (FR)

Hong Kong (EN)

Hong Kong (EN)

Italia (IT)

Italia (IT)

日本 (JA)

日本 (JA)

Magyarország (HU)

Magyarország (HU)

Norge (NO)

Norge (NO)

Polska (PL)

Polska (PL)

Schweiz (DE)

Schweiz (DE)

Singapore (EN)

Singapore (EN)

Sverige (SV)

Sverige (SV)

Suomi (FI)

Suomi (FI)

Türkiye (TR)

Türkiye (TR)

الإمارات العربية المتحدة (AR)

الإمارات العربية المتحدة (AR)