Revolutionizing Robotics: A 3D Printing Breakthrough Could Change the Way We Create Bionic Devices!

2025-03-18

Author: Siti

Building devices that mimic the graceful movements of human limbs has long posed a significant challenge in robotics. However, a groundbreaking new technique known as "Xstrings," developed by researchers at MIT's Computer Science and Artificial Intelligence Laboratory (CSAIL), has the potential to revolutionize this field by enabling the automated creation of intricate cable-driven mechanisms.

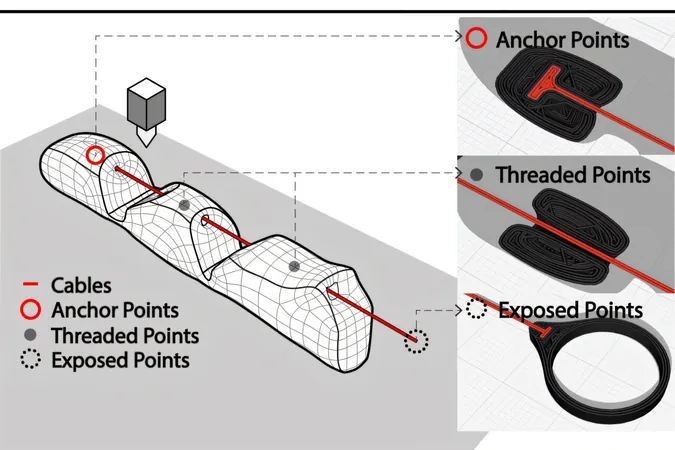

The concept behind cable-driven mechanisms is intriguing: by running a string through various parts of an object, these mechanisms can produce coordinated motions, allowing for movements such as bending, twisting, or curling. Imagine a robotic finger that can curl and grasp by simply pulling a string embedded within it—this is the essence of the innovation.

Xstrings is an all-in-one 3D printing technique that combines a design tool with a manufacturing process. It allows users to create complex bionic robots and dynamic sculptures by assembling various parts, including integrated cables and joints, in a single print job. This automated approach can cut assembly time significantly—up to 40% compared to traditional methods, according to lead researcher Jiaji Li.

At the upcoming 2025 Conference on Human Factors in Computing Systems (CHI2025), the team plans to showcase several vibrant creations developed through Xstrings, including a robotic lizard that walks, a wall sculpture that resembles a peacock's tail, and a multi-functional robotic claw capable of gripping objects.

Users can customize their designs to suit specific needs, such as creating a toy snake with a series of twists or a robotic hand with independently moving fingers. The software allows designers to dictate how cables are anchored, threaded, and where they can be pulled to operate the device's movements. This capability is critical for crafting versatile joints that can flex and adapt as needed.

Xstrings utilizes fused deposition modeling 3D printing, where materials are melted and laid down in layers to construct the desired form. The process involves careful calibration; for instance, researchers determined that printing at temperatures around 260 degrees Celsius with specific speeds optimized the durability of the finished products. These mechanisms withstood over 60,000 pull tests without breaking, showcasing their resilience.

Ultimately, the future of Xstrings could lead to more than just bionic robots and dynamic artwork. The technology's implications may extend to space exploration, enabling rapid fabrication of cable-driven devices in constrained environments such as space stations or extraterrestrial bases. The vision? Creating multifunctional tools and robots that could assist astronauts, all produced through a streamlined printing process.

Jiaji Li articulates the potential impact of this technology: "With Xstrings, anyone with access to a desktop bi-material 3D printer can bring their ideas to fruition, whether that's an interactive art piece or an adaptive piece of clothing." The implications are immense—Xstrings may be the key to unlocking a new era in robotics and beyond, where soft and flexible components can blend seamlessly with robust structures, much like the human body's design.

Stay tuned as we continue to track the developments of this exciting technology. The future of dynamic creation starts now!

Brasil (PT)

Brasil (PT)

Canada (EN)

Canada (EN)

Chile (ES)

Chile (ES)

Česko (CS)

Česko (CS)

대한민국 (KO)

대한민국 (KO)

España (ES)

España (ES)

France (FR)

France (FR)

Hong Kong (EN)

Hong Kong (EN)

Italia (IT)

Italia (IT)

日本 (JA)

日本 (JA)

Magyarország (HU)

Magyarország (HU)

Norge (NO)

Norge (NO)

Polska (PL)

Polska (PL)

Schweiz (DE)

Schweiz (DE)

Singapore (EN)

Singapore (EN)

Sverige (SV)

Sverige (SV)

Suomi (FI)

Suomi (FI)

Türkiye (TR)

Türkiye (TR)

الإمارات العربية المتحدة (AR)

الإمارات العربية المتحدة (AR)