Revolutionizing Prefabricated Construction: The Future of Safe and Efficient Site Planning

2025-09-12

Author: Daniel

Transforming Construction with Smart Site Planning

As the construction industry accelerates its modernization, prefabricated methods are taking center stage. Their ability to minimize waste, enhance quality control, and cut costs makes them a game-changer in the field. However, the journey isn't without roadblocks; prefabricated construction sites grapple with limitations like restricted space, frequent component lifts, and heightened safety risks.

The Challenges of Site Layout Optimization

Efficient Construction Site Layout Planning (CSLP) is essential for optimizing project performance and ensuring safety at prefabricated sites. Yet, current research in this area shows flaws—often lacking precision, facing strict constraints, and having limited applications. Traditional optimization algorithms also struggle with regional search strategies and computational efficiency when it comes to complex multi-objective decisions.

Pioneering Research at Wuhan University of Technology

In response to these challenges, researchers Junwu Wang, Zhihao Huang, and Yinghui Song from Wuhan University of Technology have embarked on groundbreaking research titled "Intelligent Planning of Safe and Economical Construction Sites: Theory and Practice of Hybrid Multi-Objective Decision Making." Their work aims to revolutionize the Prefabricated Component Construction Site Layout Planning (PCCSLP) process.

Introducing the HMSIDBO Algorithm

Focused on boosting construction efficiency while minimizing safety risks, the researchers developed a multi-objective CSLP model. To solve this, they introduced a cutting-edge heuristic approach known as the Hybrid Multi-Strategy Improvement Dung Beetle Optimizer (HMSIDBO). This innovative algorithm excels in balancing global exploration and local development, overcoming the limitations of the traditional Dung Beetle Optimizer (DBO) through new strategies such as Bernoulli mapping and a T-distribution perturbation.

Setting New Standards in Optimization

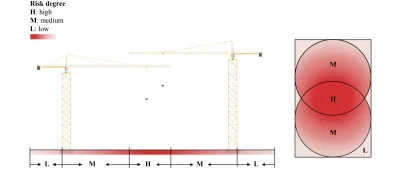

The study formulates a detailed mathematical model for PCCSLP, targeting three key minimization goals: reducing horizontal transportation time for tower cranes, shortening the lifting path lengths of components, and decreasing the overlap of work areas for multiple cranes. Additionally, it incorporates seven vital constraints to ensure realistic applications.

Proven Results from Real-World Applications

A case study conducted on prefabricated residential projects in Sanya validates the effectiveness and practicality of this proposed method. The findings reveal that the HMSIDBO-PCCSLP optimization scheme significantly enhances each targeted objective by an impressive 18% to 75%. Compared to traditional Genetic Algorithms, HMSIDBO not only outperforms in speed but also offers superior resolution accuracy.

A Leap Towards Safer Sites

In comparison to other popular algorithms like Particle Swarm Optimization and Whale Optimization, HMSIDBO showcases remarkable advancements in iterative speed and global search capabilities. Notably, the study reported a reduction of 18.3% in tower crane transportation time and a considerable 23.4% decrease in hazardous areas around falling components. Overlapping workspaces were cut down by an astonishing 74.3%.

Laying the Groundwork for Intelligent Construction

This pioneering research bridges the gap between data collection and complex multi-objective optimization, setting the stage for intelligent construction site practices. It serves as a vital resource for the efficient and safe management of prefabricated construction, heralding a new era where safety and efficiency go hand in hand.

Brasil (PT)

Brasil (PT)

Canada (EN)

Canada (EN)

Chile (ES)

Chile (ES)

Česko (CS)

Česko (CS)

대한민국 (KO)

대한민국 (KO)

España (ES)

España (ES)

France (FR)

France (FR)

Hong Kong (EN)

Hong Kong (EN)

Italia (IT)

Italia (IT)

日本 (JA)

日本 (JA)

Magyarország (HU)

Magyarország (HU)

Norge (NO)

Norge (NO)

Polska (PL)

Polska (PL)

Schweiz (DE)

Schweiz (DE)

Singapore (EN)

Singapore (EN)

Sverige (SV)

Sverige (SV)

Suomi (FI)

Suomi (FI)

Türkiye (TR)

Türkiye (TR)

الإمارات العربية المتحدة (AR)

الإمارات العربية المتحدة (AR)