Revolutionizing Polymer Production: Scientists Develop a Predictive Model for Advanced Material Design

2025-06-11

Author: Daniel

Imagine baking a soufflé with only a list of ingredients but no measurements or temperatures. The chaos of trial and error can lead to wasted time and resources. Now, what if you had a model that could predict the perfect soufflé before any mixing began? This dream is becoming a reality thanks to groundbreaking research at the Beckman Institute for Advanced Science and Technology.

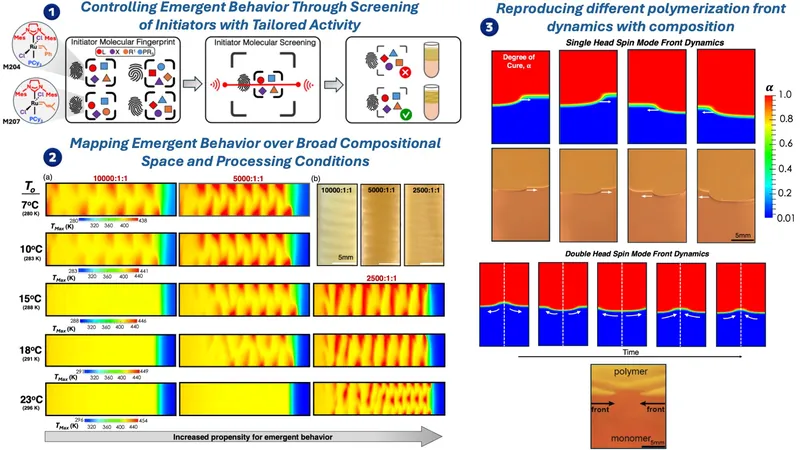

In a bold leap for the field of polymer science, an interdisciplinary team led by Professor Philippe Geubelle has created a computational model that maps out the 'recipe' for patterning polymers, allowing manufacturers to design materials with enhanced properties before even entering the lab. "This means we can engineer materials for specific functionalities—like greater strength or lighter weight—through simulations," explained Jeffrey Moore, a prominent figure in chemistry at the University of Illinois Urbana-Champaign.

The researchers have focused on a technique called Frontal Ring-Opening Metathesis Polymerization (FROMP), likened to how a storm front moves through an area. Much like a weather forecast, their model provides predictions on how chemical reactions can accelerate the formation of complex polymer structures, transforming liquid mixtures into solid materials through localized heat.

Many common materials—like plastics and rubbers—are a product of labor-intensive methods that often lack the self-organizing features found in nature. With FROMP, the team has discovered a way to create periodic patterns similar to those seen in high-performance natural materials, enhancing their functionality.

Patterns in nature, such as the spiral of DNA or the branching of trees, arise spontaneously and have critical functions. Inspired by these biological systems, the research team has developed a system to predict and induce pattern formation in synthetic polymers.

According to primary researcher Anna Cramblitt, "We've created a framework that reveals how minor changes in chemical equilibrium can lead to the development of complex patterns. It's like uncovering the secret recipe for making remarkably patterned materials!" This discovery allows precise control over key reaction steps essential for pattern formation.

By exploring the chemistry behind each stage of polymerization, the researchers have established that fine-tuning reaction kinetics and thermal transport can encourage various material structures—from uniformly stiff to alternately soft and hard.

The team is excited about the newfound design freedom their research provides. Looking ahead, they plan to collaborate with MIT experts to merge their findings with advanced modeling techniques. They hope to push the boundaries of material design, enabling the creation of sustainable, bioinspired materials with superior properties.

With this predictive model, the future of polymer science looks bright, much like the perfect soufflé resting in the oven—waiting to be revealed in all its glorious complexity.

Brasil (PT)

Brasil (PT)

Canada (EN)

Canada (EN)

Chile (ES)

Chile (ES)

Česko (CS)

Česko (CS)

대한민국 (KO)

대한민국 (KO)

España (ES)

España (ES)

France (FR)

France (FR)

Hong Kong (EN)

Hong Kong (EN)

Italia (IT)

Italia (IT)

日本 (JA)

日本 (JA)

Magyarország (HU)

Magyarország (HU)

Norge (NO)

Norge (NO)

Polska (PL)

Polska (PL)

Schweiz (DE)

Schweiz (DE)

Singapore (EN)

Singapore (EN)

Sverige (SV)

Sverige (SV)

Suomi (FI)

Suomi (FI)

Türkiye (TR)

Türkiye (TR)

الإمارات العربية المتحدة (AR)

الإمارات العربية المتحدة (AR)