Revolutionizing Nanoparticle Production: A Groundbreaking Innovation in Flame Aerosol Technology!

2024-11-05

Author: Sarah

Introduction

Since ancient times, fire has played a pivotal role in transforming raw materials into valuable goods, whether it be creating pottery or glass. This tradition continues today, notably in industries that utilize flame aerosol synthesis to produce nanoparticles, which serve as critical components in numerous applications ranging from inks to advanced air filters.

Challenges in Conventional Flame Aerosol Synthesis

However, the conventional flame aerosol synthesis techniques are not without their hurdles. Key challenges include difficulties in flame manipulation, precise control over the size and distribution of nanoparticles, and prohibitively high costs. Fortunately, two innovative studies led by engineers at the University at Buffalo are set to change this narrative.

Innovative Flame Aerosol System

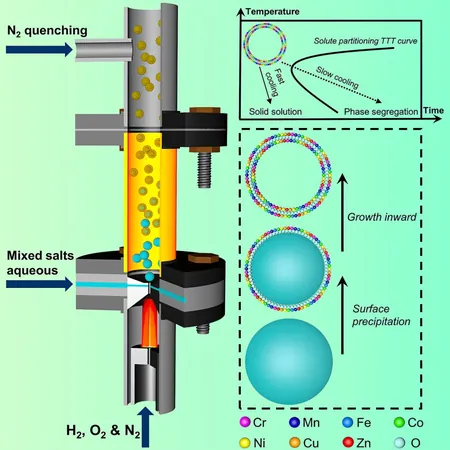

These researchers have developed a unique flame aerosol system which is versatile, user-friendly, and cost-effective. The latest of their studies, recently published in *Nature Communications*, details the application of this technology to create metal-organic frameworks (MOFs). These porous nanomaterials have wide-ranging uses in energy, environmental science, and healthcare.

First Application of Flame Aerosol Technology to MOFs

According to Dr. Mark Swihart, a leading author of the study and chair of the Department of Chemical and Biological Engineering, "This is, to the best of our knowledge, the first time that flame aerosol technology has been applied to create MOFs." Traditionally, MOFs are synthesized through liquid chemical reactions, a method that, while effective, can be slow and expensive. In contrast, the new flame aerosol system streamlines the process, potentially yielding results that are both faster and more economical.

Unique Attributes of MOFs

While the MOFs produced through this system may exhibit lower porosity than their traditional counterparts, they possess unique attributes such as small grain size, short-range ordered structures, and exceptional thermal stability. These qualities open doors to innovative materials and commercial applications, pushing the boundaries of what is possible in various fields.

Seamless Mixing of Metal Elements

Moreover, this flame aerosol system tackles thermodynamic barriers, enabling the seamless mixing of different metal elements into a single MOF, enhancing its suitability for applications like catalysis, sensing, and energy storage.

Previous Study on High-Entropy Ceramic Nanomaterials

In a previous study published in *Matter*, the researchers highlighted the system's capability for producing high-entropy ceramic nanomaterials. These highly stable nanomaterials, composed of multiple elements in nearly equal proportions, demonstrate remarkable properties that make them ideal for several applications, similar to MOFs. Remarkably, the team showcased its versatility by crafting nanoparticles that included up to 22 elements. Their experiments even led to the development of a carbon dioxide reduction catalyst that shows durability and efficacy far surpassing that of traditional catalysts.

Conclusion

Swihart summarizes the significance of this technique: "The flame reactor is a scalable, one-step, and incredibly versatile way to fabricate high-entropy nanoceramics, as well as other materials." This breakthrough is poised to revolutionize the production of nanoparticles, paving the way for more efficient manufacturing processes and innovative applications that could ultimately enhance our everyday lives. Stay tuned as further developments unfold in this captivating field of research!

Brasil (PT)

Brasil (PT)

Canada (EN)

Canada (EN)

Chile (ES)

Chile (ES)

España (ES)

España (ES)

France (FR)

France (FR)

Hong Kong (EN)

Hong Kong (EN)

Italia (IT)

Italia (IT)

日本 (JA)

日本 (JA)

Magyarország (HU)

Magyarország (HU)

Norge (NO)

Norge (NO)

Polska (PL)

Polska (PL)

Schweiz (DE)

Schweiz (DE)

Singapore (EN)

Singapore (EN)

Sverige (SV)

Sverige (SV)

Suomi (FI)

Suomi (FI)

Türkiye (TR)

Türkiye (TR)