Revolutionizing MXene Production: Going Green with Electricity!

2025-04-14

Author: Jia

The Future of Materials Science Has Arrived!

The groundbreaking nanomaterial MXene, essential for battery technology and high-performance lubrication, has undergone a radical transformation in its production process. Researchers at TU Wien are leading the charge to eliminate the toxic methods previously used, promising a safer and more efficient way to create this incredible material.

What Are MXenes?

MXenes, pronounced ‘Maxenes,’ are a stunning class of materials derived primarily from titanium and carbon. Their unique properties make them standout candidates for applications such as electromagnetic shielding, energy storage, and innovative sensors. At TU Wien, scientists have even uncovered their extraordinary potential as solid lubricants, capable of functioning under extreme conditions, including the harsh environments of space.

Ditching Toxicity: A Green Milestone!

Historically, creating MXenes involved using hydrofluoric acid to etch aluminum out of MAX phases, a method fraught with danger and environmental concerns. Pierluigi Bilotto and his team recognized the limitations of this approach, as handling hydrofluoric acid necessitated costly lab equipment and strict safety regulations, hindering industrial scalability.

A Game-Changing Synthesis Method!

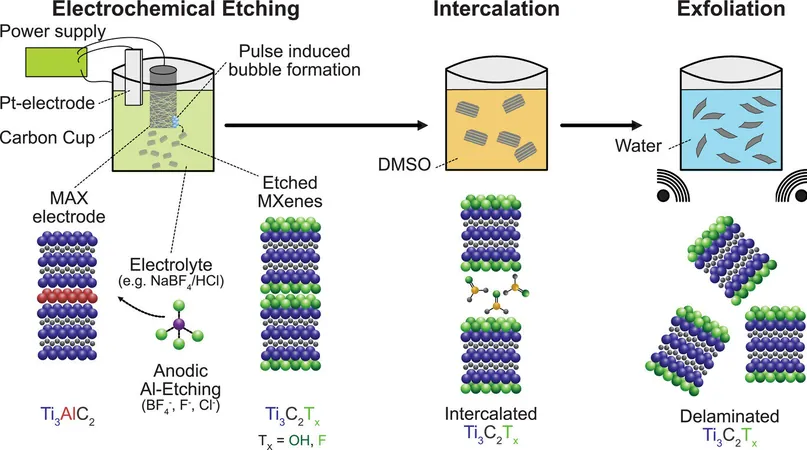

In a remarkable breakthrough, the TU Wien team has developed a method utilizing electricity to replace the harmful acid. By applying an electrical voltage, they trigger a reaction that selectively removes aluminum atoms from the MAX phase, yielding what they term electrochemical MXenes (EC-MXenes). This innovative process marks a monumental shift in MXene production, making it not only more efficient but also environmentally friendly.

Harnessing Electrochemistry for High-Quality Production!

The researchers discovered that employing well-timed electrical pulses during synthesis enhances the overall quality of the MXenes. This technique fosters the formation of tiny hydrogen bubbles that clean and reactivate the surfaces of MAX phases, allowing for prolonged electrochemical reactions and a bountiful yield of EC-MXenes.

Cutting-Edge Analysis Proves Their Worth!

Post-production, the characteristics of these new MXenes were examined through advanced methodologies, including Atomic Force Microscopy and Raman spectroscopy. The findings revealed that the properties of EC-MXenes are at least as impressive as their counterparts produced with toxic acids.

Simplifying MXene Production: A Vision for the Future!

Bilotto’s ambitious vision is to simplify the synthesis of MXenes so that it can be done in any kitchen. With the advent of this new method, we are on the brink of achieving that dream, opening doors for widespread utilization of MXenes in various industries.

Brasil (PT)

Brasil (PT)

Canada (EN)

Canada (EN)

Chile (ES)

Chile (ES)

Česko (CS)

Česko (CS)

대한민국 (KO)

대한민국 (KO)

España (ES)

España (ES)

France (FR)

France (FR)

Hong Kong (EN)

Hong Kong (EN)

Italia (IT)

Italia (IT)

日本 (JA)

日本 (JA)

Magyarország (HU)

Magyarország (HU)

Norge (NO)

Norge (NO)

Polska (PL)

Polska (PL)

Schweiz (DE)

Schweiz (DE)

Singapore (EN)

Singapore (EN)

Sverige (SV)

Sverige (SV)

Suomi (FI)

Suomi (FI)

Türkiye (TR)

Türkiye (TR)

الإمارات العربية المتحدة (AR)

الإمارات العربية المتحدة (AR)