Revolutionizing Material Production: Inline Color Measurement in Extruder Heads

2025-08-11

Author: Jia

Enhancing Product Quality in Manufacturing

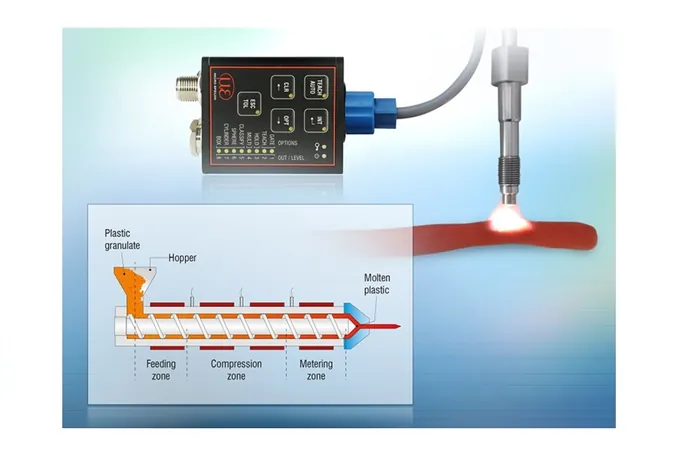

When producing solid-to-viscous materials like gelatin, syrup, and various plastics, precision is key. As these materials are extruded, they undergo continuous compression under high pressure. It's crucial to manage the temperature carefully during this process; overheating can lead to burning and unwanted discolouration. Enter Micro-Epsilon's advanced color sensors, designed specifically to monitor and ensure the quality of these extruded materials.

Tough Conditions, Superior Solutions

Extruder heads pose a significant challenge for sensor integration, operating at pressures of up to 200 bar and temperatures reaching 250°C. To tackle these harsh conditions, Micro-Epsilon utilizes specially crafted fiber optic sensors. The colorSENSOR CFS is mounted directly in the extruder, accessible via a robust fitting, ensuring it can withstand extreme environments. With impressive durability and repeatability rates of ?E < 0.3, these sensors are essential for maintaining high production standards.

Innovative Measurement Techniques

Different materials require tailored measurement approaches. For transparent materials like gelatin, the CFS3-S-T250 transmission sensor measures color in transmission, while opaque plastics are evaluated using the reflection method through the CFS4-S-T250 sensor. This allows for accurate measurement directly at the interior wall of the extruder, making it an integral part of the process control.

Cutting-Edge Controller Technology

To facilitate inline color measurement, a dedicated controller is necessary. The newly launched colorSENSOR CFO250 controller from Micro-Epsilon boasts an impressive data output rate of up to 500 Hz. This versatility makes it ideal for high-speed applications, like monitoring mixing processes and conducting in-quality inspections in filling plants.

Rapid and Accurate Color Evaluation

The CFO250 controller excels in rapid color evaluations, processing measurements at speeds up to 30 kHz. It compares predefined color standards with real-time data to yield immediate insights, helping manufacturers maintain consistent quality. Users can access both processed results and raw data in Lab or XYZ color spaces through various interfaces, ensuring seamless integration with production systems.

User-Friendly Features and Software

With a web interface that allows for the registration of 254 color groups, the CFO250 simplifies the user experience. It intelligently adjusts illumination, averaging, and signal amplification to suit current measurement conditions. Moreover, Micro-Epsilon provides the sensorTOOL software, enabling high-frequency data recordings that bolster quality control processes.

In an industry where precision and efficiency are paramount, Micro-Epsilon's innovative solutions in inline color measurement are setting new standards, helping manufacturers achieve top-notch product quality while optimizing their extruding processes.

Brasil (PT)

Brasil (PT)

Canada (EN)

Canada (EN)

Chile (ES)

Chile (ES)

Česko (CS)

Česko (CS)

대한민국 (KO)

대한민국 (KO)

España (ES)

España (ES)

France (FR)

France (FR)

Hong Kong (EN)

Hong Kong (EN)

Italia (IT)

Italia (IT)

日本 (JA)

日本 (JA)

Magyarország (HU)

Magyarország (HU)

Norge (NO)

Norge (NO)

Polska (PL)

Polska (PL)

Schweiz (DE)

Schweiz (DE)

Singapore (EN)

Singapore (EN)

Sverige (SV)

Sverige (SV)

Suomi (FI)

Suomi (FI)

Türkiye (TR)

Türkiye (TR)

الإمارات العربية المتحدة (AR)

الإمارات العربية المتحدة (AR)