Revolutionizing Material Design: How AI is Creating Resilient Metamaterials

2025-07-24

Author: Jia

Unlocking the Future of Industrial Materials

Imagine materials that are not only lightweight but also incredibly strong—capable of easing impacts while absorbing vibrations. From car bumpers to aerospace panels, the success of these innovations hinges on the development of advanced cellular materials. However, traditional manufacturing flaws often doom these products to fail before they even hit the market.

A Groundbreaking AI Approach

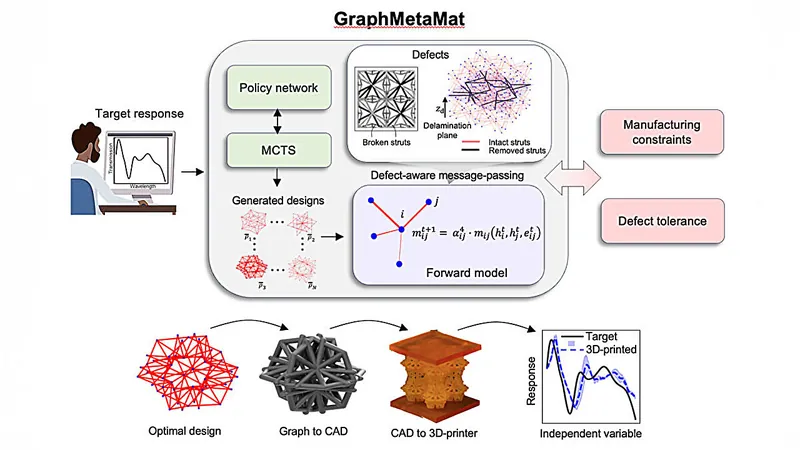

Enter a pioneering team from UC Berkeley, who have harnessed the power of artificial intelligence to revolutionize the design of 3D truss metamaterials. Spearheaded by associate professor Xiaoyu (Rayne) Zheng, this initiative has birthed a remarkable new framework known as GraphMetaMat. This dynamic modeling technique leverages deep learning to seamlessly blend design creativity with practical manufacturability, all while enhancing defect tolerance.

"Most AI endeavors in material design have focused on ideal performances in theoretical scenarios," Zheng explained. "Our approach revolutionizes this by creating designs specifically aimed at real-world manufacturing processes, ensuring they endure any defects that may arise during production."

Breaking the Boundaries of Traditional Design

While existing design methods often struggle with complex non-linear properties vital for applications like automotive safety and athletic gear, GraphMetaMat thrives where others falter. Designed capable of generating intricate performance attributes, it surpasses the limitations faced by conventional design software.

Zheng elaborated, "Techniques like topology optimization can predict basic material responses but fail in complex scenarios where energy absorption is critical. Our framework addresses these shortcomings head-on."

Harnessing Deep Learning for Innovative Solutions

To solve the challenge of limited training data for metamaterial designs, the team ingeniously combined several advanced deep learning strategies, including reinforcement learning and Monte Carlo tree search. This impressive synergy empowers users to conceive metamaterials from the ground up, customizing inputs to achieve desired stress-strain curves or vibration attenuation.

Transforming Challenges into Opportunities

What truly sets GraphMetaMat apart is its capacity to integrate engineering constraints, particularly those related to manufacturing flaws. "This is revolutionary; it guarantees that our metamaterials can still perform under the strain of real-world production imperfections," Zheng noted.

Proving the Concept: Performance Beyond Traditional Materials

In their proof of concept, the team successfully designed lightweight truss metamaterials tailored for energy absorption and vibration mitigation. Remarkably, these newly engineered materials consistently outpace traditional counterparts, including polymer foams and phononic crystals.

Zheng states, "Our findings suggest that GraphMetaMat is not just a tool but a potential paradigm shift in material design, paving the way for high-performance metamaterials with real-world applicability."

The Future is Bright for Metamaterials

As this groundbreaking research unfolds, one thing is clear: the future of high-performance materials is here, and it's being shaped by cutting-edge AI technology.

Brasil (PT)

Brasil (PT)

Canada (EN)

Canada (EN)

Chile (ES)

Chile (ES)

Česko (CS)

Česko (CS)

대한민국 (KO)

대한민국 (KO)

España (ES)

España (ES)

France (FR)

France (FR)

Hong Kong (EN)

Hong Kong (EN)

Italia (IT)

Italia (IT)

日本 (JA)

日本 (JA)

Magyarország (HU)

Magyarország (HU)

Norge (NO)

Norge (NO)

Polska (PL)

Polska (PL)

Schweiz (DE)

Schweiz (DE)

Singapore (EN)

Singapore (EN)

Sverige (SV)

Sverige (SV)

Suomi (FI)

Suomi (FI)

Türkiye (TR)

Türkiye (TR)

الإمارات العربية المتحدة (AR)

الإمارات العربية المتحدة (AR)