Revolutionizing Lunar Construction: 3D Printing with Regolith Takes a Leap Forward

2025-04-28

Author: Nur

A Groundbreaking Leap in 3D Printing from Lunar Materials

Exciting advancements in 3D printing using lunar regolith are paving the way for the future of space construction. Various projects have explored this ambitious endeavor, yet most rely on additives like polymers or salt water as binding agents. A recent groundbreaking study by Julien Garnier and colleagues from the University of Toulouse, published in Acta Astronautica, thrusts the spotlight on a revolutionary method that aims to create compression-hardened 3D-printed materials using solely lunar regolith.

The High Cost of Space: Why Additives Aren't Ideal

Transporting materials to space is notoriously expensive, making any 3D printing technology that depends on shipping large quantities from Earth less viable. Companies like AI Spacefactory have explored using Earth-sourced polymers, but the complexities and costs associated with transporting these additives to the Moon place their projects at a disadvantage.

Next-Level Materials: Basalt of Pic d'Ysson

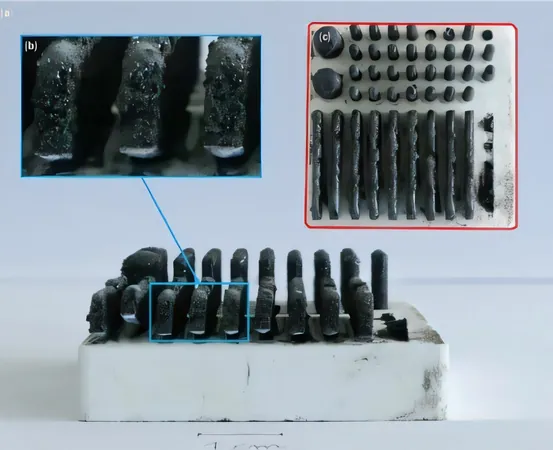

Dr. Garnier's research aims to circumvent this costly requirement by employing selective laser melting (SLM) on an innovative lunar regolith analog known as Basalt of Pic d'Ysson (BPY). Extracted from an ancient volcano in France, BPY boasts a chemical and mineral composition remarkably similar to that of lunar basalt, making it an attractive substitute for terrestrial 3D printing trials.

Previous Research Hits a Wall with BPY Strength

Despite its potential, previous studies have raised concerns about BPY's appropriateness for 3D printing due to inadequate compressive strength. On the Moon, structures still face stresses despite lower gravity, and if a material cannot withstand these forces, it’s impractical as a building component.

Decoding the Strength: The Science Behind BPY

Measurements of compressive strength in 3D-printed BPY yielded mixed results, with techniques like Powder Bed Fusion yielding a compression strength of 4.2 MPa – just above that of a standard masonry brick – with almost half the material composed of holes. While combining BPY with a geopolymer can bolster its strength, this still necessitates importing the geopolymer from Earth.

The Game Changer: Crystalline vs. Amorphous Structure

In their quest for stronger materials, Dr. Garnier and his team experimented with the structural properties of BPY powders, comparing crystalline and amorphous forms. The results were staggering: crystalline powders boasted double the compressive strength of their amorphous counterparts. This discovery underscores the critical role of regolith structure in the construction of lunar bases.

A Promising Future for Lunar Habitats

As researchers delve deeper into the properties of lunar regolith, the dream of establishing self-sufficient habitats on the Moon draws nearer. By refining 3D printing methods and focusing on the unique attributes of lunar materials, we are one step closer to making lunar construction a reality.

Brasil (PT)

Brasil (PT)

Canada (EN)

Canada (EN)

Chile (ES)

Chile (ES)

Česko (CS)

Česko (CS)

대한민국 (KO)

대한민국 (KO)

España (ES)

España (ES)

France (FR)

France (FR)

Hong Kong (EN)

Hong Kong (EN)

Italia (IT)

Italia (IT)

日本 (JA)

日本 (JA)

Magyarország (HU)

Magyarország (HU)

Norge (NO)

Norge (NO)

Polska (PL)

Polska (PL)

Schweiz (DE)

Schweiz (DE)

Singapore (EN)

Singapore (EN)

Sverige (SV)

Sverige (SV)

Suomi (FI)

Suomi (FI)

Türkiye (TR)

Türkiye (TR)

الإمارات العربية المتحدة (AR)

الإمارات العربية المتحدة (AR)