Revolutionizing Diabetes Management: Upcycling E-Waste to Create Cutting-Edge Glucose Sensors!

2024-09-18

Author: Daniel

Introduction to E-Waste and Diabetes Management

As electronic devices proliferate in our daily lives, the issue of electronic waste (e-waste) has reached critical levels, demanding urgent attention and innovative solutions. Traditional recycling techniques for printed circuit boards (PCBs) are typically divided into physical methods, which involve mechanical disassembly and separation, and chemical methods, which leverage hydrometallurgy or pyrometallurgy. Unfortunately, these conventional approaches can be costly and environmentally damaging, leading researchers to explore more sustainable options.

Enter laser technology, a game-changer in the realm of e-waste recycling! This innovative method provides a step towards recovering valuable metals from PCBs while being environmentally friendly and highly efficient.

Innovations in Diabetes Management

On another front, managing diabetes requires effective ways to monitor glucose levels. Recent advancements have shifted focus toward non-invasive glucose detection methods, particularly through the analysis of sweat, which contains not only glucose but other critical biomarkers. Electrochemical sensors, especially non-enzymatic glucose sensors, have garnered attention due to their cost-effectiveness and stability.

A breakthrough material in this field is copper oxide (CuxO), known for its biocompatibility and exceptional sensitivity to glucose. However, traditional production methods for copper oxide electrodes have often been cumbersome, expensive, and reliant on hazardous chemicals. Thankfully, the advent of laser-induced processes presents a cleaner, faster, and scalable method for crafting copper-based electrodes.

Groundbreaking Study by Guijun Li and Team

In a groundbreaking study, Guijun Li and his team at Hong Kong University of Science and Technology unveiled a novel laser-induced transfer technique that repurposes copper from discarded e-waste to create portable glucose sensor electrodes. This low-cost and scalable process allows for the effective production of h-CuxO electrodes directly from discarded PCBs.

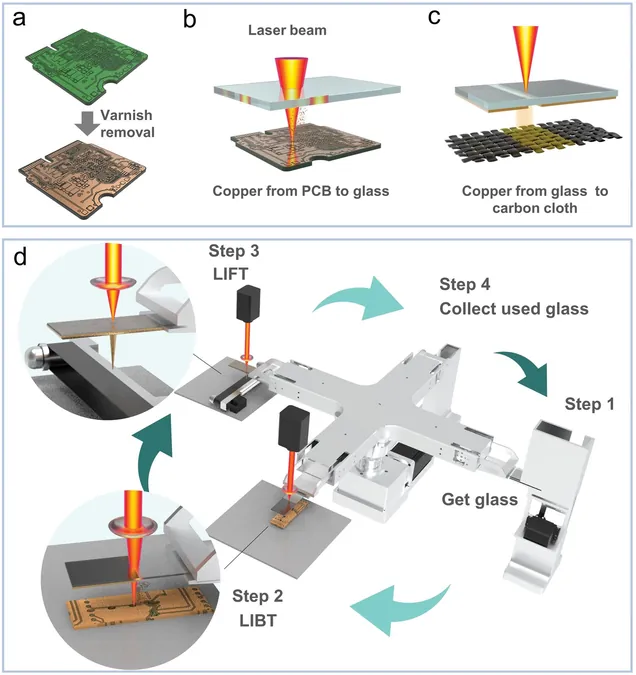

The remarkable research, featured in the journal Nano-Micro Letters, outlines the innovative steps taken by the team. Initially, a laser ablation technique was employed to remove the protective coating from the PCB surface. Following this, laser-induced backward transfer (LIBT) enabled the efficient transfer of copper from the PCB to a glass substrate, which was then followed by laser-induced forward transfer (LIFT) to deposit the copper onto a carbon cloth substrate, leading to the creation of high-performance glucose sensors.

Performance and Reliability of h-CuxO Electrodes

What's truly astounding is the performance of the novel h-CuxO electrodes. When compared with commercial Cu2O and CuO nanoparticles, the h-CuxO-EA electrode outperformed them significantly, achieving an impressive sensitivity of 9.893 mA mM-1 cm-2 (R²=0.996) with a detection limit of just 0.34 µM. Additionally, it demonstrated excellent resistance to interference during glucose detection, retaining nearly 100% of its current response even after eight weeks in tests simulating artificial sweat. This remarkable long-term stability positions the h-CuxO-EA electrode as a frontrunner in glucose detection technology.

Moreover, the research team developed a compact electrochemical workstation capable of wirelessly transmitting real-time data to smartphones via Bluetooth. This miniaturized system's electrochemical readings were confirmed to be consistent with those from traditional PARSTAT workstations, proving its reliability and effectiveness.

Conclusion and Future Implications

With varying glucose concentrations, the h-CuₓO-EA electrode showcased a solid correlation between current response and glucose levels, achieving a remarkable sensitivity of 61.67 µA mol-1. Notably, tests with artificial sweat containing five different glucose concentrations yielded values that closely aligned with actual levels.

The initiative not only enhances the portability and scalability of glucose monitoring devices but also represents a significant leap towards integrating advanced technology into everyday diabetes management. In a world where e-waste continues to grow, the promise of upcycling electronic scrap into life-saving innovations may just be the breakthrough we need!

Stay tuned as this revolutionary process could transform both e-waste management and diabetes care, paving the way for a healthier, more sustainable future!

Brasil (PT)

Brasil (PT)

Canada (EN)

Canada (EN)

Chile (ES)

Chile (ES)

Česko (CS)

Česko (CS)

대한민국 (KO)

대한민국 (KO)

España (ES)

España (ES)

France (FR)

France (FR)

Hong Kong (EN)

Hong Kong (EN)

Italia (IT)

Italia (IT)

日本 (JA)

日本 (JA)

Magyarország (HU)

Magyarország (HU)

Norge (NO)

Norge (NO)

Polska (PL)

Polska (PL)

Schweiz (DE)

Schweiz (DE)

Singapore (EN)

Singapore (EN)

Sverige (SV)

Sverige (SV)

Suomi (FI)

Suomi (FI)

Türkiye (TR)

Türkiye (TR)

الإمارات العربية المتحدة (AR)

الإمارات العربية المتحدة (AR)