Revolutionizing Construction: Smart Strategies for Safer and Cheaper Sites

2025-09-12

Author: Wei Ling

Construction's Next Frontier: The Shift to Prefabrication

As the construction industry continues to modernize, prefabricated construction is rising to the forefront. Known for slashing waste, boosting quality control, and accelerating timelines, these construction methods offer a promising future. However, prefabricated sites aren't without their hurdles—tight spaces, frequent component hoisting, and significant safety risks linger as pressing challenges.

Maximizing Efficiency and Safety on Construction Sites

To tackle these issues, the expert team of Junwu WANG, Zhihao HUANG, and Yinghui SONG from Wuhan University of Technology have delved into groundbreaking research titled "Intelligent Planning of Safe and Economical Construction Sites: Theory and Practice of Hybrid Multi-Objective Decision Making." This study zeroes in on enhancing the layout of prefabricated component sites, balancing construction efficiency with safety.

A Game-Changer in Decision-Making: The HMSIDBO Algorithm

The researchers introduced an innovative heuristic algorithm—the Hybrid Multi-Strategy Improvement Dung Beetle Optimizer (HMSIDBO)—that revolutionizes how construction layout planning is approached. Unlike traditional methods, which often falter under strict constraints and inefficiencies, HMSIDBO skillfully balances global exploration with local optimization, thanks to its advanced strategies including Bernoulli mapping, Levy flights, and T-distribution perturbations.

Threefold Objectives for Optimal Site Layout

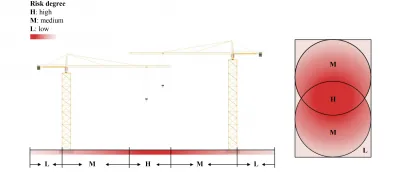

The study establishes a comprehensive model aiming to minimize three key areas: the horizontal transportation time of tower cranes, the lifting path lengths of components, and the overlap of tower cranes’ working areas. Along with these goals, the model also adheres to stringent constraints ensuring operational safety and efficiency. A real-world application in Sanya's prefabricated residential projects confirmed the significant practicality of their method.

Remarkable Results and Future Implications

The results were astounding! The HMSIDBO-PCCSLP optimization scheme outperformed the previous layout by enhancing all objectives by 18% to 75%. When pitted against the Genetic Algorithm, HMSIDBO exhibited a remarkable speed and precision upgrade. It outshone its competitors—notably the Dung Beetle Optimizer, Particle Swarm Optimization, and Whale Optimization—by demonstrating superior global exploration and iterative efficiency. Crucially, the average transportation time for tower cranes dropped by 18.3%, while hazardous areas associated with prefabricated components plummeted by 23.4% and overlapping work areas decreased by a staggering 74.3%.

Building a Safer Future for Prefabricated Construction

In conclusion, this research not only bridges the gap between data collection and optimization but lays a solid foundation for implementing intelligent site layout practices. It provides essential scientific backing for the effective and safe management of prefabricated construction sites, heralding a safer, more efficient future for the construction industry.

Brasil (PT)

Brasil (PT)

Canada (EN)

Canada (EN)

Chile (ES)

Chile (ES)

Česko (CS)

Česko (CS)

대한민국 (KO)

대한민국 (KO)

España (ES)

España (ES)

France (FR)

France (FR)

Hong Kong (EN)

Hong Kong (EN)

Italia (IT)

Italia (IT)

日本 (JA)

日本 (JA)

Magyarország (HU)

Magyarország (HU)

Norge (NO)

Norge (NO)

Polska (PL)

Polska (PL)

Schweiz (DE)

Schweiz (DE)

Singapore (EN)

Singapore (EN)

Sverige (SV)

Sverige (SV)

Suomi (FI)

Suomi (FI)

Türkiye (TR)

Türkiye (TR)

الإمارات العربية المتحدة (AR)

الإمارات العربية المتحدة (AR)