Revolutionizing Bone Repair: The Breakthrough of 3D Printed Bioactive Implants

2025-09-18

Author: Siti

A Game-Changer in Bone Implant Technology

In a groundbreaking study published in Biomedical Technology, researchers have unveiled a revolutionary approach to 3D printing that could completely change how surgeons repair damaged bones. This innovative method combines advanced ink composition with strategic printing designs to create strong, bioactive bone implants that encourage natural healing.

The Secret Ingredients Behind Stronger Implants

The study highlights the use of direct ink writing, a technique that operates at room temperature, allowing for the creation of dense and stable implants, unlike traditional 3D-printed scaffolds which tend to be brittle and porous. Lead author Hongyi Chen from University College London points out a surprising twist: by printing the implants at 90-degree angles, the strength significantly improved due to more effective filament bonding.

Boosting Bioactivity with Nanotechnology

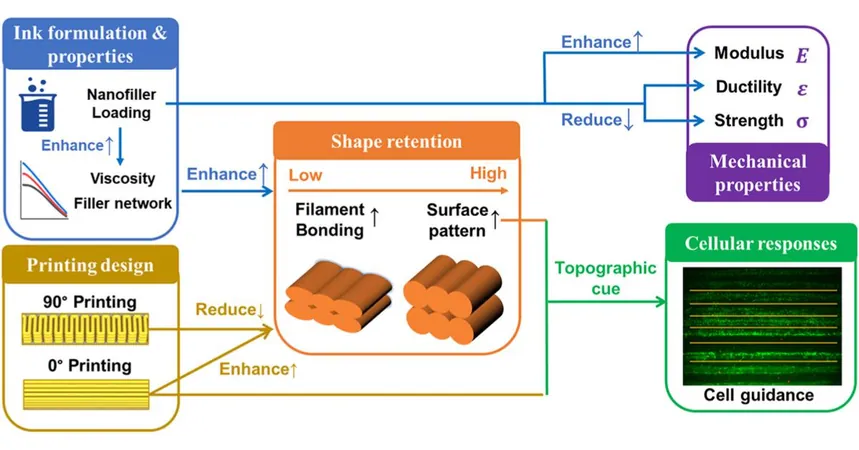

To further enhance the implants, researchers incorporated tiny particles of Laponite, a nanoclay, into the printing ink. These particles not only thickened the ink for improved shape retention but also released bioactive ions, promoting bone cell attachment and growth. The results were impressive—implants with higher Laponite content showed a 110% increase in stiffness and enhanced cell proliferation and mineralization.

Interconnected Design Choices Yield Better Outcomes

What sets this study apart is its comprehensive approach. Rather than isolating factors, the researchers examined the interplay of ink composition, printing orientation, structural mechanics, and cell responses. This holistic view allowed them to understand how each design decision impacts the biological performance of the implants.

Future Prospects: Custom Implants Ready When You Need Them

The implications of this research are vast, especially for fields like craniomaxillofacial reconstruction and dental grafting. Next steps involve exploring more intricate porous designs and testing the implants in preclinical models. If all goes well, this technology could lead to patient-specific implants that can be produced swiftly in hospital settings or even at the point of care.

Brasil (PT)

Brasil (PT)

Canada (EN)

Canada (EN)

Chile (ES)

Chile (ES)

Česko (CS)

Česko (CS)

대한민국 (KO)

대한민국 (KO)

España (ES)

España (ES)

France (FR)

France (FR)

Hong Kong (EN)

Hong Kong (EN)

Italia (IT)

Italia (IT)

日本 (JA)

日本 (JA)

Magyarország (HU)

Magyarország (HU)

Norge (NO)

Norge (NO)

Polska (PL)

Polska (PL)

Schweiz (DE)

Schweiz (DE)

Singapore (EN)

Singapore (EN)

Sverige (SV)

Sverige (SV)

Suomi (FI)

Suomi (FI)

Türkiye (TR)

Türkiye (TR)

الإمارات العربية المتحدة (AR)

الإمارات العربية المتحدة (AR)