Revolutionary "Zeolite Blending" Technique Breaks Barriers in Catalyst Development!

2025-03-27

Author: Rajesh

Introduction

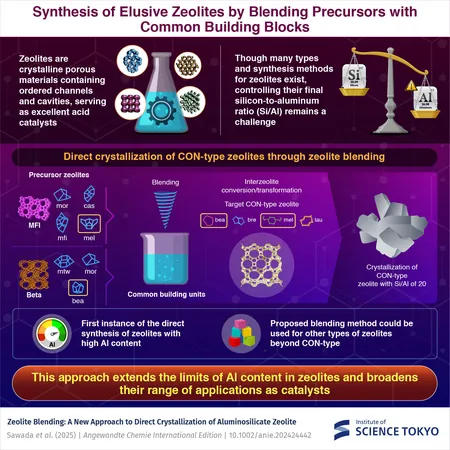

In a groundbreaking study, researchers from the Institute of Science Tokyo have unveiled an innovative "zeolite blending" technique that has achieved the synthesis of CON-type zeolites with previously unattainable high aluminum content. This cutting-edge approach not only addresses enduring challenges in controlling aluminum levels within zeolite frameworks but also promises to revolutionize catalyst development for a diverse range of industrial applications, spanning petrochemical processing, fine chemicals manufacturing, and environmental cleanup initiatives.

What Are Zeolites?

Zeolites are crystalline, porous materials renowned for their ordered channels and cavities, which make them highly effective catalysts in numerous industrial processes. A key attribute of zeolites lies in their acidic sites, created when aluminum (Al) atoms are integrated into their silica matrix. The aluminum content is crucial, as it directly affects both the acidity and catalytic properties of the zeolite, necessitating precise control for optimal performance.

The Challenge of Aluminum Control

Despite extensive research efforts over the past few decades, attaining sufficient control over aluminum content—especially in CON-type zeolites—has remained a daunting challenge for scientists. Traditionally, achieving a silicon-to-aluminum (Si/Al) ratio lower than 100 through direct synthesis methods has proven elusive.

Breakthrough in Zeolite Synthesis

However, a recent publication in *Angewandte Chemie International Edition* highlights the accomplishment of Professor Toshiyuki Yokoi and his team, who have developed a novel synthesis method known as "zeolite blending." This technique involves combining various zeolite precursors to steer the crystallization process, enabling the production of high-Al CON-type zeolites with a Si/Al ratio of approximately 20—an unprecedented achievement in global research.

Initial Findings

Initially, the researchers employed single zeolite precursors to create CON-type zeolites with a Si/Al ratio around 40, marking a significant improvement over traditional methods. The true breakthrough became evident when they strategically blended multiple zeolite types during the synthesis process. They found that combining Beta zeolite with small quantities of MFI-type zeolite all but guaranteed the formation of high-aluminum CON-type structures.

Expert Quote

"This strategy has allowed us to synthesize CON-type zeolites with a Si/Al ratio of approximately 20, which was previously unachievable with a singular precursor. This accomplishment marks the first direct synthesis of zeolites with such a high aluminum content worldwide," stated Professor Yokoi.

Enhanced Properties of New Zeolites

The newly synthesized high-Al CON-type zeolites exhibited enhanced properties when compared to those created using conventional post-treatment methods, boasting smaller particle sizes and more even aluminum distribution. These enhancements make them particularly valuable for catalytic applications, notably in the methanol-to-olefin process—a crucial step in producing high-demand petrochemicals from alternative feedstocks.

Future Implications

Moreover, the implications of this novel zeolite blending technique extend beyond the immediate success with CON-type zeolites. This methodology opens doors to a broader range of zeolite structures with previously unreachable compositions. Professor Yokoi further emphasized, "We are currently examining the physicochemical properties of the starting materials and their specific roles, deepening our understanding of this blending method."

Conclusion

With the introduction of the zeolite blending technique, the landscape of catalyst development is set to transform, paving the way for cleaner fuels and greener industries that can efficiently meet global demands. Stay tuned as this pioneering research unfolds with more exciting developments on the horizon!

Brasil (PT)

Brasil (PT)

Canada (EN)

Canada (EN)

Chile (ES)

Chile (ES)

Česko (CS)

Česko (CS)

대한민국 (KO)

대한민국 (KO)

España (ES)

España (ES)

France (FR)

France (FR)

Hong Kong (EN)

Hong Kong (EN)

Italia (IT)

Italia (IT)

日本 (JA)

日本 (JA)

Magyarország (HU)

Magyarország (HU)

Norge (NO)

Norge (NO)

Polska (PL)

Polska (PL)

Schweiz (DE)

Schweiz (DE)

Singapore (EN)

Singapore (EN)

Sverige (SV)

Sverige (SV)

Suomi (FI)

Suomi (FI)

Türkiye (TR)

Türkiye (TR)

الإمارات العربية المتحدة (AR)

الإمارات العربية المتحدة (AR)