Revolutionary Sponge Made from Graphene Oxide and Chitosan Could Change E-Waste Recycling Forever!

2024-10-26

Author: Wei

Introduction

A groundbreaking innovation from a collaborative team of chemists and materials scientists at the National University of Singapore, alongside experts from Manchester University in the U.K. and Guangdong University of Technology in China, has unveiled a highly effective sponge composed of graphene oxide and chitosan, designed to extract gold from electronic waste—potentially transforming the recycling industry.

Research Study Details

In a recent study published in the Proceedings of the National Academy of Sciences, the research team detailed their novel sponge's creation and its impressive testing outcomes. Traditionally, the process of extracting valuable metals like gold and silver from discarded electronic devices has proven to be both labor-intensive and environmentally hazardous, releasing harmful pollutants while often yielding low results.

Breakthrough Sponge Technology

However, this new sponge technology represents a significant leap forward, achieving gold extraction in a manner that is both cost-effective and eco-friendly. The team opted for their materials due to their historical success in metal extraction. Graphene is renowned for its ion-absorbing properties, while chitosan—a natural biopolymer sourced from shellfish—serves as a powerful reducing agent. This combination catalytically transforms gold ions into solid gold, streamlining the overall process.

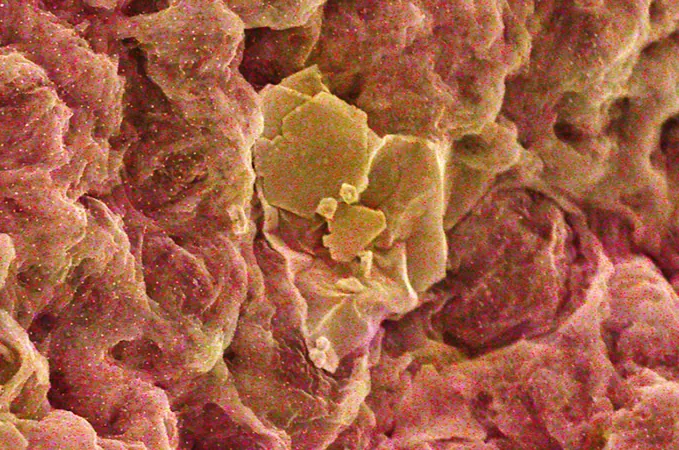

Sponge Creation Method

The innovative sponge is created by enabling chitosan to self-assemble onto two-dimensional graphene flakes. This method not only integrates the two materials but also creates specific sites on the sponge for binding gold ions. Once the gold ions are absorbed, the chitosan converts them into a solid form, making collection straightforward and highly efficient.

Testing with Real E-Waste

In practical applications, the team tested the sponge using actual electronic waste from a recycling company. The e-waste was processed into a solution containing a mixture of materials from various devices. Initial measurements indicated gold concentrations of 3 parts per million (ppm).

Extraction Efficiency

Impressively, their advanced sponge was able to extract around 17 grams of Au³⁺ ions and more than 6 grams of Au⁺ ions per gram of sponge material. This extraordinary performance equates to an extraction efficiency approximately ten times greater than any previously known method.

Environmental Implications

This innovative approach to recovering precious metals not only has potential commercial implications but also promises to reduce environmental impact associated with electronic waste disposal. As the world faces rising e-waste challenges, solutions like this sponge may pave the way for sustainable recycling practices capable of reclaiming valuable resources while minimizing harm to the planet.

Conclusion

Stay tuned, as this development could revolutionize the gold recovery process, making electronic waste recycling not only smarter but significantly greener!

Brasil (PT)

Brasil (PT)

Canada (EN)

Canada (EN)

Chile (ES)

Chile (ES)

España (ES)

España (ES)

France (FR)

France (FR)

Hong Kong (EN)

Hong Kong (EN)

Italia (IT)

Italia (IT)

日本 (JA)

日本 (JA)

Magyarország (HU)

Magyarország (HU)

Norge (NO)

Norge (NO)

Polska (PL)

Polska (PL)

Schweiz (DE)

Schweiz (DE)

Singapore (EN)

Singapore (EN)

Sverige (SV)

Sverige (SV)

Suomi (FI)

Suomi (FI)

Türkiye (TR)

Türkiye (TR)