Revolutionary Solar-Powered Technology Converts Waste Into Valuable Chemicals, Slashing Carbon Emissions!

2025-03-28

Author: Nur

Groundbreaking Development in Solar-Powered Technology

In a groundbreaking development, researchers from the Ulsan National Institute of Science and Technology (UNIST) have unveiled an innovative solar-powered system capable of producing ammonia and glycolic acid—two vital industrial chemicals—by harnessing the power of sunlight while eliminating harmful carbon dioxide emissions. This remarkable advancement could signal a transformative shift in how we address pollution and energy sustainability.

Research Insights and Methodology

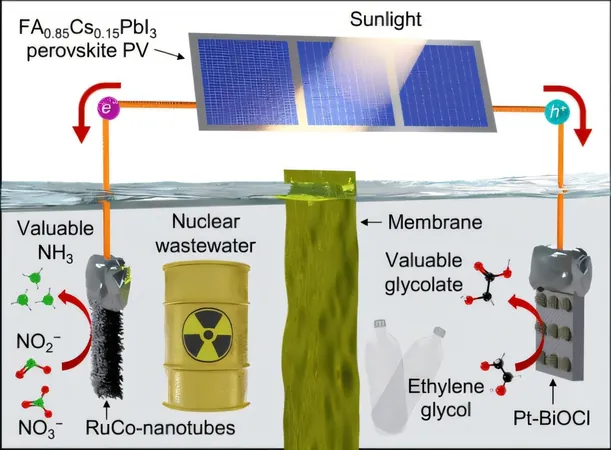

The research, led by Professors Seungho Cho and Myoung Hoon Song from the Department of Materials Science and Engineering at UNIST, focuses on harnessing solar energy to drive electrochemical reactions that convert nitrate pollutants in wastewater into ammonia. Simultaneously, this process transforms plastic waste into glycolic acid, a key ingredient widely used in cosmetic products. By turning waste materials into valuable resources, this technology presents a dual benefit of resource recovery and environmental remediation.

The Need for Sustainable Practices

Published in the prestigious journal *Nano Letters*, the findings shed light on the pressing need for sustainable practices in chemical production. Currently, the Haber-Bosch process, the conventional method of producing ammonia, contributes to approximately 1.4% of global carbon dioxide emissions. This alarming statistic highlights the urgency for cleaner, more efficient alternatives.

Innovative System and Efficiency Achievements

The innovative system combines photovoltaic technology with electrocatalysis, enabling ammonia production at the cathode and glycolic acid generation at the anode—all powered by solar energy. The researchers cleverly utilize nitrite (NO2-) from wastewater, reducing the energy and time required compared to conventional nitrate input, thereby optimizing the overall efficiency of the process.

Remarkably, the system has achieved an impressive energy efficiency of 52.3%, setting a new record for anode performance alone. The ammonia production rate soared to 146 μmol/cm²h, far surpassing the U.S. Department of Energy's commercialization benchmark of 58.72 μmol/cm²h, representing a 46% improvement over previous technologies.

Catalyst Development and System Performance

A key element of the system's success is the development of an advanced catalyst known as RuCo-NT/CF, which selectively reduces nitrite and minimizes energy loss from less efficient reactions. This targeted approach ensures an effective and streamlined process, directly addressing global sustainability goals.

Future Prospects and Implications

The researchers equipped their system with a perovskite solar cell, known for its exceptional electrical output and durability. As the intensity of the photovoltaic current increases, so does the rate of ammonia synthesis, allowing for rapid scaling of production.

Professor Song emphasized the implications of their work, stating, "This research highlights the immense potential for carbon-dioxide-free electrochemical ammonia production using perovskite solar cells, which deliver superior performance compared to traditional silicon solar cells."

Commercial Viability and Conclusion

The team is now evaluating the commercial viability of their technology, forecasting a solar ammonia production rate of 114 μmol/cm²h when using an electrolyte that mimics low-level radioactive wastewater and incorporates recycled PET materials.

In conclusion, this pioneering study not only paves the way for a sustainable, carbon-neutral energy solution but also offers a practical approach to combating plastic waste. As stated by Professor Cho, "Our research signifies a transformative step towards a greener future, combining sunlight and waste to produce green ammonia and glycolic acid—two critical components for various industries." This revolutionary system could spell out a brighter, cleaner future for chemical production worldwide.

Brasil (PT)

Brasil (PT)

Canada (EN)

Canada (EN)

Chile (ES)

Chile (ES)

Česko (CS)

Česko (CS)

대한민국 (KO)

대한민국 (KO)

España (ES)

España (ES)

France (FR)

France (FR)

Hong Kong (EN)

Hong Kong (EN)

Italia (IT)

Italia (IT)

日本 (JA)

日本 (JA)

Magyarország (HU)

Magyarország (HU)

Norge (NO)

Norge (NO)

Polska (PL)

Polska (PL)

Schweiz (DE)

Schweiz (DE)

Singapore (EN)

Singapore (EN)

Sverige (SV)

Sverige (SV)

Suomi (FI)

Suomi (FI)

Türkiye (TR)

Türkiye (TR)

الإمارات العربية المتحدة (AR)

الإمارات العربية المتحدة (AR)