Revolutionary Ru Catalyst Set to Transform Sustainable Hydrogen Production!

2025-03-24

Author: Nur

Revolutionary Ru Catalyst Set to Transform Sustainable Hydrogen Production!

In a groundbreaking advancement for sustainable energy, researchers from Seoul National University (SNU), led by Professor Jin Young Kim, have unveiled a new ruthenium-based catalyst that promises to redefine hydrogen production. Collaborating with Professor Chan Woo Lee from Kookmin University and Dr. Sung Jong Yoo from the Korea Institute of Science and Technology (KIST), this team has achieved what they describe as a monumental breakthrough in the field of hydrogen energy.

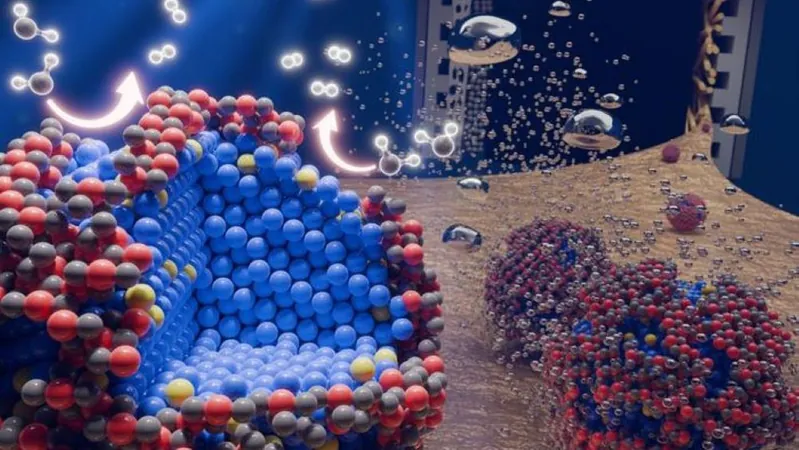

Their findings, published in the prestigious Energy & Environmental Science, highlight a ruthenium (Ru) core-shell nanocluster catalyst that boasts exceptional performance while using a mere fraction of precious metals. This innovative structure not only demonstrates 'world-class performance' but also unbelievable stability when employed in industrial-grade water electrolysis processes.

As the demand for hydrogen grows due to its potential in clean energy solutions, Anion Exchange Membrane Water Electrolysis (AEMWE) is emerging as a frontrunner technology. However, AEMWE has historically struggled due to the need for highly efficient and durable catalysts to ensure its commercial viability. Platinum, the reigning champion of hydrogen catalysts, is plagued by high costs and rapid wear, prompting researchers to seek viable alternatives. Many non-precious metals have been tested but often fail to achieve the required efficiency and longevity.

Enter the novel ruthenium core-shell catalyst, demonstrating more than double the cost efficiency compared to platinum. This revolutionary catalyst, reduced to less than 2nm in size, utilizes only one-third of precious metal yet provides 4.4 times the performance of traditional platinum catalysts at equal metal content. The breakthrough is described as having the highest ever recorded efficiency among hydrogen evolution catalysts, paired with a unique foam electrode structure that optimally supplies reactive materials while maintaining stability at high current densities.

In groundbreaking industrial tests, the new catalyst proved to require less energy than existing platinum catalysts, suggesting a significant leap forward in hydrogen production efficiency. The team's meticulous development process began with treating a titanium foam substrate with hydrogen peroxide to create a thin titanium oxide layer, followed by doping with molybdenum, ultimately leading to uniformly deposited ruthenium oxide nanoparticles.

Through advanced low-temperature thermal treatment, they achieved an atomic-level diffusion that formed the innovative core-shell structure. During hydrogen production, an electrochemical reduction process enhanced the properties of the catalyst, resulting in a ruthenium metal core enveloped by a porous reduced titania layer and metallic molybdenum atoms intermixed at the interface.

With the fusion of high performance and affordability, this catalyst opens doors for diverse applications—from hydrogen fuel cells powering electric vehicles to eco-friendly public transportation systems and hydrogen power plants. Professor Jin Young Kim emphasized the significance of this development, stating, “This breakthrough will pave the way for advancements in nano core-shell device technology and hydrogen production, bringing us a step closer to achieving a carbon-neutral future.”

Stay tuned as this innovative catalyst potentially revolutionizes the landscape of sustainable energy and hydrogen technology!

Brasil (PT)

Brasil (PT)

Canada (EN)

Canada (EN)

Chile (ES)

Chile (ES)

Česko (CS)

Česko (CS)

대한민국 (KO)

대한민국 (KO)

España (ES)

España (ES)

France (FR)

France (FR)

Hong Kong (EN)

Hong Kong (EN)

Italia (IT)

Italia (IT)

日本 (JA)

日本 (JA)

Magyarország (HU)

Magyarország (HU)

Norge (NO)

Norge (NO)

Polska (PL)

Polska (PL)

Schweiz (DE)

Schweiz (DE)

Singapore (EN)

Singapore (EN)

Sverige (SV)

Sverige (SV)

Suomi (FI)

Suomi (FI)

Türkiye (TR)

Türkiye (TR)

الإمارات العربية المتحدة (AR)

الإمارات العربية المتحدة (AR)