Revolutionary Plasma Simulations Set to Transform Chip Manufacturing

2025-05-21

Author: Rajesh

In the fascinating realm of chip manufacturing, plasma—the electrically charged fourth state of matter—plays a pivotal role. However, creating efficient simulations of this vital substance has long posed a challenge: the need for lightning-fast calculations while ensuring accuracy.

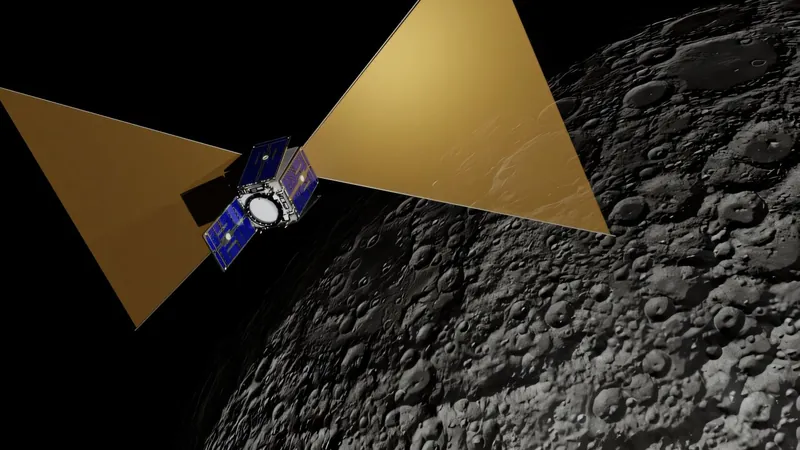

Researchers have recently struck gold with a groundbreaking method that enhances the speed and reliability of kinetic simulations. Developed through an innovative partnership between the U.S. Department of Energy's Princeton Plasma Physics Laboratory (PPPL) and chip equipment giant Applied Materials, this powerful tool is already being utilized to refine manufacturing processes.

Understanding plasmas at a granular level is critical for improving the techniques used to etch intricate patterns on silicon—essential for creating faster chips and larger memory storage. Igor Kaganovich, a leading research physicist at PPPL, emphasizes the importance, stating, "This is a big step forward in our capabilities."

From Unreliable to Unstoppable: A Major Code Overhaul

The initial simulation code faced reliability issues, relying on outdated methodologies. Dmytro Sydorenko, a research associate at the University of Alberta, led a substantial reworking of the existing approach to eliminate crashes and enhance stability. "We changed the equations, so the simulation immediately became very reliable and there were no crashes anymore," he explained.

The modifications focused on how an essential electric field, specifically the solenoidal electric field generated by a wire coil's magnetic current, was calculated. This field is crucial as it heats the plasma for various applications, making the improvements particularly impactful.

An Innovative Approach to Energy Conservation

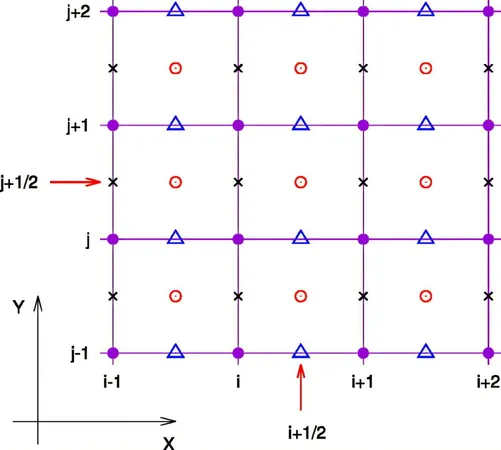

The enhanced simulation—known as a particle-in-cell code—tracks the movement of individual particles, which is particularly advantageous for industrial plasmas operating at low gas pressures. By ensuring accurate energy conservation, researchers can obtain results that reflect real-world physics rather than mere numerical artifacts.

Optimizing this simulation was a collaborative effort, with a team of experts from PPPL, the University of Alberta, and the Los Alamos National Laboratory working together seamlessly. Salomon Janhunen’s procedures were fine-tuned by PPPL's Jin Chen, who played a crucial role in harmonizing physics, mathematics, and computer science.

This enhanced capability for rapid and reliable plasma simulation heralds a new era for chip manufacturing, paving the way for more sophisticated and efficient technologies that could redefine our digital future.

Brasil (PT)

Brasil (PT)

Canada (EN)

Canada (EN)

Chile (ES)

Chile (ES)

Česko (CS)

Česko (CS)

대한민국 (KO)

대한민국 (KO)

España (ES)

España (ES)

France (FR)

France (FR)

Hong Kong (EN)

Hong Kong (EN)

Italia (IT)

Italia (IT)

日本 (JA)

日本 (JA)

Magyarország (HU)

Magyarország (HU)

Norge (NO)

Norge (NO)

Polska (PL)

Polska (PL)

Schweiz (DE)

Schweiz (DE)

Singapore (EN)

Singapore (EN)

Sverige (SV)

Sverige (SV)

Suomi (FI)

Suomi (FI)

Türkiye (TR)

Türkiye (TR)

الإمارات العربية المتحدة (AR)

الإمارات العربية المتحدة (AR)