Revolutionary New Synthetic Material Mimics Nature for Enhanced Protection!

2025-05-16

Author: Li

Unlocking Nature’s Secrets for Safer Innovations

In a groundbreaking study, engineers have successfully harnessed the power of layered synthetic materials to create innovative protective solutions modeled after nature. Inspired by the remarkable design of marine creatures like mollusks, which have evolved to build complex, multi-layered shells that distribute physical stress, researchers are now mimicking this behavior to develop advanced materials. These new synthetic structures promise to revolutionize energy-absorbing applications, from wearable technology to automotive safety.

Collaborating Layers for Maximum Impact

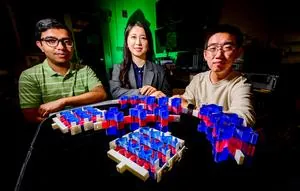

Led by Professor Shelly Zhang from the University of Illinois Urbana-Champaign and Professor Ole Sigmund from the Technical University of Denmark, the team has developed a framework for programmable multilayered materials. These materials can respond intelligently to stress thanks to their intricate microscale interconnections.

"We realized that existing materials reach a physical limit in terms of their mechanical responses. This led us to explore how engineered layers could better replicate extreme behaviors seen in biological systems, like the energy-dissipating capabilities of car bumpers," Zhang explained.

A Game-Changer in Material Design

This innovative framework allows individual layers to possess distinct properties and to collaborate effectively, enhancing the overall performance. Unlike existing methods that focus on single-layer systems, this multilayered approach significantly broadens design possibilities.

Zhang noted, "Our new methodology not only optimizes properties akin to the natural material nacre but also creates internal connections that improve mechanical response, making it far more versatile than any previous models."

Navigating Real-World Challenges

While this research has opened doors to exciting new material capabilities, the team also faced challenges in translating theoretical concepts into practical applications. The material must be fabricated in finite units, which led to discrepancies between expected and actual performance.

Zhang observed, "These differences are typical in real-world scenarios, yet they provide invaluable data for refining our processes. By decoding the performance variations, we can program our materials to exhibit desired behaviors, enhancing their functionality even further."

Collaboration is Key

The findings underscore a fundamental principle: collaboration leads to greater innovations. As Zhang concluded, "Just as diverse materials can work together to achieve remarkable outcomes, our study demonstrates that interdisciplinary collaboration can drive significant advancements in material science."

Future Excitement Awaits!

Although there’s more to be done to scale production for these advanced materials, the potential implications for safety and protection in various fields are immense. The journey of discovery continues, but one thing is clear: by working together, whether it’s materials or researchers, we can create solutions that are truly transformative.

Brasil (PT)

Brasil (PT)

Canada (EN)

Canada (EN)

Chile (ES)

Chile (ES)

Česko (CS)

Česko (CS)

대한민국 (KO)

대한민국 (KO)

España (ES)

España (ES)

France (FR)

France (FR)

Hong Kong (EN)

Hong Kong (EN)

Italia (IT)

Italia (IT)

日本 (JA)

日本 (JA)

Magyarország (HU)

Magyarország (HU)

Norge (NO)

Norge (NO)

Polska (PL)

Polska (PL)

Schweiz (DE)

Schweiz (DE)

Singapore (EN)

Singapore (EN)

Sverige (SV)

Sverige (SV)

Suomi (FI)

Suomi (FI)

Türkiye (TR)

Türkiye (TR)

الإمارات العربية المتحدة (AR)

الإمارات العربية المتحدة (AR)