Revolutionary Model Could Transform Our Understanding of Material Hardness!

2025-01-16

Author: Mei

Introduction

In a groundbreaking study, researchers at Skoltech have introduced a straightforward physical model designed to predict the hardness of materials, leveraging key information about shear modulus alongside state equations for crystal structures. This innovative approach holds significant promise for diverse real-world applications, as all parameters utilized in the model can either be calculated or measured with relative ease.

Published Findings

The findings are detailed in the respected journal, *Physical Review Materials*.

Importance of Hardness

Hardness, a critical characteristic of materials, dictates their capacity to resist deformation and handle damage from external forces—whether from dents or scratches. Conventionally, assessing hardness involves pressing a harder indenter, most often made of diamond, into the test sample. The measurement is based on the maximum force applied during indentation versus the resulting impression left on the material.

Industry Demand for Advanced Materials

Modern industries are on the lookout for new hard and superhard materials boasting enhanced mechanical properties, which surpass those of traditional options. With this in mind, the research highlights the necessity for innovative computational methodologies that facilitate high-throughput screening to identify materials with improved characteristics.

Advancements in Computational Techniques

Ph.D. student Faridun Jalolov, the study's lead author from the Materials Science and Engineering program at Skoltech, emphasized the advancements in computational techniques: "Today, the capabilities of computational methods allow us to accurately predict both the structure and properties of numerous materials. Yet, it is crucial not only to forecast the material's architecture but also to precisely evaluate mechanical properties like hardness, which are essential for creating materials with desired specifications through experimental synthesis."

Simplified Approach

While prior empirical models for predicting hardness focused on factors like the strength of chemical bonds and material electronegativity, the new model simplifies the equation by concentrating on the shear modulus and the pressure derivative of the bulk modulus. Both of these vital properties can be readily acquired through experimental processes or atomistic simulations.

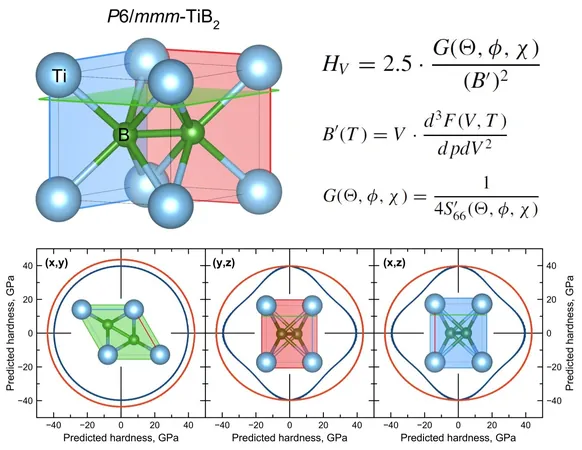

Role of Shear Modulus

The shear modulus plays a pivotal role in determining hardness due to its reliance on the deformation direction of the crystal structure, allowing researchers to calculate the spatial distribution of hardness by accounting for the anisotropy, or directional dependence, present in different materials. By integrating the pressure derivative of the bulk modulus derived from the equation of state, the research team further considered the influence of temperature on material hardness.

Future Implications

As industries brace for a surge in demand for tougher materials capable of withstanding significant wear and tear, this new model could be a game-changer—opening doors to the development of advanced materials with applications in fields ranging from aerospace engineering to construction and beyond. Stay tuned as this research could reshape material science as we know it!

Brasil (PT)

Brasil (PT)

Canada (EN)

Canada (EN)

Chile (ES)

Chile (ES)

Česko (CS)

Česko (CS)

대한민국 (KO)

대한민국 (KO)

España (ES)

España (ES)

France (FR)

France (FR)

Hong Kong (EN)

Hong Kong (EN)

Italia (IT)

Italia (IT)

日本 (JA)

日本 (JA)

Magyarország (HU)

Magyarország (HU)

Norge (NO)

Norge (NO)

Polska (PL)

Polska (PL)

Schweiz (DE)

Schweiz (DE)

Singapore (EN)

Singapore (EN)

Sverige (SV)

Sverige (SV)

Suomi (FI)

Suomi (FI)

Türkiye (TR)

Türkiye (TR)

الإمارات العربية المتحدة (AR)

الإمارات العربية المتحدة (AR)