Revolutionary Light-Based Polymerization Technique Transforms 3D Printing with Unmatched Precision!

2025-03-26

Author: Wei Ling

Introduction

A groundbreaking innovation by researchers at the Universitat Autònoma de Barcelona (UAB) has harnessed the power of light in a revolutionary chemical reaction to create solid polymer networks with unparalleled precision—allowing for the fabrication of materials with resolutions surpassing one-thousandth of a millimeter. This research paves the way for advanced lithographic methods and next-generation 3D printing techniques.

The Limitations of Conventional 3D Printing

In a world where 3D printing is becoming ubiquitous, conventional approaches often struggle with significant limitations such as prolonged printing times and inadequate resolution, which hinder the ability to produce items at a micrometric scale. Traditional methods typically involve either extruding pre-made polymer materials or generating them in real time from monomers. Yet, these strategies frequently lead to subpar results in precision and efficiency.

Introduction of Photopolymerization

Enter the innovative solution of photopolymerization—a process that utilizes light to accelerate polymer formation. This method allows for faster production rates and offers precise control over spatial and temporal factors. Existing processes primarily depend on a single light source, often leading to challenges such as unwanted diffusion of reagents beyond the illuminated area or extended reaction lifetimes that compromise spatiotemporal resolution. Furthermore, conventional optical techniques are restricted by diffraction limits, leaving many aspiring designs unrealized at nanometric scales.

Collaborative Research and Breakthroughs

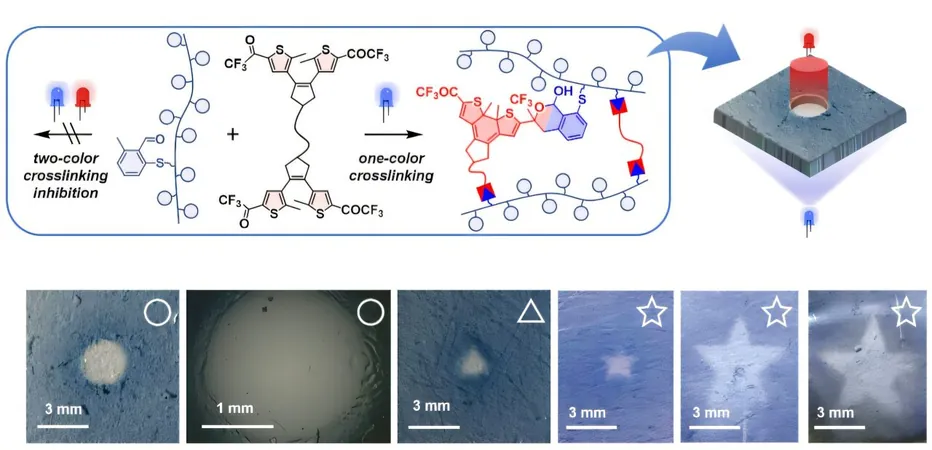

To tackle these hurdles, UAB researchers, spearheaded by Jordi Hernando, collaborated with Professor Christopher Barner-Kowollik’s team at Queensland University of Technology in Australia. Together, they pioneered a cutting-edge photopolymerization reaction that harnesses two distinct light wavelengths to control polymerization: one light source fosters material formation, while the other acts to inhibit it.

The Dual-Light Strategy

Detailed in their recent publication in Advanced Functional Materials, the breakthrough employs a novel photoinduced curing method based on an oxo-Diels–Alder cycloaddition between two reactants. According to Hernando, “We use prepolymers activated by ultraviolet (UV) light, alongside curing agents that toggle between reactive and non-reactive states based on the type of light they are exposed to—UV or red light.”

Conclusion and Future Directions

This dual-light strategy culminates in distinctly patterned irradiation zones, enabling polymer resin curing only in regions exclusively illuminated by UV light. Crucially, in areas exposed to both light types, no solid polymer forms, allowing for the meticulous design of polymeric shapes with sub-millimeter resolution. Looking ahead, Hernando emphasizes their ambitions to refine this innovative process further to achieve stunning sub-micrometer resolutions in 3D printing, marking a significant leap forward for this technology—potentially revolutionizing not only manufacturing but also industries as diverse as biomedicine, aerospace, and electronics.

Stay tuned for a potential future where 3D printed materials reach unprecedented levels of detail and function, all thanks to the revelatory interplay of light and chemistry!

Brasil (PT)

Brasil (PT)

Canada (EN)

Canada (EN)

Chile (ES)

Chile (ES)

Česko (CS)

Česko (CS)

대한민국 (KO)

대한민국 (KO)

España (ES)

España (ES)

France (FR)

France (FR)

Hong Kong (EN)

Hong Kong (EN)

Italia (IT)

Italia (IT)

日本 (JA)

日本 (JA)

Magyarország (HU)

Magyarország (HU)

Norge (NO)

Norge (NO)

Polska (PL)

Polska (PL)

Schweiz (DE)

Schweiz (DE)

Singapore (EN)

Singapore (EN)

Sverige (SV)

Sverige (SV)

Suomi (FI)

Suomi (FI)

Türkiye (TR)

Türkiye (TR)

الإمارات العربية المتحدة (AR)

الإمارات العربية المتحدة (AR)