Revolutionary Electron Beam Technique Unleashes Precision Nanoscale Crafting of Copper Structures

2025-07-25

Author: Yu

Engineers Tackle Nanoscale Challenges with New Method

Crafting intricate structures at nanoscale has long eluded engineers, but a groundbreaking study from Georgia Tech reveals how electron beams, traditionally used for imaging and fabrication, can now serve as ultra-precise sculpting instruments for materials like copper.

A Game-Changer in Nanoscale Manufacturing

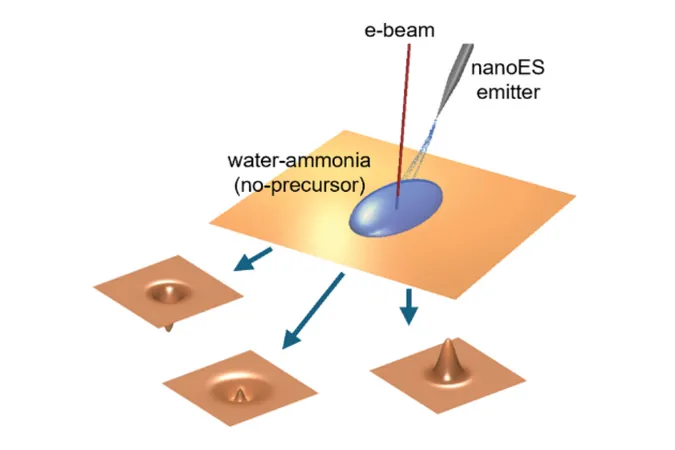

Led by Professor Andrei Fedorov at the George W. Woodruff School of Mechanical Engineering, researchers have unveiled a method utilizing focused electron beams in a liquid environment. This innovative approach allows them to either carve or construct copper structures based on the surrounding chemistry—a true leap forward in nanoscale engineering.

Dynamic Sculpting at the Atomic Level

By adjusting ammonia levels in the solution, the team was able to control the electron beam's behavior, toggling between etching and depositing copper. With minimal ammonia, the beam etched out ultra-narrow trenches just 50 nanometers deep—impressively 2,000 times thinner than a sheet of paper!

Mastering Material Transformation

As copper was etched away, atoms began to refill these trenches, creating tiny vertical formations resembling peaks in valleys. Depending on the electron exposure time, the size and complexity of these patterns could be meticulously controlled.

The Ammonia Advantage

The researchers identified ammonia as a pivotal player, enabling detailed manipulation of the copper structure. Auwais Ahmed, lead author and Ph.D. candidate, explained:

"Ammonia facilitates the movement of copper atoms, prevents undesirable reactions, and shifts the environment toward building rather than etching." With precision adjustments, the team achieved nanometer-level craftsmanship.

Flipping Between Etching and Building in Real Time

Fedorov emphasized the excitement of their findings, stating, "We're not just additive or subtractive; we're seamlessly switching between these modes in real time!"

Brasil (PT)

Brasil (PT)

Canada (EN)

Canada (EN)

Chile (ES)

Chile (ES)

Česko (CS)

Česko (CS)

대한민국 (KO)

대한민국 (KO)

España (ES)

España (ES)

France (FR)

France (FR)

Hong Kong (EN)

Hong Kong (EN)

Italia (IT)

Italia (IT)

日本 (JA)

日本 (JA)

Magyarország (HU)

Magyarország (HU)

Norge (NO)

Norge (NO)

Polska (PL)

Polska (PL)

Schweiz (DE)

Schweiz (DE)

Singapore (EN)

Singapore (EN)

Sverige (SV)

Sverige (SV)

Suomi (FI)

Suomi (FI)

Türkiye (TR)

Türkiye (TR)

الإمارات العربية المتحدة (AR)

الإمارات العربية المتحدة (AR)