Revolutionary Discovery: How Alternating Current Can Slash Friction and Boost Longevity in Materials!

2025-07-09

Author: Sarah

Introducing a Game-Changing Technique Against Friction

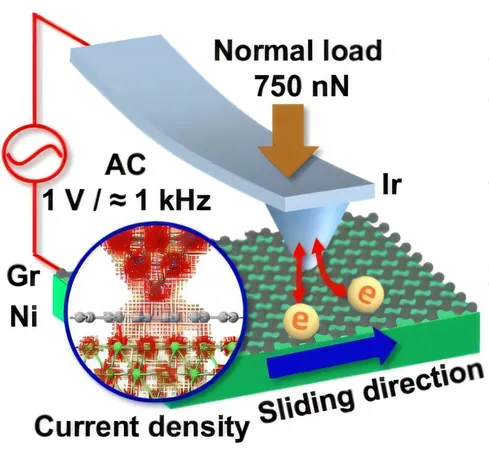

A groundbreaking research team, spearheaded by Prof. Tian-Bao Ma from Tsinghua University’s Department of Mechanical Engineering, has unveiled a revolutionary strategy to dramatically reduce friction and wear in materials. By harnessing the power of alternating electric current (AC), they've discovered a way to induce dynamic changes in electronic density at material interfaces.

Friction? Not Anymore!

Imagine altering the friction of materials with just an electric current! This innovative method allows scientists to instantly modulate friction levels by tweaking the amplitude and frequency of the applied AC. Even under intense pressure and high current densities, this approach maintains remarkably low friction and wear, all while operating on minimal voltage!

A Lengthy Lifespan for Materials

Published in the esteemed journal Nature Communications, the findings reveal that this technique can sustain low friction for over 70,000 seconds at contact pressures up to 9.1 GPa, with no sign of wear. That’s impressive!

Friction Reduction Unlocked!

Historically, reducing friction has been a relentless quest—an endeavor now made simpler with atomic-level insights. While researchers have previously succeeded in lowering friction by controlling interfacial atom arrangements, the role of electronic properties had gone largely unexplored. However, this study offers a fresh perspective!

Experimental Insights: A 75% Drop in Friction Force!

In striking experiments conducted with conductive atomic force microscopy (c-AFM), scientists found that applying AC at the right frequencies can slash frictional forces by approximately 75% between an Ir-coated AFM tip and graphene on a nickel substrate!

The Mechanics Behind the Magic!

Unlike traditional methods that rely on mechanical vibrations, the ideal frequency for friction reduction isn’t tied to system resonance but rather the unique washboard frequency. The minuscule electrostatic forces generated by the AC—about 1 nN—contrast sharply with the normal load, igniting a different friction reduction mechanism.

Breaking Down the Science: PTT-E Model

Delving deeper, researchers employed first-principles calculations to showcase that the dynamic redistribution of electronic density holds the key to lowered friction. By altering the electrostatic potential at the interface through an applied bias voltage, electron redistribution changes interfacial atomic forces—resulting in significantly reduced friction.

Exceptional Predictions and Broader Applications

The team’s PTT-E model demonstrated precise predictions regarding variations in friction relative to AC amplitude, frequency, and sliding velocity, aligning seamlessly with their experimental findings. Furthermore, this fascinating effect of electronic activation seems relevant across different 2D material-metal interfaces, paving the way for broader applications.

A Path to Enhanced MEMS/NEMS Performance

Prof. Ma asserts that this newly discovered mechanism for electrically activated friction reduction could serve as a solution to the longstanding challenge of wear in MEMS/NEMS under heavy mechanical loads. It’s a promising leap forward in enhancing the durability and efficiency of micro and nano-electromechanical systems!

Brasil (PT)

Brasil (PT)

Canada (EN)

Canada (EN)

Chile (ES)

Chile (ES)

Česko (CS)

Česko (CS)

대한민국 (KO)

대한민국 (KO)

España (ES)

España (ES)

France (FR)

France (FR)

Hong Kong (EN)

Hong Kong (EN)

Italia (IT)

Italia (IT)

日本 (JA)

日本 (JA)

Magyarország (HU)

Magyarország (HU)

Norge (NO)

Norge (NO)

Polska (PL)

Polska (PL)

Schweiz (DE)

Schweiz (DE)

Singapore (EN)

Singapore (EN)

Sverige (SV)

Sverige (SV)

Suomi (FI)

Suomi (FI)

Türkiye (TR)

Türkiye (TR)

الإمارات العربية المتحدة (AR)

الإمارات العربية المتحدة (AR)