Revolutionary Design Strategy Tackles Cracking in Next-Gen Battery Cathodes!

2025-05-12

Author: Rajesh

A Breakthrough in Battery Technology

A cutting-edge research team from UNIST, led by Professor Hyeon Jeong Lee, has made a groundbreaking discovery that could radically enhance the performance of next-generation batteries. They’ve pinpointed the root causes of damaging internal cracks in lithium nickel manganese oxide (LNMO) cathodes, which are pivotal for high-performance battery applications.

What Makes LNMO Cathodes So Special?

LNMO is rapidly becoming a go-to choice for battery manufacturers, thanks to its impressive operating voltage of 4.7V and its cost-effective chemical structure—void of pricey cobalt. These cathodes, particularly in their single-crystal form, promise batteries that not only boast greater energy density but also longer lifespans.

The Cracking Conundrum

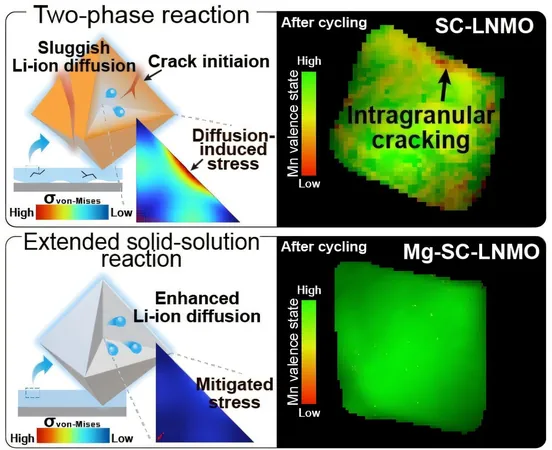

Unlike traditional polycrystalline cathodes made up of multiple grains, single-crystal cathodes maintain a uniform structure without grain boundaries, which typically helps reduce internal cracking. However, challenges still arise during high-rate charging and discharging, where internal stress can lead to cracks within the crystal—compromising performance.

What’s Causing the Cracks?

The team discovered that uneven lithium-ion diffusion within the crystal creates localized stress points. When this stress surpasses the crystal’s yield strength, cracks form—especially during demanding charge and discharge cycles.

Innovative Solution: Introducing Magnesium!

The researchers turned to magnesium, integrating it into the crystal lattice as a structural support. This clever addition stabilizes ion diffusion pathways, boosting lithium-ion mobility and significantly reducing internal strain. The result? Magnesium-doped single-crystal cathodes show remarkable durability under rapid cycling, drastically cutting down on crack formation.

Unveiling the Design Principles

By employing advanced continuum modeling, the team analyzed the link between lithium-ion diffusion rates and mechanical failure, paving the way for new design principles. These insights promise to create single-crystal cathodes that are not only mechanically robust but also reliable at high current densities.

The Future of High-Performance Batteries

Professor Lee emphasized, "This research sheds light on the mechanical degradation processes in single-crystal cathodes. By combining experimental and computational techniques, we’ve developed a strong design strategy that enhances structural integrity—an essential factor for the commercialization of next-gen batteries."

Leading the Charge

The research was spearheaded by Hyunsol Shin from the Department of Materials Science and Engineering at UNIST, marking a significant step forward in battery technology and promising exciting developments for the future.

Brasil (PT)

Brasil (PT)

Canada (EN)

Canada (EN)

Chile (ES)

Chile (ES)

Česko (CS)

Česko (CS)

대한민국 (KO)

대한민국 (KO)

España (ES)

España (ES)

France (FR)

France (FR)

Hong Kong (EN)

Hong Kong (EN)

Italia (IT)

Italia (IT)

日本 (JA)

日本 (JA)

Magyarország (HU)

Magyarország (HU)

Norge (NO)

Norge (NO)

Polska (PL)

Polska (PL)

Schweiz (DE)

Schweiz (DE)

Singapore (EN)

Singapore (EN)

Sverige (SV)

Sverige (SV)

Suomi (FI)

Suomi (FI)

Türkiye (TR)

Türkiye (TR)

الإمارات العربية المتحدة (AR)

الإمارات العربية المتحدة (AR)