Revolutionary Copper Plating Technique Dramatically Enhances TOPCon Solar Cell Performance!

2025-01-27

Author: Wei Ling

Introduction

Scientists at the University of New South Wales (UNSW) have made significant strides in solar technology by tackling a notorious problem: the degradation of tunnel oxide passivated contact (TOPCon) solar cells due to contaminants. Their innovative solution involves the application of copper (Cu) plating on screen-printed devices, which not only improves the durability and reliability of these solar cells but also holds the potential to minimize silver usage and subsequently reduce the levelised cost of electricity (LCOE).

Research Methodology

Lead researcher Bram Hoex revealed that their findings specifically address the vulnerability of TOPCon cells to corrosion, particularly in areas that contact the front metallization. "By introducing a 1 µm Cu plating layer on the front silver grid, we have created a protective barrier that significantly reduces susceptibility to corrosion," Hoex stated in a conversation with PV Magazine.

This groundbreaking research took a unique approach by conducting experiments at the cell level, rather than the module level. This allowed the team to accelerate their testing process by an impressive two orders of magnitude, leading to quicker results and a more profound failure analysis. This strategy has significantly improved the efficiency of their research and development cycle.

Cell Design and Plating Process

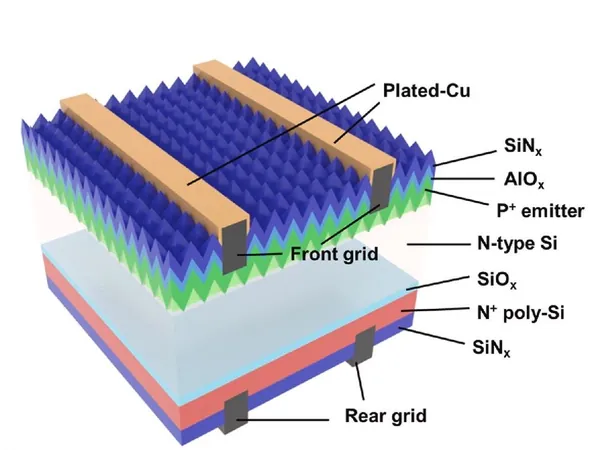

The researchers utilized bifacial nine-busbar (9BB) 158 mm TOPCon solar cells designed with carrier-selective passivating contacts (CSPCs) composed of polysilicon and silicon monoxide (poly-SiOx). They also employed a screen-printed silver grid on the rear side and a boron-doped emitter passivated with aluminum oxide (AlOx) and silicon nitride (SiNx) on the front.

One of the key concerns in the plating process was the potential for sodium chloride (NaCl)-induced degradation, especially on the front side of TOPCon devices. The team used a specialized Conifer plating tool to perform this critical process, ensuring the rear side was thoroughly contacted with the cathode electrode while the front side immersed in a copper sulfate (CuSO4) solution. An innovative bias-assisted light-induced plating (LIP) method was implemented with a constant current of around 150 mA during this immersion.

Results and Findings

The results of their experiments were astonishing. The Cu-plated solar cells showcased an initial efficiency boost of approximately 0.39% due to reduced grid resistance and an improved fill factor. After an extensive six-hour damp heat (DH) testing period, unprotected cells suffered over 80% efficiency degradation, whereas the Cu-plated counterparts experienced a mere 11.5% loss in performance.

Moreover, the innovative plating demonstrated its effectiveness through Transfer Length Method (TLM) measurements, showing that bare cells encountered a tenfold increase in contact resistivity after only 30 minutes. In stark contrast, the Cu-plated cells preserved significantly lower resistivity levels throughout extended testing periods.

Advanced Imaging Techniques

Advanced imaging techniques, including scanning electron microscopy (SEM) and energy-dispersive X-ray spectroscopy (EDS), revealed that Cu plating effectively filled voids in the silver contact, leading to a denser, more resilient interface that inhibits contaminant penetration and minimizes parasitic recombination.

Conclusion

"This accelerated test has proven that the Cu plating layer can significantly mitigate NaCl-induced degradation in DH conditions, ensuring improved stability for the device," concluded the scientists. Their research provides essential insights into enhancing the resilience of solar cells, a pivotal step as the world moves toward more sustainable energy solutions.

Their detailed findings are documented in the study titled "Alleviating Contaminant-Induced Degradation of TOPCon Solar Cells with Copper Plating," available now in the journal Solar Energy Materials and Solar Cells. The advances presented in this study could change the future of solar technology, positioning TOPCon cells as a leading contender in the ongoing quest for efficient and durable solar energy solutions!

Brasil (PT)

Brasil (PT)

Canada (EN)

Canada (EN)

Chile (ES)

Chile (ES)

Česko (CS)

Česko (CS)

대한민국 (KO)

대한민국 (KO)

España (ES)

España (ES)

France (FR)

France (FR)

Hong Kong (EN)

Hong Kong (EN)

Italia (IT)

Italia (IT)

日本 (JA)

日本 (JA)

Magyarország (HU)

Magyarország (HU)

Norge (NO)

Norge (NO)

Polska (PL)

Polska (PL)

Schweiz (DE)

Schweiz (DE)

Singapore (EN)

Singapore (EN)

Sverige (SV)

Sverige (SV)

Suomi (FI)

Suomi (FI)

Türkiye (TR)

Türkiye (TR)

الإمارات العربية المتحدة (AR)

الإمارات العربية المتحدة (AR)