Revolutionary Copper-Coated Basalt Fabric: A Game-Changer for CO₂ Reduction!

2025-05-27

Author: Siti

Transforming CO₂ into Ethanol: The Next Big Thing!

In a groundbreaking development, scientists have unveiled a novel method for converting carbon dioxide (CO₂) into valuable multi-carbon products, particularly ethanol — a crucial step toward sustainable energy and a carbon-neutral future.

The Challenge with Traditional Catalysts

While copper (Cu) is widely recognized as the go-to catalyst for producing these carbon-rich compounds, it comes with serious drawbacks. From low density and mechanical weakness to vulnerability in corrosive environments, copper has struggled to deliver the efficiency and stability researchers demand.

Enter Basalt Fiber Fabric: A High-Performance Alternative

Leading the charge in this innovative pursuit are Prof. Abudukeremu Kadier and Prof. Ma Pengcheng from the Xinjiang Technical Institute of Physics and Chemistry. Their recent study reveals basalt fiber fabric (BFF) as an exceptional supporting material for Cu catalysts. Why basalt? This natural resource boasts remarkable traits: it's lightweight, incredibly strong, highly resistant to chemicals, and strikingly affordable due to Xinjiang's rich basalt reserves.

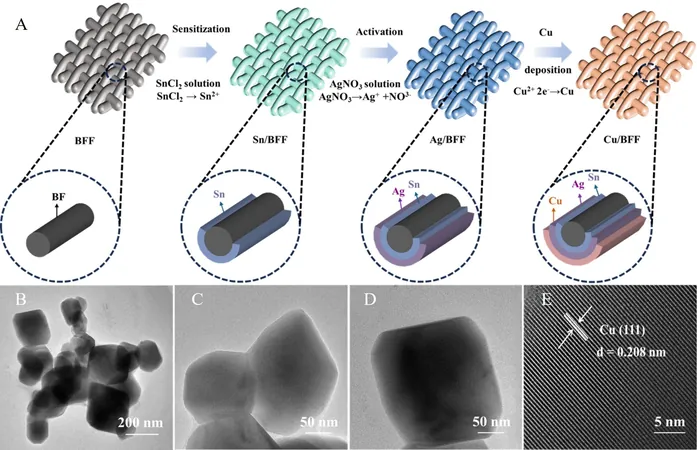

How They Did It: Crafting a Superior Catalyst

Utilizing a straightforward electroless Cu deposition process, the researchers crafted a catalytic platform that features a staggering 96.79% copper content. The results? A lightweight material, with a density of just 3.08 g/cm³ compared to copper's hefty 8.96 g/cm³, and impressive mechanical resilience and electrical conductivity.

Unprecedented Efficiency: Breaking Records in Ethanol Output

In tests using CO₂-saturated potassium bicarbonate electrolyte, this cutting-edge electrocatalyst achieved a current density of 25.93 mA/cm² and a jaw-dropping Faradaic efficiency of 97.01% for ethanol production! Increasing the electrolyte concentration to 1.5M took performance to new heights, hitting a current density of 184.51 mA/cm² and an incredible 98.02% efficiency.

Stability You Can Count On

One of the standout features of the Cu-deposited BFF is its durability. After 100 hours of continuous use, it retained 98.8% and 99.6% of its initial current density in varying concentrations of electrolyte. Such resilience is largely thanks to the fabric's robust mechanical strength and corrosion resistance, ensuring dependable performance in demanding conditions.

The Future is Bright — and Green

As the world grapples with the urgent need for sustainable solutions, this innovative copper-coated basalt fabric catalyst represents a promising leap forward in electrochemical CO₂ reduction technology. With its exceptional performance and durability, it could redefine the way we approach carbon conversion and energy efficiency.

Brasil (PT)

Brasil (PT)

Canada (EN)

Canada (EN)

Chile (ES)

Chile (ES)

Česko (CS)

Česko (CS)

대한민국 (KO)

대한민국 (KO)

España (ES)

España (ES)

France (FR)

France (FR)

Hong Kong (EN)

Hong Kong (EN)

Italia (IT)

Italia (IT)

日本 (JA)

日本 (JA)

Magyarország (HU)

Magyarország (HU)

Norge (NO)

Norge (NO)

Polska (PL)

Polska (PL)

Schweiz (DE)

Schweiz (DE)

Singapore (EN)

Singapore (EN)

Sverige (SV)

Sverige (SV)

Suomi (FI)

Suomi (FI)

Türkiye (TR)

Türkiye (TR)

الإمارات العربية المتحدة (AR)

الإمارات العربية المتحدة (AR)