Revolutionary Breakthrough: New Compound Prevents Explosive Risks in Polymer Production!

2025-05-07

Author: John Tan

Game-Changing Safety Measure for Industrial Polymerization

In a groundbreaking development, researchers have discovered that a compound known as TEMPO can significantly improve safety in the handling of the organic peroxide TBPB, a common ingredient in polymer synthesis. With its ability to inhibit free radical formation, TEMPO offers a powerful solution to the thermal hazards associated with TBPB's decomposition.

The Perils of TBPB: A Closer Look

TBPB is widely used in industries for its strong oxidative properties, but it comes with dangerous thermal risks. Sensitive to heat, shock, and friction, this compound is prone to explosive decomposition under the wrong conditions. Thus, ensuring its safe production, storage, and transportation is a priority for chemical manufacturers.

New Insights from Research

Published by a team from Nanjing Tech University, recent findings shed light on the thermal hazards posed by TBPB. While earlier studies have focused on safer synthesis methods, this research drills down into how TBPB can be controlled at the molecular level to mitigate risks.

Advanced Analytical Techniques Unveil Risks

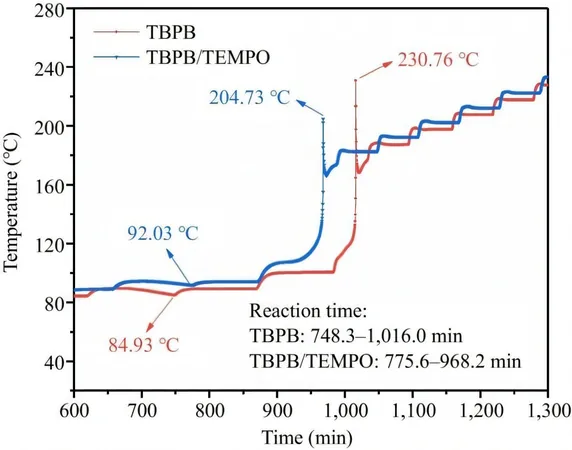

The researchers employed state-of-the-art analytical techniques, including differential scanning calorimetry (DSC), kinetic modeling, Fourier transform infrared (FTIR) spectroscopy, and electron paramagnetic resonance (EPR) spectroscopy. Their investigations revealed that TBPB's thermal decomposition is particularly aggressive between 100°C and 210°C, peaking dangerously at around 150°C with a significant heat release of 924.59 J/g.

Introducing TEMPO: The Safety Game-Changer

To combat these alarming risks, the researchers introduced TEMPO into the TBPB system. Remarkably, TEMPO mitigated the formation of dangerous free radicals, with EPR spectra confirming its effectiveness. Further evidence from calorimetry studies showed a notable drop in peak exothermic temperatures, reducing the overall heat release by almost 25% and lowering the pressure buildup dramatically.

A Safer Future for Chemical Manufacturing

With these promising results, incorporating TEMPO as a stabilizer could transform operational safety in environments where TBPB is handled. This innovative approach not only protects workers but also enhances process reliability and ensures safer transport of reactive chemicals, paving the way for a safer future in industrial polymerization and chemical synthesis.

Conclusions: A Major Step Forward

This research marks a significant leap forward in addressing the safety challenges posed by TBPB in chemical manufacturing. The implementation of TEMPO as a preventive measure could drastically reduce accident risks, making the handling of this volatile compound much safer.

Brasil (PT)

Brasil (PT)

Canada (EN)

Canada (EN)

Chile (ES)

Chile (ES)

Česko (CS)

Česko (CS)

대한민국 (KO)

대한민국 (KO)

España (ES)

España (ES)

France (FR)

France (FR)

Hong Kong (EN)

Hong Kong (EN)

Italia (IT)

Italia (IT)

日本 (JA)

日本 (JA)

Magyarország (HU)

Magyarország (HU)

Norge (NO)

Norge (NO)

Polska (PL)

Polska (PL)

Schweiz (DE)

Schweiz (DE)

Singapore (EN)

Singapore (EN)

Sverige (SV)

Sverige (SV)

Suomi (FI)

Suomi (FI)

Türkiye (TR)

Türkiye (TR)

الإمارات العربية المتحدة (AR)

الإمارات العربية المتحدة (AR)