Lunar Dust Revolutionizes Solar Power: The Key to Future Moon Colonies!

2025-04-06

Author: Daniel

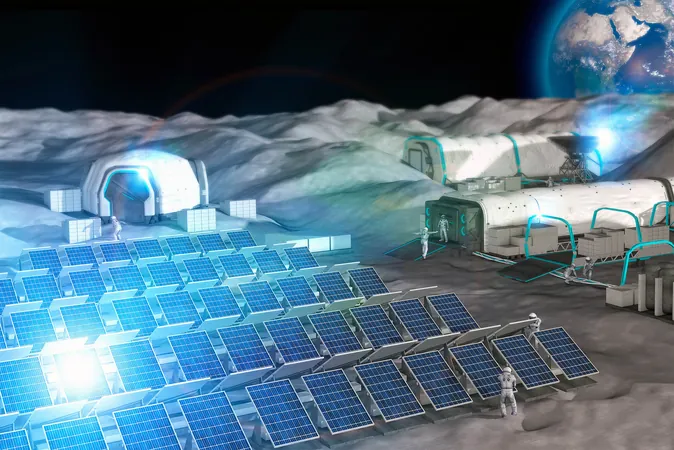

The Urgent Need for Lightweight Power Solutions in Space

While current solar panels used in space boast remarkable efficiencies of up to 30-40%, their hefty weight translates to astronomical launch costs—millions of dollars per kilogram. Felix Lang, the lead researcher from the University of Potsdam, emphasizes that the weight of solar cells significantly impacts the feasibility of lunar infrastructure.

To combat this issue, Lang and his team propose an ingenious solution: manufacturing solar cell components directly on the Moon using regolith—the fine, dusty substance that coats the lunar surface. This innovative approach dramatically reduces launch weight by a staggering 99.4% and costs by 99%, thereby unlocking exciting possibilities for Moon-based power systems.

Breaking Down the Production Process

The research team has developed a method to transform simulated lunar regolith into a new material dubbed moon-glass, which replaces conventional glass in solar technology. The incorporation of perovskite—a low-cost yet highly efficient crystal—allows for energy generation, achieving 22 to 50 watts per gram, vastly exceeding traditional solar setups.

Lang explains, “By drastically reducing weight, we can create many more cells on-site, eliminating the need for ultra-efficient designs that are costly and complicated to transport.” This not only streamlines energy production but also ensures radiative stability, as moon-glass is less prone to degradation over time compared to standard solar glass.

The Magic of Moon-Glass

One of the most remarkable attributes of moon-glass is its natural resistance to radiation, thanks to iron impurities in its composition. During testing, moon-glass solar cells maintained an impressive 99.6% of their original performance even after exposure to high-energy protons, showcasing their near-invulnerability in the harsh lunar environment. Furthermore, the optical properties of moon-glass remained robust, allowing thinner variants to achieve transparency of up to 80%, optimizing energy capture from sunlight.

A Simple Yet Effective Setup for Production

Creating moon-glass on the lunar surface could be achieved with minimal technological requirements. Concentrated sunlight could effectively melt regolith into glass, utilizing basic solar furnaces equipped with simple lenses or mirrors. Surprisingly, just one kilogram of perovskite from Earth combined with a ton of lunar soil could yield an astonishing 400 square meters of solar panels—enough to power initial lunar bases under the European Space Agency’s Artemis program.

The research predicts that lunar solar panels could achieve energy payback in as little as six months, dwarfing the often lengthy two-and-a-half-year return on investment typically associated with silicon solar cells.

How Lunar Solar Panels Stand Up Against Earthly Counterparts

The study explored multiple configurations of moon-glass solar cells, revealing efficiencies ranging from 8.6% to 12.3%. By utilizing thinner moon-glass and advanced contact materials, simulations suggest that efficiencies could climb to an impressive 21-23%, rivaling commercial solar panels produced on Earth—all while being infinitely easier to fabricate in a lunar environment.

Resilience Against Radiation: A Game Changer

Solar panels on the Moon face more severe radiation than those on the International Space Station. Nevertheless, the combination of perovskite and moon-glass ensures durability against exposure. Unlike conventional solar panels that degrade under radiation, moon-glass remains intact due to its unique properties, including the iron atoms’ ability to capture electrons and mitigate color shifts—making it a superior choice for space energy solutions.

Why Moon Dust Is the Future: Bridging Vision with Reality

For decades, scientists have fantasized about harnessing silicon from lunar regolith to create solar cells. However, the complex and resource-intensive process to achieve high-purity silicon can be prohibitively complicated. In stark contrast, the production of moon-glass and perovskite cells requires minimal tools and is significantly more radiation-resistant, promising greater longevity and lower costs.

As Lang reflects, “Be it extracting water for fuel or building lunar habitats, the potential of moon dust is vast. With the ability to convert it into solar cells, the energy needs of future lunar communities could be met right at their feet.”

The breakthrough reveals a tantalizing future where lunar settlements thrive on resources harvested from the Moon itself. Although a lunar city may still be on the horizon, its energy grid could be waiting—ready to spring to life from the very dust beneath our feet. This pioneering research opens new pathways for not only Moon exploration but also sustainable living beyond Earth, and the publication has sparked excitement across the scientific community about the possibilities of utilizing local materials to power human endeavors in space.

Brasil (PT)

Brasil (PT)

Canada (EN)

Canada (EN)

Chile (ES)

Chile (ES)

Česko (CS)

Česko (CS)

대한민국 (KO)

대한민국 (KO)

España (ES)

España (ES)

France (FR)

France (FR)

Hong Kong (EN)

Hong Kong (EN)

Italia (IT)

Italia (IT)

日本 (JA)

日本 (JA)

Magyarország (HU)

Magyarország (HU)

Norge (NO)

Norge (NO)

Polska (PL)

Polska (PL)

Schweiz (DE)

Schweiz (DE)

Singapore (EN)

Singapore (EN)

Sverige (SV)

Sverige (SV)

Suomi (FI)

Suomi (FI)

Türkiye (TR)

Türkiye (TR)

الإمارات العربية المتحدة (AR)

الإمارات العربية المتحدة (AR)