Groundbreaking Electric Method Revolutionizes Esterification Efficiency in Chemical Industries!

2025-01-23

Author: Yu

Groundbreaking Study in Esterification Efficiency

A groundbreaking study led by Prof. Yin Huajie from the Hefei Institutes of Physical Science, part of the esteemed Chinese Academy of Sciences, reveals a revolutionary approach to enhancing esterification reactions. These reactions play a crucial role across various sectors, including chemistry, perfumery, and pharmaceuticals, and the findings were recently highlighted in the prestigious journal Advanced Materials.

Challenges in Traditional Esterification Methods

Traditional esterification methods have long struggled with low reactivity and reversibility, making it challenging to achieve high yields. Often, manufacturers resort to adding excess alcohol or dehydrating agents, which can be costly and environmentally damaging, while complicating product separation.

Innovative JIC System for Improved Efficiency

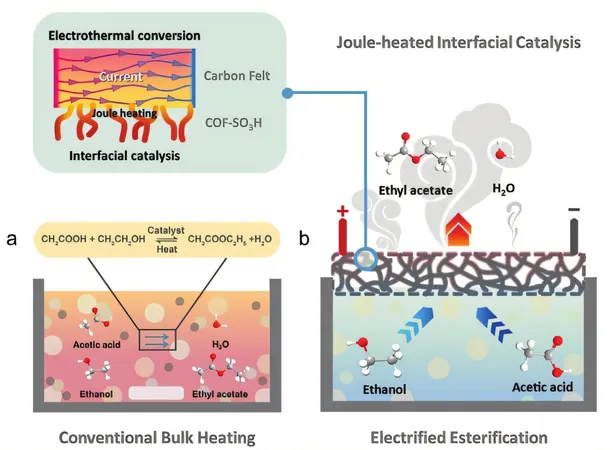

However, Prof. Yin and his team have devised a groundbreaking solution: the use of a Joule Heating Interface Catalytic (JIC) system to dramatically improve reaction efficiency. “What sets our research apart is the innovative combination of electrothermal sources with catalytic processes,” explained Prof. Yin, emphasizing the unique integration of these elements.

How the JIC System Works

This new JIC system utilizes Joule heating along with interface catalysis, effectively streamlining product separation throughout the esterification process, thereby enhancing reaction speed and efficiency. At the core of their method lies a specially designed catalyst fashioned from a sulfonic acid-functionalized covalent organic framework (COF-SO3H) paired with carbon felt to serve as the electrothermal source.

Impressive Results Achieved

Remarkably, when operated under optimal conditions with a balanced 1:1 ratio of reactants, the JIC system achieved an astonishing 80.5% conversion rate of acetic acid—significantly surpassing the conventional theoretical maximum of 62.5%.

Conclusion and Future Implications

This groundbreaking research not only paves the way for unprecedented efficiencies in esterification reactions but also champions a sustainable and energy-efficient pathway to enhance high-yield chemical processes across various industries. Stay tuned as this innovative work could redefine how industries approach esterification, potentially leading to more environmentally friendly practices in manufacturing and beyond!

Brasil (PT)

Brasil (PT)

Canada (EN)

Canada (EN)

Chile (ES)

Chile (ES)

Česko (CS)

Česko (CS)

대한민국 (KO)

대한민국 (KO)

España (ES)

España (ES)

France (FR)

France (FR)

Hong Kong (EN)

Hong Kong (EN)

Italia (IT)

Italia (IT)

日本 (JA)

日本 (JA)

Magyarország (HU)

Magyarország (HU)

Norge (NO)

Norge (NO)

Polska (PL)

Polska (PL)

Schweiz (DE)

Schweiz (DE)

Singapore (EN)

Singapore (EN)

Sverige (SV)

Sverige (SV)

Suomi (FI)

Suomi (FI)

Türkiye (TR)

Türkiye (TR)

الإمارات العربية المتحدة (AR)

الإمارات العربية المتحدة (AR)