Groundbreaking Discovery: Rare Quasicrystal Shapes Enhance Strength of 3D-Printed Aluminum Alloys!

2025-04-07

Author: Mei

Introduction

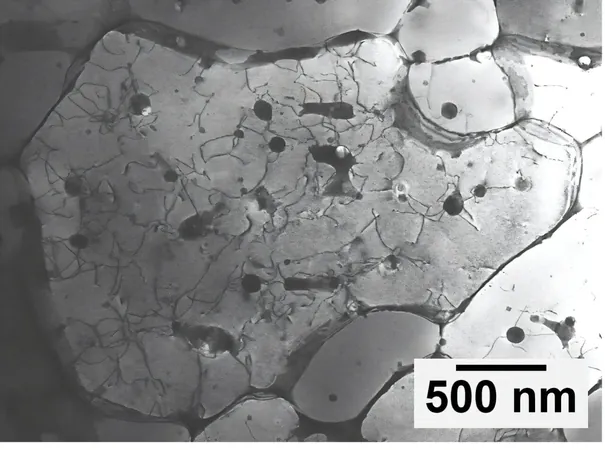

In an astonishing breakthrough, materials research engineer Andrew Iams made a remarkable discovery while peering through his electron microscope. During his examination of a novel aluminum alloy at the atomic level, he encountered an unexpected arrangement of atoms exhibiting a highly unusual pattern. "That's when I started to get excited," Iams remarked, as he speculated that he might have stumbled upon quasicrystals.

Significance of the Discovery

His excitement was not unwarranted. Along with his colleagues at the National Institute of Standards and Technology (NIST), Iams confirmed that these quasicrystals not only exist within this aluminum alloy but also contribute to its enhanced strength. Their ground-breaking findings have been published in the *Journal of Alloys and Compounds*, marking a significant advancement in materials science.

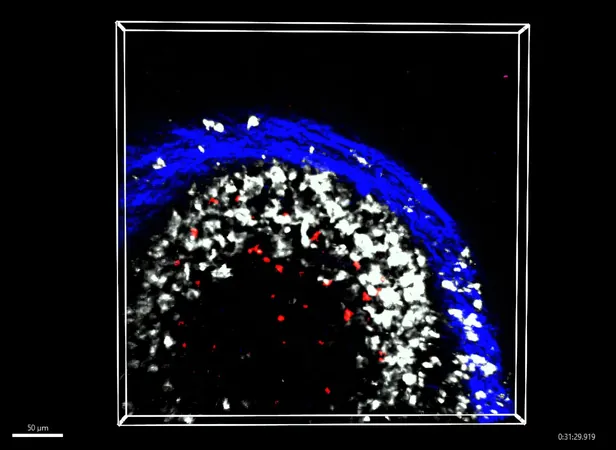

The aluminum alloy, which was formed under extreme conditions during 3D metal printing, holds the potential to revolutionize various industries. This advancement paves the way for the development of critical components in aeronautics, automotive manufacturing, and even energy systems, such as airplane parts, heat exchangers, and car chassis. Additionally, the research could inspire the creation of new aluminum alloys that leverage quasicrystals to maximize strength.

What Are Quasicrystals?

Quasicrystals differ significantly from ordinary crystals. While traditional crystals, such as table salt, are characterized by repeating atomic patterns—of which there are only 230 possible configurations—quasicrystals defy these norms. They are unique because they fill space without forming a repetitive pattern, effectively making them non-periodic.

The journey of quasicrystals began with Dan Shechtman, a materials scientist who discovered them in the 1980s while on sabbatical at NIST. Initially dismissed by many of his peers as flawed science, Shechtman triumphed in proving their existence, a feat that won him the Nobel Prize in Chemistry in 2011. Now, decades later, Iams has found quasicrystals in newly-developed 3D-printed aluminum—an exciting continuation of a transformative scientific legacy.

3D Metal Printing: A Game Changer in Manufacturing

The process of 3D metal printing is pushing boundaries with techniques like powder bed fusion, wherein layers of metal powder are melted together by a powerful laser. The result is intricate designs that are impractical or impossible to create with traditional manufacturing methods. A notable example is General Electric’s innovative fuel nozzles for jet engines, which are now printed as single lightweight components rather than being assembled from multiple heavier parts.

Despite its capabilities, 3D printing metal poses challenges, especially with high-strength aluminum alloys, which have traditionally been difficult to print due to the tendency of these materials to crack. "High-strength aluminum alloys are almost impossible to print," admits NIST physicist Fan Zhang, who contributed to the research.

The Challenges of Printing Aluminum Alloys

Aluminum has a low melting point around 700 degrees Celsius but requires significantly higher temperatures—over the boiling point of 2,470 degrees Celsius—for successful 3D printing. This extreme heating and cooling process can dramatically alter the metal’s properties. A breakthrough came in 2017 when researchers at HRL Laboratories and UC Santa Barbara developed a unique aluminum-zirconium alloy that could withstand the rigors of 3D printing.

The NIST team aimed to dissect the characteristics of this new alloy at an atomic level, recognizing the importance of understanding its structure for use in critical applications like military aircraft systems.

Unlocking the Secrets of Strength: The Role of Quasicrystals

It was during this investigation that the researchers uncovered the key to enhancing the alloy's strength: quasicrystals. Unlike uniform crystals that allow atoms to slip past each other easily, leading to weakness, quasicrystals disrupt the regular crystal patterns, introducing imperfections that fortify the metal.

Iams observed fivefold rotational symmetry when analyzing the crystal structures, a rare characteristic that signaled the presence of quasicrystals. Confirmation of their existence involved meticulous measurements from various angles to ensure the integrity of the findings.

With this innovative research, Zhang asserts, "We've shown that quasicrystals can make aluminum stronger. Now people may intentionally create them in future alloys." This discovery not only enhances our understanding of materials but also promises to usher in a new era of alloy design tailored for high-performance applications.

Conclusion

Stay tuned as science continues to break barriers, and the potential of quasicrystals turns the world of materials engineering upside down!

Brasil (PT)

Brasil (PT)

Canada (EN)

Canada (EN)

Chile (ES)

Chile (ES)

Česko (CS)

Česko (CS)

대한민국 (KO)

대한민국 (KO)

España (ES)

España (ES)

France (FR)

France (FR)

Hong Kong (EN)

Hong Kong (EN)

Italia (IT)

Italia (IT)

日本 (JA)

日本 (JA)

Magyarország (HU)

Magyarország (HU)

Norge (NO)

Norge (NO)

Polska (PL)

Polska (PL)

Schweiz (DE)

Schweiz (DE)

Singapore (EN)

Singapore (EN)

Sverige (SV)

Sverige (SV)

Suomi (FI)

Suomi (FI)

Türkiye (TR)

Türkiye (TR)

الإمارات العربية المتحدة (AR)

الإمارات العربية المتحدة (AR)