Groundbreaking Acoustic Wave Technology Transforms 3D Bioprinting at University of Melbourne

2024-11-08

Author: Li

Groundbreaking Acoustic Wave Technology Transforms 3D Bioprinting at University of Melbourne

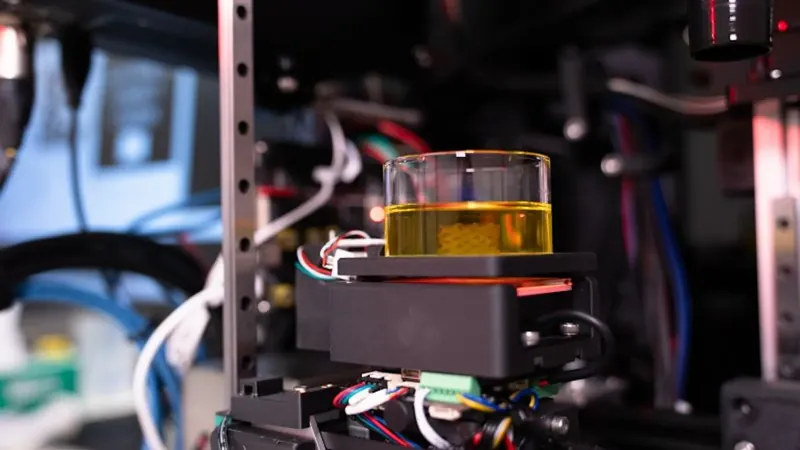

In an extraordinary leap forward for tissue engineering, researchers at the University of Melbourne's Collins BioMicrosystems Laboratory have unveiled a revolutionary 3D bioprinting technique called Dynamic Interface Printing (DIP). Spearheaded by biomedical engineer David Collins, this innovative approach dramatically improves the speed and efficiency of bioprinting by utilizing acoustic waves to guide cells into precise formations, a process that can create sophisticated human tissues in mere seconds.

DIP offers capabilities that traditional bioprinting methods simply cannot match. Conventional techniques typically involve a laborious layer-by-layer process, which not only slows production but also risks cell viability due to prolonged exposure times. In stark contrast, DIP can print structures approximately 350 times faster, significantly reducing the chance of cell damage while achieving unrivaled accuracy.

Collins elaborates on the limitations of existing technologies, stating, "Current 3D bioprinters depend on cells aligning naturally without guidance, which presents significant challenges." By harnessing the power of soundwaves, DIP precisely steers microscopic bubbles to position cells, thereby eliminating many of the risks that plague conventional bioprinting methods.

Advantages of Dynamic Interface Printing: Unmatched Versatility and Efficiency

One of the standout features of DIP is its ability to work with opaque materials and diverse biomaterials, all without the need for complicated optical systems. Unlike existing methods, DIP allows direct printing onto lab plates, minimizing the handling necessary after printing and thereby safeguarding cell viability. This advancement not only boosts the integrity of printed structures but also enhances the scalability for applications in both research and medicine.

DIP creates a unique environment that minimizes mechanical stress on cells, preserving their functionality—an essential factor for effectively creating viable tissue models. Its capability for intricate biofabrication also enables the production of complex multi-material structures that further expand its application scope in tissue engineering.

Future Implications in Healthcare

The prospect of rapidly producing patient-specific tissue models using DIP could revolutionize both research and personalized medical treatments. Researchers are already exploring improvements to the technology, including optimizing acoustic field control for even more precise cell arrangements. Imagine a future where medical facilities can bioprint hundreds of miniature tissue models, derived from a patient’s own cells, greatly enhancing the landscape for diagnostics, drug testing, and regenerative medicine.

Innovations Beyond DIP

The field of bioprinting is witnessed rapid advancements beyond this breakthrough. One new development features Ronawk's Bio-Blocks, which enable cells to thrive in 3D environments, closely mimicking natural biological conditions that foster improved cell health and functionality. This method enhances our understanding of cellular processes vital for the creation of novel biological therapies.

Additionally, the collaboration between BIO INX and Readily3D has birthed the READYGEL INX bioink, which utilizes low-light dose printing to fabricate intricate, cell-friendly structures quickly, further pushing the envelope on precision and efficiency in bioprinting.

As the world eagerly anticipates what lies ahead for 3D bioprinting, it's clear that innovations like Dynamic Interface Printing are set to redefine the possibilities, combining speed and accuracy to create a future enriched with personalized healthcare solutions and advanced medical models. Stay tuned as we witness these scientific advancements unfold!

Brasil (PT)

Brasil (PT)

Canada (EN)

Canada (EN)

Chile (ES)

Chile (ES)

Česko (CS)

Česko (CS)

대한민국 (KO)

대한민국 (KO)

España (ES)

España (ES)

France (FR)

France (FR)

Hong Kong (EN)

Hong Kong (EN)

Italia (IT)

Italia (IT)

日本 (JA)

日本 (JA)

Magyarország (HU)

Magyarország (HU)

Norge (NO)

Norge (NO)

Polska (PL)

Polska (PL)

Schweiz (DE)

Schweiz (DE)

Singapore (EN)

Singapore (EN)

Sverige (SV)

Sverige (SV)

Suomi (FI)

Suomi (FI)

Türkiye (TR)

Türkiye (TR)

الإمارات العربية المتحدة (AR)

الإمارات العربية المتحدة (AR)