Game-Changer in Biodegradable Implants: How Manufacturing Methods Impact Corrosion Resistance!

2025-07-18

Author: Daniel

Breakthrough Research on Bioabsorbable Alloys

In a groundbreaking study, researchers from IMDEA Materials, in partnership with the Helmholtz-Zentrum Hereon Institute of Surface Science and Meotec GmbH, have made waves by comparing the corrosion resistance of magnesium (Mg) and zinc (Zn) bioalloys produced through two distinct manufacturing techniques: extrusion and additive manufacturing.

The Key Findings

Published in the prestigious journal *Surface and Coatings Technology*, this pioneering research reveals that while both manufacturing methods result in biodegradable implants, their performance in terms of corrosion significantly differs. Surprisingly, samples created with Laser Powder Bed Fusion (LPBF) corroded at a much faster rate than those produced by traditional extrusion.

What’s Behind the Corrosion Rates?

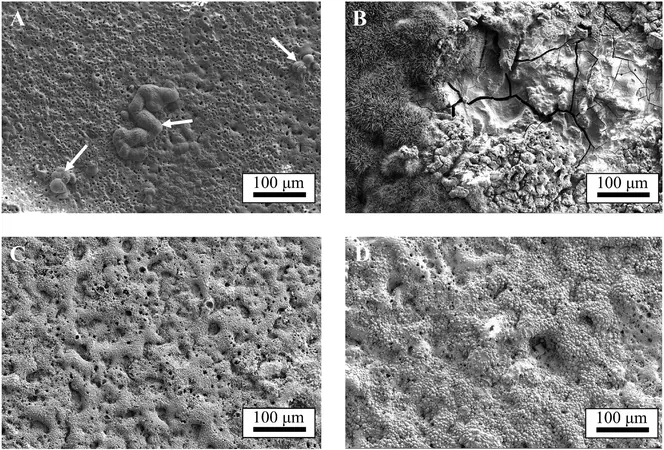

The higher degradation rate of LPBF samples in WE43 magnesium alloys was identified as being linked to yttrium oxide particles, which impede the formation of a protective corrosion layer. In the case of Zn1Mg alloys, the presence of more eutectic phases was found to drive microgalvanic degradation, further accelerating corrosion.

The Power of Plasma Electrolytic Oxidation (PEO)

To combat these corrosion challenges, the research team applied a plasma electrolytic oxidation (PEO) treatment, which effectively enhanced corrosion resistance across all tested samples. Guillermo Domínguez, the first author of the study, explained, "This treatment developed an oxide layer that vastly improved the protective qualities of the materials compared to those without treatment."

Surprising Outcomes with PEO Treatment

Interestingly, after applying PEO treatment, LPBF samples of Zn1Mg actually outperformed their extruded counterparts, showcasing the potential for improved longevity of implants. Conversely, while there was an enhancement seen in PEO-treated specimens, the WE43MEO LPBF samples still exhibited concerning corrosion rates due to variances in oxide layer thickness.

A Collaborative Effort Leading to Innovations

This research was part of the Horizon Europe BIOMET4D project, aimed at advancing biomaterials for medical applications. Conducted during Domínguez’s research tenure at the Helmholtz-Zentrum, it highlights the importance of collaborative efforts in scientific advancements.

A Brighter Future for Biodegradable Implants!

By optimizing manufacturing and surface treatment methods, this study lays the groundwork for safer and longer-lasting biodegradable implants. The implications for improved patient outcomes are monumental.

Brasil (PT)

Brasil (PT)

Canada (EN)

Canada (EN)

Chile (ES)

Chile (ES)

Česko (CS)

Česko (CS)

대한민국 (KO)

대한민국 (KO)

España (ES)

España (ES)

France (FR)

France (FR)

Hong Kong (EN)

Hong Kong (EN)

Italia (IT)

Italia (IT)

日本 (JA)

日本 (JA)

Magyarország (HU)

Magyarország (HU)

Norge (NO)

Norge (NO)

Polska (PL)

Polska (PL)

Schweiz (DE)

Schweiz (DE)

Singapore (EN)

Singapore (EN)

Sverige (SV)

Sverige (SV)

Suomi (FI)

Suomi (FI)

Türkiye (TR)

Türkiye (TR)

الإمارات العربية المتحدة (AR)

الإمارات العربية المتحدة (AR)